3D Printer Nozzles Market Size, Share, Trends, Growth 2032

3D Printer Nozzles Market By Application (Aerospace, Medical Industry, Food & Beverages, Automotive, and Others), By Product Type (Hardened Steel, Stainless Steel, Brass, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

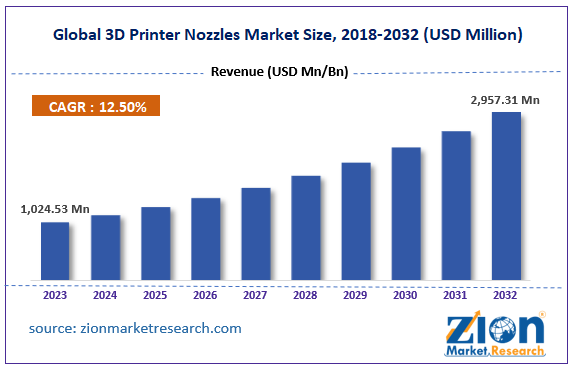

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 1,024.53 Million | USD 2,957.31 Million | 12.50% | 2023 |

3D Printer Nozzles Industry Prospective:

The global 3D printer nozzles market size was worth around USD 1,024.53 million in 2023 and is predicted to grow to around USD 2,957.31 million by 2032 with a compound annual growth rate (CAGR) of roughly 12.50% between 2024 and 2032.

3D Printer Nozzles Market: Overview

A nozzle in a 3D printer is the component that stores molten filament in the build section or area. It is a crucial component of 3D printers since it plays the vital role of delivering the base product, in this such molten filament, in the section where the final printing will occur. Currently, there are several types of 3D printer nozzles available in the market with each product offering specific advantages. Some examples of commonly used nozzles in 3D printers include Stainless Steel, V6 Volcano Brass, E3D Nozzle, M6 Thread Brass, and others. The contemporary brass nozzles are used during general-purpose 3D printing while superior-grade solutions are required for abrasive filaments. The quality of the nozzles defines the excellence of the final product. It is also helpful in determining the printing time. 3D printer nozzles are cost-efficient and are readily available. 3D printing is also known as additive manufacturing and is the opposite of subtractive production. 3D printers help in the production of objects or models in 3 dimensions using a digital 3D model or a computer-aided design (CAD) model. Over the years since their commercial launch, 3D printers have shown extended applications across industries including healthcare and construction thus driving the demand for supporting nozzles that can help deliver the final product. Awareness of the advantages and performance of each nozzle type is crucial to making the right purchasing decisions.

Key Insights:

- As per the analysis shared by our research analyst, the global 3D printer nozzles market is estimated to grow annually at a CAGR of around 12.50% over the forecast period (2024-2032)

- In terms of revenue, the global 3D printer nozzles market size was valued at around USD 1,024.53 million in 2023 and is projected to reach USD 2,957.31 million, by 2032.

- The market is projected to grow at a significant rate due to the growing demand for 3D printing solutions in the healthcare sector

- Based on the application, the medical industry segment is growing at a high rate and will continue to dominate the global market as per industry projection

- Based on the product type, the brass segment is anticipated to command the largest market share

- Based on region, North America is projected to dominate the global market during the forecast period

3D Printer Nozzles Market: Growth Drivers

Growing demand for 3D printing solutions in the healthcare sector will drive the market growth rate

The global 3D printer nozzles market is expected to grow due to the increasing demand for efficient 3D printers in the healthcare community. Modern technologies have allowed medical care to leverage 3D printers for drafting intricate scaffolds that are similar to the structure of human organs or tissues thus allowing improved patient care. The scaffolds help the cells in the body during the tissue regeneration process by delivering a basic structural framework. Apart from printing implants, 3D printing is also used for producing other medical devices such as surgical instruments, prosthetics, dental structures, and other medical devices. Moreover, the increasing growth in the biocompatible materials segment is further promoting the adoption of 3D printers in the global healthcare industry. In December 2023, the Nanyang Technological University and Singapore General Hospital (SGH) announced a partnership through which SGH patients will have access to customized medical implants and devices. The firms under the partnership will launch a Joint Research & Development Laboratory that will focus on 3D printing also known as additive manufacturing. In October 2023, Formlabs announced the launch of three novel 3D printing materials focusing on healthcare. Formlabs is a leading 3D printing technology provider and the new products are labeled BioMed Flex 80A Resin, BioMed Elastic 50A Resin, and IBT Flex Resin.

Increasing collaborations across industry players for leveraging 3D printing may impact nozzle demand

Nozzles in 3D printing devices play an important role. Thus, as the 3D printing industry evolves, the market for corresponding nozzles is likely to flourish. Since 3D printing has multiple applications, the industry is registering surging investments for improving the technology further and expanding its overall application. In March 2024, Apis Cor, a leading manufacturer of 3D printing robotic technologies announced that it had received strategic investments from D.R. Horton, a leading home builder in the US thus contributing to the demand in the global 3D printer nozzles market. D.R. Horton will leverage the offerings of Apis Cor to manage labor shortages in the industry.

3D Printer Nozzles Market: Restraints

High cost of 3D printing technology may restrict demand for nozzles

The global industry for 3D printer nozzles is expected to be restricted due to the high cost of the 3D printing technology. This equipment and the technology including software are expensive. Professional grade 3D printers cost more than USD 2500 depending on features and the deployed technology. Thus, 3D printing solutions have found only a limited number of buyers that can justify the associated cost. Standalone nozzles do not have much application until they are used with the entire setup limiting their adoption rate.

3D Printer Nozzles Market: Opportunities

Growing innovation in 3D printing technology may push market demand for high-performance nozzles

The global 3D printer nozzles market is expected to generate massive growth opportunities during the projection period. The growth rate will be driven by the increasing innovations in 3D printer systems allowing a higher scope of development of nozzle technology. In January 2023, Liqtra, a leading producer of 3D printers, announced the launch of LIQTRA FX-7 Pro 7. The new tool is fitted with multi-nozzle technology thus taking 3D printing a step ahead. LIQTRA FX-7 Pro has access to 7 nozzles in a single head and each nozzle control is independent of the rest thus improving the product’s overall performance by 300%. The geometric detailing of the new tool remains uncompromised. In addition to innovations in the 3D printing sector, market players are also experimenting with the nozzle technology itself. In June 2022, SPEE3D introduced a new high-velocity phase nozzle to be used in the world’s fastest metal printer. The newly launched nozzle can be used for a wide range of hard materials and was launched at the Cold Spray Action Team 2022 Conference. It uses nitrogen or compressed air to deposit the material at least 4 times faster than regular counterparts.

Automotive industry will fuel the industry’s demand rate during the projection period

3D printing has found multiple takers in the growing automotive industry. 3 dimensional printers have been used for producing several automotive parts including car bodies and more compact devices. While reports suggest the technology is expensive for mass car production, it has been showing wider applications in the production of car accessories. For instance, the 2025 Renault 5 E-Tech Electric vehicle is the most recent car to be equipped with 3D printed accessories. In October 2023, another automotive industry player Honda invested in Seurat Technologies by providing a fund of USD 99 million thus helping the global 3D printer nozzles market grow, Seurat deals with 3D-printed metal technology.

3D Printer Nozzles Market: Challenges

Deliver extensive material compatibility may challenge the expansion trajectory

The global 3D printer nozzles industry is likely to be challenged by the limited compatibility shown by this equipment with materials. 3D printer nozzles must be compatible with a wide range of base materials; however, the growing innovation in the material field may create issues for nozzle manufacturers since they must continue to adapt to the changing 3D printing material innovation rate.

3D Printer Nozzles Market: Segmentation

The global 3D printer nozzles market is segmented based on application, product type, and region.

Based on the application, the global market segments are aerospace, medical industry, food & beverages, automotive, and others. In 2023, the highest growth was witnessed in the medical industry segment driven by the growing use of 3D printers for producing an extensive range of medical devices. Additionally, 3D printers in healthcare have gained more investments in the last few years contributing to the segmental growth rate. As per official research, the healthcare 3D printing market is expected to reach over USD 10 million by the end of the decade.

Based on the product type, the global market divisions are hardened steel, stainless steel, brass, and others. In 2023, the highest revenue-generating segment was brass as the demand for brass-based nozzles is higher as compared to the other options. Brazz nozzles are relatively more cost-effective and have high thermal conductivity. Stainless steel has higher applications when dealing with materials used in the food and medical industry. The average cost of a standard brass nozzle is between USD 4 to USD 20.

3D Printer Nozzles Market Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | 3D Printer Nozzles Market |

| Market Size in 2023 | USD 1,024.53 Million |

| Market Forecast in 2032 | USD 2,957.31 Million |

| Growth Rate | CAGR of 12.50% |

| Number of Pages | 210 |

| Key Companies Covered | Zortrax, Ultimaker, FlashForge, Raise3D, Creality, Bondtech, MatterHackers, Anycubic, E3D, Prusa Research, Slice Engineering, Micro Swiss, LulzBot, MakerBot, BCN3D., and others. |

| Segments Covered | By Application, By Product Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

3D Printer Nozzles Market: Regional Analysis

North America will continue its dominance during the projection period

The global 3D printer nozzles market will witness higher growth in North America. The US is the leading region in terms of 3D printing technology driven by the early adoption of the novel engineering marvel in the country. Alongside this, the presence of several 3D printer producers further helps the region thrive. In May 2024, US-based Stratasys, a prominent player in the industry for 3D printers, materials, and software announced the launch of the H350 3D printer, Version 1.5 along with AF™ HighDef Printing capabilities offering finer detail printing and higher precision. The growing adoption of 3D printers in the regional healthcare sector will fuel higher demand in North America. In August 2023, Materialise, a pioneer in personalized medical solutions and 3D printing inaugurated its latest 3D printing facility thus delivering faster care and patient-oriented 3D printed medical implants in the US region. Europe is projected to grow at a significant pace driven by a growing focus on improving 3D printing solutions. Netherlands-based UltiMaker launched the UltiMaker S7 in March 2023. It is the latest offering in the company’s existing ‘S’ series of printers.

3D Printer Nozzles Market: Competitive Analysis

The global 3D printer nozzles market is led by players like:

- Zortrax

- Ultimaker

- FlashForge

- Raise3D

- Creality

- Bondtech

- MatterHackers

- Anycubic

- E3D

- Prusa Research

- Slice Engineering

- Micro Swiss

- LulzBot

- MakerBot

- BCN3D.

The global 3D printer nozzles market is segmented as follows:

By Application

- Aerospace

- Medical Industry

- Food & Beverages

- Automotive

By Product Type

- Hardened Steel

- Stainless Steel

- Brass

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A nozzle in a 3D printer is the component that stores molten filament in the build section or area.

The global 3D printer nozzles market is expected to grow due to the increasing demand for efficient 3D printers in the healthcare community.

According to study, the global 3D printer nozzles market size was worth around USD 1,024.53 million in 2023 and is predicted to grow to around USD 2,957.31 million by 2032.

The CAGR value of 3D printer nozzles market is expected to be around 12.50% during 2024-2032.

The global 3D printer nozzles market will witness higher growth in North America.

The global 3D printer nozzles market is led by players like Zortrax, Ultimaker, FlashForge, Raise3D, Creality, Bondtech, MatterHackers, Anycubic, E3D, Prusa Research, Slice Engineering, Micro Swiss, LulzBot, MakerBot and BCN3D.

The report explores crucial aspects of the 3D printer nozzles market including detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed