Epoxy Molding Compound Market Size, Share, Trends, Growth 2034

Epoxy Molding Compound Market By Type (Normal Epoxy Molding Compound, Green Epoxy Molding Compound, and High Thermal Conductivity Epoxy Molding Compound), By Application (Semiconductor Encapsulation, Electronic Components, and Automotive Components), By End-Use Industry (Electronics and Semiconductor, Automotive, Aerospace, Industrial, and Consumer Electronics) and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

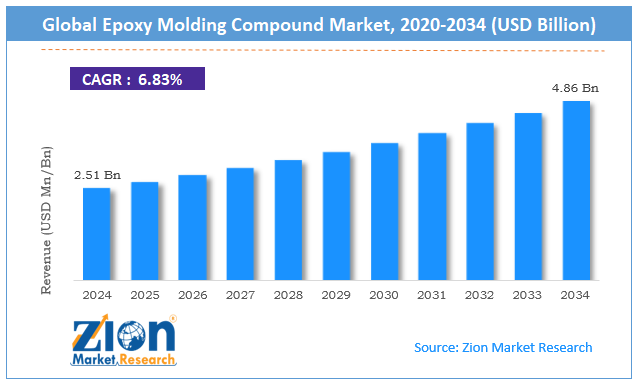

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.51 Billion | USD 4.86 Billion | 6.83% | 2024 |

Epoxy Molding Compound Industry Prospective:

The global epoxy molding compound market was valued at approximately USD 2.51 billion in 2024 and is expected to reach around USD 4.86 billion by 2034, growing at a compound annual growth rate (CAGR) of roughly 6.83% between 2025 and 2034.

Epoxy Molding Compound Market: Overview

An epoxy molding compound is a thermosetting plastic material that encapsulates and protects sensitive electronics from the environment (moisture, chemicals, mechanical stress). These special materials combine epoxy resins, hardeners, flame retardants, fillers, and release agents to make protective housings with excellent electrical insulation, mechanical strength, and thermal stability.

Modern epoxy molding compounds have low water absorption, reduced warpage, high adhesion strength, and increasingly environmentally friendly formulations. Applications range from microprocessor encapsulation to automotive electronics protection, with variations in composition to suit specific performance requirements (heat dissipation, chemical resistance, processing temperature).

The growing production of semiconductor devices, increasing miniaturization of electronics, and rising demand for reliable protection solutions in harsh operating environments are expected to drive substantial growth in the global epoxy molding compound industry over the forecast period.

Key Insights:

- As per the analysis shared by our research analyst, the global epoxy molding compound market is estimated to grow annually at a CAGR of around 6.83% over the forecast period (2025-2034)

- In terms of revenue, the global epoxy molding compound market size was valued at around USD 2.51 billion in 2024 and is projected to reach USD 4.86 billion by 2034.

- The epoxy molding compound market is projected to grow significantly due to rising 5G adoption, growth in renewable energy infrastructure, and demand for eco-friendly epoxy solutions, which drive the epoxy molding compound market.

- Based on type, green epoxy molding compound leads the segment and will continue to lead the global market.

- Based on the application, semiconductor encapsulation leads the market with the largest revenue share.

- Based on end-use industry, electronics and semiconductors are anticipated to command the largest market share.

- Based on region, North America is projected to lead the global market during the forecast period.

Epoxy Molding Compound Market: Growth Drivers

Electronics miniaturization and automotive electrification

The epoxy molding compound market is growing, driven by the miniaturization of electronics and the electrification of automotive systems across consumer and industrial segments. Modern integrated circuit designs have package sizes 60% smaller than previous generations and need protection from their complex environments.

Automotive electronics content has expanded, with the average vehicle now having 70-100 electronic control units that need reliable encapsulation solutions for high vibration and temperature variation.

Next-generation semiconductor technologies like 3D packaging, system-in-package, and heterogeneous integration create new opportunities for advanced encapsulation solutions with tailored performance characteristics.

Performance enhancement and environmental compliance

Innovation in the epoxy molding compound industry has made materials stronger, safer, and more efficient for electronics. New compounds can handle heat 3–5 times better, helping cool high-performance devices. Halogen-free and low-VOC versions meet tough environmental rules without losing performance.

Faster curing methods now cut production time by up to 40% and save energy. These materials also pass strict auto industry tests, working in extreme temperatures from -40°C to 150°C. Adding nanomaterials like silica and carbon has made them tougher and better at resisting moisture. These improvements are helping manufacturers meet the growing demands of next-generation electronics and electric vehicles.

Epoxy Molding Compound Market: Restraints

Raw material volatility and technical limitations

Despite growing demand, the epoxy molding compound market faces significant challenges related to supply chain vulnerabilities and inherent material performance constraints. Competitor encapsulation technologies, such as advanced polymers and conformal coatings, have advantages in specific applications, limiting the total addressable market.

High capital investment required for manufacturing facilities with specialized mixing, deaerating, and packaging capabilities creates barriers to entry and expansion in emerging markets. Technical limitations in heat dissipation remain a challenge for ultra-high-performance applications. Current compounds can’t meet thermal management requirements for next-generation computing and power electronics without dimensional constraints.

Epoxy Molding Compound Market: Opportunities

High-performance applications and sustainability initiatives

The epoxy molding compound industry has opportunities with specialized formulations for emerging electronics and green products. Power semiconductors made with silicon carbide and gallium nitride need encapsulation that can handle temperatures over 200°C while staying stable and protective. The rise in electric vehicle production is boosting demand for compounds that can protect power electronics under high heat and voltage.

At the same time, bio-based and renewable materials are becoming more popular as electronics companies push for greener supply chains. Advanced manufacturing techniques like automation and precision dispensing are also helping producers improve efficiency and meet growing demand across high-performance applications.

Epoxy Molding Compound Market: Challenges

Process integration and property balance

The epoxy molding compound market faces challenges in achieving optimal performance across demanding technical specifications while maintaining cost-effectiveness. Modern electronics need materials that work with fast, automated production and can safely cover delicate parts without defects.

Achieving the balance between properties such as high flow for complete filling versus minimal bleed during molding represents an ongoing technical challenge for formulators. Rapid innovation cycles in electronics design mean encapsulation materials must evolve quickly to meet new form factors and environmental requirements while maintaining backward compatibility with existing manufacturing infrastructure.

Epoxy Molding Compound Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Epoxy Molding Compound Market |

| Market Size in 2024 | USD 2.51 Billion |

| Market Forecast in 2034 | USD 4.86 Billion |

| Growth Rate | CAGR of 6.83% |

| Number of Pages | 212 |

| Key Companies Covered | Sumitomo Bakelite Co. Ltd., Hitachi Chemical Co. Ltd., Hysol Huawei Electronics Co. Ltd., Panasonic Corporation, KCC Corporation, Jiangsu Zhongpeng New Material Co. Ltd., Shin-Etsu Chemical Co. Ltd., Samsung SDI Co. Ltd., Kyocera Chemical Corporation, Chang Chun Group, Nama Chemicals, Hexion Inc., Henkel AG and Co. KGaA, Eternal Materials Co. Ltd., Kukdo Chemical Co. Ltd., Nagase ChemteX Corporation, Epoxy Base Electronic Material Corporation Ltd., Nitto Denko Corporation, Evonik Industries AG, DuPont de Nemours Inc., and others. |

| Segments Covered | By Type, By Application, By End-Use Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Epoxy Molding Compound Market: Segmentation

The global epoxy molding compound market is segmented into type, application, end-use industry, and region.

Based on type, the market is segregated into standard epoxy molding compound, green epoxy molding compound, and high thermal conductivity epoxy molding compound. Green epoxy molding compound leads the market due to increasing regulatory requirements for environmentally friendly electronics manufacturing, growing consumer preference for sustainable products, and the performance parity achieved between eco-friendly and conventional formulations.

Based on the application, the epoxy molding compound industry is classified into semiconductor encapsulation, electronic components, and automotive components. Semiconductor encapsulation holds the largest market share due to the continuous expansion of global semiconductor production, the essential protective function provided by encapsulation materials, and the high technical requirements that limit substitute materials in critical applications.

Based on the end-use industry, the market is divided into electronics and semiconductor, automotive, aerospace, industrial, and consumer electronics. The electronics and semiconductor segment is expected to lead the market during the forecast period due to the fundamental role of epoxy compounds in integrated circuit protection, the substantial volume of semiconductor devices manufactured globally, and the continuous innovation in electronic device design, creating new application requirements.

Epoxy Molding Compound Market: Regional Analysis

North America to lead the market

North America leads the global epoxy molding compound market due to its dominant position in global electronics manufacturing, extensive semiconductor production capacity, and continued industrial expansion. The region accounts for around 65% of the global market, with the U.S., Canada, and Mexico being the biggest consumption centers.

Manufacturing data shows the North American region produces over 70% of the world’s semiconductors and has the most advanced packaging facilities that require epoxy molding compounds. The region has well-established supply chains, technology expertise, and manufacturing infrastructure optimized for electronics production at scale.

Government policies supporting electronics manufacturing and semiconductor self-sufficiency initiatives drive additional investment in production capacity, requiring encapsulation materials. Lower manufacturing costs and the presence of major electronics OEMs and their suppliers give natural market advantages to regional epoxy molding compound producers.

Asia Pacific to maintain substantial market share.

Asia Pacific represents a significant epoxy molding compound market characterized by advanced semiconductor design, specialty electronics manufacturing, and high-performance application development. China, Taiwan, South Korea, and Japan are the biggest consumers in the region, particularly in aerospace, defense, automotive, and high-reliability electronics.

The area is focused on innovation and performance over cost, so there are opportunities for specialized, high-margin formulations to address unique technical requirements.

Strong research capabilities and collaboration between material suppliers and end-users enable customized solutions for demanding applications. Growing automotive electronics production, especially for electric vehicles and advanced driver assistance systems, creates new demand centers as regional automotive manufacturing becomes more electronic.

Recent Market Developments:

- In January 2025, Sumitomo Bakelite completed a new plant in China for epoxy resin molding compounds, with plans to begin full-scale mass production in 2025. This plant, located in the Suzhou Industrial Park, will increase the company's total production capacity by 1.3 times.

- In March 2025, Henkel Corporation launched a new portfolio of thermally conductive epoxy molding compounds engineered explicitly for electric vehicle power electronics with operating temperature capabilities up to 225°C.

Epoxy Molding Compound Market: Competitive Analysis

The global epoxy molding compound market is led by players like:

- Sumitomo Bakelite Co. Ltd.

- Hitachi Chemical Co. Ltd.

- Hysol Huawei Electronics Co. Ltd.

- Panasonic Corporation

- KCC Corporation

- Jiangsu Zhongpeng New Material Co. Ltd.

- Shin-Etsu Chemical Co. Ltd.

- Samsung SDI Co. Ltd.

- Kyocera Chemical Corporation

- Chang Chun Group

- Nama Chemicals

- Hexion Inc.

- Henkel AG and Co. KGaA

- Eternal Materials Co. Ltd.

- Kukdo Chemical Co. Ltd.

- Nagase ChemteX Corporation

- Epoxy Base Electronic Material Corporation Ltd.

- Nitto Denko Corporation

- Evonik Industries AG

- DuPont de Nemours Inc.

The global epoxy molding compound market is segmented as follows:

By Type

- Normal Epoxy Molding Compound

- Green Epoxy Molding Compound

- High Thermal Conductivity Epoxy Molding Compound

By Application

- Semiconductor Encapsulation

- Electronic Components

- Automotive Components

By End-Use Industry

- Electronics and Semiconductors

- Automotive

- Aerospace

- Industrial

- Consumer Electronics

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

An epoxy molding compound is a thermosetting plastic material that encapsulates and protects sensitive electronics from the environment (moisture, chemicals, mechanical stress).

The epoxy molding compound market is expected to be driven by expanding semiconductor production, increasing electronic content in automotive applications, growing demand for miniaturized electronics, rising adoption of electric vehicles, and technological advancements in compound formulations addressing thermal management challenges.

According to our study, the global epoxy molding compound market was worth around USD 2.51 billion in 2024 and is predicted to grow to around USD 4.86 billion by 2034.

The CAGR value of the epoxy molding compound market is expected to be around 6.83% during 2025-2034.

The global epoxy molding compound market will register the highest growth in North America during the forecast period.

Key players in the epoxy molding compound market include Sumitomo Bakelite Co., Ltd., Hitachi Chemical Co., Ltd., Hysol Huawei Electronics Co., Ltd., Panasonic Corporation, KCC Corporation, Jiangsu Zhongpeng New Material Co., Ltd., Shin-Etsu Chemical Co., Ltd., Samsung SDI Co., Ltd., Kyocera Chemical Corporation, Chang Chun Group, Nama Chemicals, Hexion Inc., Henkel AG and Co. KGaA, Eternal Materials Co., Ltd., Kukdo Chemical Co., Ltd., Nagase ChemteX Corporation, Epoxy Base Electronic Material Corporation Ltd., Nitto Denko Corporation, Evonik Industries AG, and DuPont de Nemours, Inc.

The report comprehensively analyzes the epoxy molding compound market, including an in-depth discussion of market drivers, restraints, emerging trends, regional dynamics, and future growth opportunities. It also examines competitive dynamics, technological innovations, material science advancements, and the changing performance requirements shaping the epoxy molding compound industry ecosystem.

Choose License Type

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed