Packaging Design and Simulation Technology Market Size, Share, Trends, Growth and Forecast 2030

Packaging Design and Simulation Technology Market By Type (Software and Service), By End-use Industry (Consumer Goods, Food & Beverages, Pharmaceutical, Automotive, Consumer Electronics and Others) and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

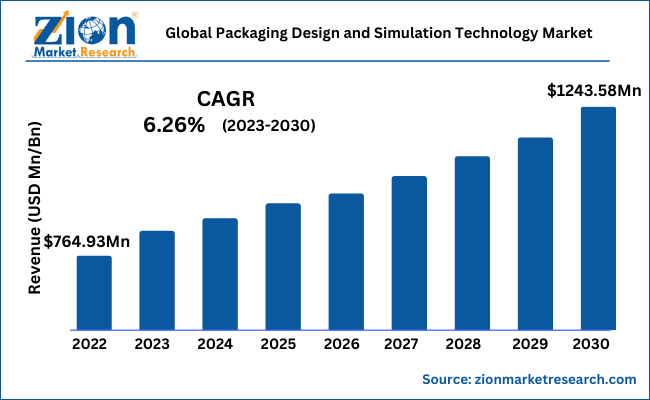

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 764.93 million | USD 1243.58 million | 6.26% | 2022 |

Packaging Design and Simulation Technology Industry Prospective:

Packaging Design and Simulation Technology offered efficient, cost-effective, and sustainable packaging solutions. The global packaging design and simulation technology market size was worth $764.93 M in 2022 and is set to surge $1243.58 M by 2030 with a CAGR of 6.26%.

Key Insights

- As per the analysis shared by our research analyst, the global packaging design and simulation technology market is estimated to grow annually at a CAGR of around 6.26% over the forecast period (2023-2030).

- In terms of revenue, the global packaging design and simulation technology market size was valued at around USD 764.93 million in 2022 and is projected to reach USD 1243.58 million, by 2030.

- Developing technology and changing the preference of companies to adopt simulation technology are projected to propel the packaging design and simulation technology market growth in the future.

- Based on the type, the software segment is expected to dominate the market during the forecast period.

- Based on the end-use industry, the automotive segment accounted for the largest market share in 2022.

- Based on region, North America is expected to dominate the market during the forecast period.

The report analyzes the global packaging design and simulation technology market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the packaging design and simulation technology industry.

Packaging Design and Simulation Technology Market: Overview

Innovative packaging plays an important role in the overall success of the market. Good quality materials are mandatory to be used for the packaging of the product. It should be enough tough to go through the entire product life cycle. Several suppliers are involved in product packaging; this process is accompanied by recalls, quality checks, and cost checks and hence gradually delays the overall process.

When it comes to determining whether or not a particular packaging design is useful and effective, simulation technology is an indispensable tool. It is easier to uncover possible problems, such as structural flaws, load-bearing capability, and transportation durability, when virtual prototypes are subjected to testing situations within a computer simulation. This preventative method reduces the need for expensive physical prototypes and revisions, which in turn saves time and costs.

Packaging Design and Simulation Technology Market: Growth Drivers

The rising automotive industry propels the market expansion

With the adoption of several technologies throughout its value chain, the automobile industry is undergoing a paradigm transition. The growth of simulation in the automobile industry is influenced by macrotrends like the development of autonomous cars and the push toward more efficient and electric vehicles. On the other hand, conventional demand for car simulation keeps gaining popularity. High-performance computer (HPC) simulation, utilizing computer-aided engineering (CAE) software, has gone a long way in enhancing and optimizing all areas of product development, including the manufacturing process, which was once employed by automakers for a restricted number of use cases in vehicle design. The same CAE simulation tools used in the vehicle design process are now employed to find the most effective and economical production methods. With the introduction of new materials like aluminum and plastics, simulation has become increasingly beneficial and allows producers to avoid the costly inefficiencies of the conventional trial-and-error method of developing the production process of a new vehicle. Thus, this is expected to drive the growth of the global packaging design and simulation technology market during the forecast period.

Packaging Design and Simulation Technology Market: Restraints

The growing trend of miniaturization is expected to hamper the market

The growing trend of electronic device shrinking has been spurred by the rapid advancement of microfabrication techniques. The problem of miniaturization lies in both design and production. A difficulty for IC packages is the pressure to obtain reduced form factors not only in the length and width directions but also in terms of package height. Greater power density produced by smaller volumes can have a negative influence on timing delays and increased resistance in copper/aluminum interconnects. At this size, there have never been physical design difficulties like this. Early in the design cycle, a comprehensive approach to chip design is necessary since the design margins have been significantly decreased. Thus, this is expected to hamper the packaging design and simulation technology industry growth.

Packaging Design and Simulation Technology Market: Opportunities

Wide adoption of simulation technology offers a lucrative opportunity

Numerous businesses use simulation technology extensively because it lowers production costs. The program aids in the creation and simulated testing of numerous prototypes. Additionally, it aids in achieving error-free output throughout a production process, preventing the manufacture of defective goods and the associated expenses. Additionally, it facilitates the reduction of R&D activity time. All of these elements are anticipated to promote packaging design and simulation technology industry expansion. In the past, manufacturers had to spend a lot of money inventing complicated machinery for their goods. Prototypes were readily available, but failure rates were significant, necessitating further R&D costs to lower such product failures.

Packaging Design and Simulation Technology Market: Challenges

High initial investment poses a major challenge to the market growth

The software needed for package design and simulation technologies requires extremely high initial costs. Additionally, sufficient training must be given to staff members for them to use this program correctly, which comes at a considerable cost. Thus, the high initial investment is expected to pose a major challenge to the packaging design and simulation technology market growth over the forecast period.

Packaging Design and Simulation Technology Market: Segmentation

The global packaging design and simulation technology industry is segmented based on type, end-use industry, and region.

Based on the type, the global market is bifurcated into software and service. The software segment is expected to dominate the market during the forecast period. The advantages of software, such as data security, dependability, and continuous testing, may be credited for this market segment's expansion. Finite element analysis is also anticipated to have a significant impact on the software segment's growth. FEA is often used to assess the quality, performance, and design of products in sectors including automotive, aerospace, defense, and electronics. On the other hand, the service segment is expected to grow at the fastest rate over the forecast period. The segment's expansion can be ascribed to governments and businesses being more aware of the virtual procedures employed for product creation. Services like design and consultation, implementation, and maintenance are becoming more and more popular with different businesses. One of the major companies in the industry, ANSYS Inc., offers expert advice and services for streamlining and compressing the simulation workflow.

Based on the end-use industry, the global packaging design and simulation technology industry is bifurcated into consumer goods, food & beverages, pharmaceutical, automotive, consumer electronics, and others. The automotive segment accounted for the largest market share in 2022 and is expected to show its dominance over the forecast period. The segment growth is owing to the early adoption of virtual tools for product development. Furthermore, a movement toward the utilization of electric and autonomous cars is also being seen in the automobile sector. The primary factor fueling the expansion of this market sector is the use of simulation to improve manufacturing processes in this sector.

Recent Developments:

- In April 2023, Huhtamaki, a leading provider of packaging solutions, redefined what is possible by employing science to create revolutionary mono-material technology. It's revolutionary, environmentally friendly flexible packaging in Paper, PE, and PP Retort satisfies the needs of both its clients and their end users.

- In March 2022, Powersim, a supplier of simulation and design tools for power electronics, including power supplies, motor drives, control systems, and microgrids, has been acquired by Altair, a leading global expert in computational science and artificial intelligence (AI). With the acquisition, power electronics are now a part of Altair's electronic system design technologies.

- In August 2022, Esko, a global developer of integrated hardware and software solutions for the print, packaging, and label industries, acquired Tilia Labs, an imposition A.I. software company, in a deal that addresses brand owners' and converters' need to connect and integrate the entire value chain through upstream digitalization. This purchase underscores the company's continuous commitment to offering integrated software and hardware solutions that speed the consumer-packaged goods go-to-market process.

- In January 2023, Oliver Inc. announced the acquisition of Tap Packaging + Design ("Tap Packaging"). Tap Packaging is a bespoke folding carton maker that serves customers in the food and beverage, beauty products, confection, health and wellness, and consumer goods industries. Oliver will be able to increase its product options and improve its position as the nation's biggest independent specialized packaging supplier as a result of this collaboration.

Packaging Design and Simulation Technology Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Packaging Design and Simulation Technology Market Research Report |

| Market Size in 2022 | USD 764.93 Billion |

| Market Forecast in 2030 | USD 1243.58 Billion |

| Growth Rate | CAGR of 6.26% |

| Number of Pages | 215 |

| Key Companies Covered | Altair Product Design Inc., MSC Software Corporation, Dassault Systemes, ANSYS Inc., NEFAB Group, Axiom Consulting, Mentor Graphics, ESI Group, Bosch Rexroth AG, AVID Technology Inc., Siemens, WHIZZ SYSTEMS, Cadence Design Systems, Inc, and PRE Technologies among others. |

| Segments Covered | By Type, By End-use Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Packaging Design and Simulation Technology Market: Regional Analysis

North America is expected to dominate the market during the forecast period

North America is expected to dominate the packaging design and simulation technology market over the forecast period. The growth in the region is attributed to the strong presence of major key players in the US and Canada. Moreover, this region is known as an early adopter of advanced technologies. Governments in the North American area are always concentrating on innovation and investment to create a greener working environment. Environmental restrictions are growing more rigorous in the region, and as a result, corporations are using simulators to verify product viability before producing it. Furthermore, the government's creative city projects in this region have significantly affected the adoption trend of simulation and analytic technologies to boost monitoring and improve surveillance.

The Asia-Pacific market is expected to rise significantly over the projected period owing to the growing automotive industry. According to PIB, during the 2021-22 fiscal year, two-wheelers and passenger automobiles accounted for 77% and 18% of the Indian automobile market, respectively. Small and midsized automobiles dominate passenger car sales. The total number of automobiles exported climbed from 4,134,047 in 2020-21 to 5,617,246 in 2021-22, representing a 35.9% increase.

As a result of India's fast urbanization, the Indian government has launched several programs to encourage the production and acceptance of electric cars in the country. These initiatives aim to reduce emissions and advance e-mobility. Initial interest in and exposure to electric mobility was aided by the National Electric Mobility Mission Plan (NEMMP) and Faster Adoption and Manufacturing of Hybrid & Electric Vehicles in India (FAME I and II). As of June 2021, 6,265 electric buses and 87,659 electric cars worth USD 117 million had been approved for different state and local transportation enterprises under phase two of the FAME plan. Thus, the government stated in 2021 that phase two of the FAME plan will be extended through 2024. By providing subsidies for e-buses, electric three-wheelers, electric passenger cars, and electric two-wheelers, this phase aims to electrify public and shared transportation. Thereby, driving the growth of the market in the region.

Packaging Design and Simulation Technology Market: Competitive Analysis

The global packaging design and simulation technology market is dominated by players like:

- Altair Product Design Inc.

- MSC Software Corporation

- Dassault Systemes

- ANSYS Inc.

- NEFAB Group

- Axiom Consulting

- Mentor Graphics

- ESI Group

- Bosch Rexroth AG

- AVID Technology Inc.

- Siemens

- WHIZZ SYSTEMS

- Cadence Design Systems Inc

- PRE Technologies

- Others.

The global packaging design and simulation technology market is segmented as follows:

By Type

- Software

- Service

By End-use Industry

- Consumer Goods

- Food & Beverages

- Pharmaceutical

- Automotive

- Consumer Electronics

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Innovative packaging plays an important role in the overall success of the market. Good quality materials are mandatory to be used for the packaging of the product. It should be enough tough to go through the entire product life cycle. Several suppliers are involved in product packaging; this process is accompanied by recalls, quality checks, and cost checks and hence gradually delays the overall process.

Growing industrial concerns regarding improved quality and brand portfolio through large R&D investments are anticipated to boost the global packaging design and simulation technology market in future. Companies’ initiatives to promote products with improved packaging design may positively impact global market growth in the future. Increasing consumer awareness towards recyclable products and packaging material used, whose feasibility is examined with simulation technology, is anticipated to contribute to global market growth.

According to the report, the global market size was worth around USD 764.93 million in 2022 and is predicted to grow to around USD 1243.58 million by 2030.

The global packaging design and simulation technology market is expected to grow at a CAGR of 6.26% during the forecast period.

The global packaging design and simulation technology market growth is expected to be driven by North America. It is currently the world’s highest revenue-generating market owing to the presence of major players in the region.

Which are the major players leveraging the packaging design and simulation technology market growth?

The global packaging design and simulation technology market is dominated by players like Altair Product Design Inc., MSC Software Corporation, Dassault Systemes, ANSYS Inc., NEFAB Group, Axiom Consulting, Mentor Graphics, ESI Group, Bosch Rexroth AG, AVID Technology Inc., Siemens, WHIZZ SYSTEMS, Cadence Design Systems, Inc, and PRE Technologies among others.

Choose License Type

List of Contents

Packaging Design and Simulation TechnologyIndustry Prospective:Key InsightsGrowth DriversRestraintsOpportunitiesChallengesSegmentationRecent Developments:Report ScopeRegional AnalysisCompetitive AnalysisThe global packaging design and simulation technology market is segmented as follows:By RegionHappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed