Aluminum Forging Market Size, Share, Trends, Growth 2030

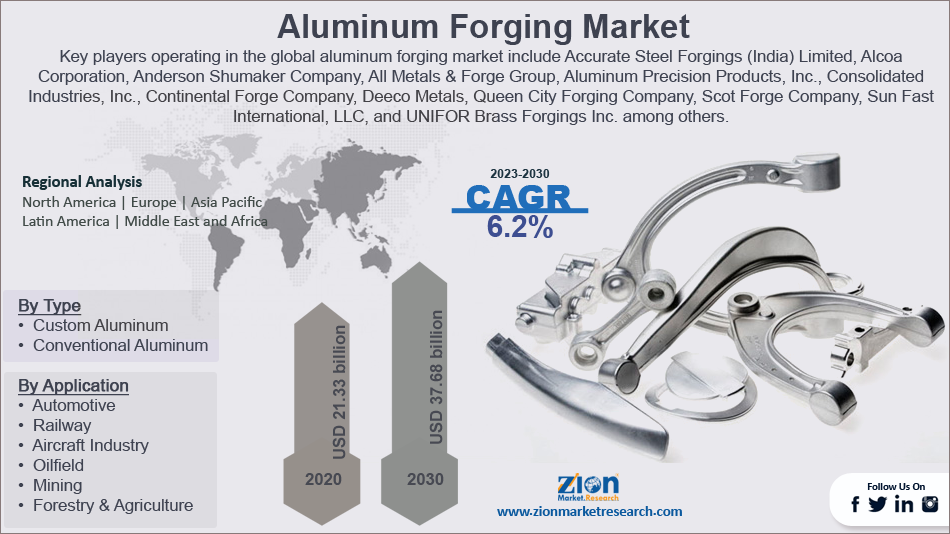

Aluminum Forging Market By Type (Custom Aluminum Forging, Conventional Aluminum Forging) By Application (Automotive, Railway, Aircraft Industry, Oilfield, Mining, Forestry & Agriculture, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

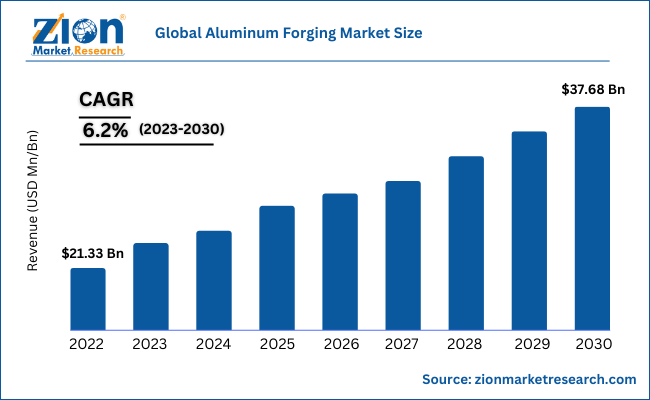

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 21.33 Billion | USD 37.68 Billion | 6.2% | 2022 |

Aluminum Forging Industry Prospective:

The global aluminum forging market size is set for rapid growth over the forecast period. In terms of revenue, the global aluminum forging market accounted for USD 21.33 Billion in 2022 and is expected to reach USD 37.68 Billion by 2030, growing at a CAGR of 6.2% during the forecast period.

The market report offers quantitative and qualitative insights into the key drivers, opportunities, constraints, and challenges impacting the global aluminum forging market industry.

Aluminum Forging Market: Overview

Aluminum forging is an industrial process that is carried out before high-strength forged aluminum pieces are produced by pounding the aluminum or vigorous squeezing. For parts used in applications that require protection and superior strength, aluminum forgings are perfect. Aluminum is highly used in numerous end-user industries such as construction, military, automotive, electrical, and others.

Aluminum forging products are employed in modern vehicles to make them lighter, safer, and eco-friendly. As low-fuel-consumption cars have been requested for the economy in recent years, the automotive industry is one of the largest consumers of aluminum-forged components. The deformation rate and the solid temperature are the main factors impacting the enforceability of aluminum alloys. Most of the alloys are forged at nearly 55 °C (100 °F) below the respective solid temperature.

Key Insights

- As per the analysis shared by our research analyst, the global aluminum forging market is expected to grow annually at a promising CAGR of around 6.2% during the forecast period 2023-2030.

- In terms of revenue, the global aluminum forging market size was valued at around USD 21.33 billion in 2022 and is expected to reach USD 37.68 billion by 2030.

- Based on type, the custom aluminum segment held the largest market share in 2022.

- Based on application, the automotive segment held the dominating market share in 2022.

- Based on region, the Asia-Pacific region held the largest market share in 2022.

Aluminum Forging Market: Growth Factors

Extensive application of aluminum forging in various industries such as defense, automotive, aerospace, and others drive the growth of the market

The global aluminum forging market is primarily driven by the increasing demand for lightweight materials in the transportation industry, including automotive, aerospace, and marine. Aluminum forgings offer a high strength-to-weight ratio and excellent corrosion resistance, making them ideal for use in structural and safety components of vehicles and aircraft. The growth of renewable energy sectors such as wind and solar power is also driving the demand for aluminum forgings in the manufacturing of turbines and frames. Additionally, the rising demand for aluminum forgings in the defense industry for armor plating and other applications is further fueling the growth of the market.

Aluminum Forging Market: Restraints

Fluctuations in the prices of raw materials and the requirement for high capital investment might hinder the growth of the market

The global aluminum forging market faces some restraints that can hamper its growth prospects. One of the major challenges is the volatility of aluminum prices, which can affect the profit margins of manufacturers. Another restraint is the high capital investment required for setting up forging facilities, which can deter new entrants to the market. Moreover, the increasing popularity of alternative materials such as composites and plastics in certain applications may also pose a threat to the growth of the aluminum forging market.

Aluminum Forging Market: Opportunities

Rise in inclination towards renewable energy sources and the development of new forging technologies create ample opportunities for the industry

Despite the challenges, the aluminum forging market presents several opportunities for growth and development. The increasing demand for electric vehicles, particularly in developing countries, is expected to drive the demand for the aluminum forging industry as they offer superior mechanical and thermal properties compared to conventional materials.

The growth of the construction industry, especially in developing economies, also presents a significant opportunity for the market, as aluminum forgings are widely used in the construction of structural components such as beams and columns. The trend towards lightweighting and fuel efficiency in the aviation industry is also expected to boost the demand for aluminum forgings in the manufacturing of aircraft components.

Additionally, the increasing focus on renewable energy sources such as wind and solar power presents a significant opportunity for the market, as aluminum forgings are widely used in the production of wind turbines, solar panels, and related components. Moreover, the development of new forging technologies and processes is expected to drive innovation in the market, opening up new avenues for growth and profitability.

Aluminum Forging Market: Challenges

Environmental impact of forging process and threat of using substitutes might act as a challenge for the market

The aluminum forging industry faces challenges such as intense competition from alternative materials, especially in the automotive and aerospace industries. Another challenge is the need for high levels of customization and precision in the production of forgings, which can be time-consuming and expensive. The availability of raw materials and the environmental impact of aluminum forging processes are also emerging challenges that the market needs to address.

Aluminum Forging Market: Segmentation

The global aluminum forging market is segmented based on type, application, and region.

Based on type, the market is bifurcated into custom aluminum forging and conventional aluminum forging segments. The custom aluminum forging segment held the largest market share in 2022 and is further predicted to grow rapidly at a significant CAGR during the forecast period. The growth of this segment is mainly due to the increasing demand for highly specialized and customized components in industries such as aerospace, defense, and automotive. Custom aluminum forging allows for the production of complex shapes, intricate features, and precise tolerances that are required in these industries.

Additionally, the growing trend towards lightweight and high-strength components is driving the demand for custom aluminum forging, as it allows for the production of components with superior mechanical properties. The increasing investment in research and development in the aluminum forging industry is also expected to further drive the growth of the segment.

Based on application, the market is segmented into automotive, railway, aircraft industry, oilfield, mining, forestry & agriculture, and others. The automotive segment held the largest market share in 2022 and is further predicted to grow at a notable CAGR during the forecast period. This is mainly due to the increasing demand for lightweight and high-strength components in the automotive industry. Forged aluminum components are widely used in automotive suspension systems, engine parts, and wheels. The growing trend towards electric vehicles and the need for lightweight components in conventional vehicles is expected to further drive the growth of the segment in the aluminum forging industry.

Recent Developments

- In February 2022, Precision Castparts Corp. announced the completion of its acquisition of Noranco Inc., a provider of aluminum forging and machining services. The acquisition is expected to strengthen Precision Castparts' position in the aerospace industry and provide opportunities for growth in other markets.

- In January 2022, Arconic Corporation announced the expansion of its forging operations in Europe with the acquisition of the Morriston-Radomsko business in Poland. The acquisition includes two forging facilities and a machining center that will help Arconic expand its product portfolio and strengthen its position in the European market.

Aluminum Forging Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Aluminum Forging Market Research Report |

| Market Size in 2022 | USD 21.33 Billion |

| Market Forecast in 2030 | USD 37.68 Billion |

| Growth Rate | CAGR of 6.2% |

| Number of Pages | 215 |

| Key Companies Covered | Accurate Steel Forgings (India) Limited, Alcoa Corporation, Anderson Shumaker Company, All Metals & Forge Group, Aluminum Precision Products, Inc., Consolidated Industries, Inc., Continental Forge Company, Deeco Metals, Queen City Forging Company, Scot Forge Company, Sun Fast International, LLC, and UNIFOR Brass Forgings Inc. among others. |

| Segments Covered | By Type, By Application, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Aluminum Forging Market: Regional Analysis

Asia-Pacific region held the largest market share in 2022

Based on region, the Asia-Pacific region held the largest global aluminum forging market share in 2022 and is further predicted to grow rapidly at an impressive CAGR during the forecast period. The Asia Pacific region is expected to experience significant growth in the aluminum forging market due to several factors. The region is home to emerging economies such as China and India, which have a large and rapidly growing manufacturing sector. The increasing investment in infrastructure and construction activities in the region is also driving the demand for aluminum forging components. Additionally, the growing demand for lightweight and high-strength components in the region in industries such as aerospace, defense, and automotive is expected to further drive market growth.

Furthermore, the Asia Pacific region has a large population and a rising middle class, which is driving the demand for automobiles and consumer electronics. This is expected to increase the demand for aluminum forging components in these industries as well. The region also has favorable government policies and initiatives supporting industrial growth, which is expected to further boost the aluminum forging industry growth.

Aluminum Forging Market: Competitive Players

Key players operating in the global aluminum forging market include:

- Accurate Steel Forgings (India) Limited

- Alcoa Corporation

- Anderson Shumaker Company

- All Metals & Forge Group

- Aluminum Precision Products Inc.

- Consolidated Industries Inc.

- Continental Forge Company

- Deeco Metals

- Queen City Forging Company

- Scot Forge Company

- Sun Fast International LLC

- UNIFOR Brass Forgings Inc.

- Among Others.

The Aluminum Forging Market is segmented based on:

By Type

- Custom Aluminum Forging

- Conventional Aluminum Forging

By Application

- Automotive

- Railway

- Aircraft Industry

- Oilfield

- Mining

- Forestry & Agriculture

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Aluminum forging is an industrial process that is carried out before high-strength forged aluminum pieces are produced by pounding the aluminum or vigorous squeezing. For parts used in applications that require protection and superior strength, aluminum forgings are perfect. Aluminum is highly used in numerous end-user industries such as construction, military, automotive, electrical, and others.

The global aluminum forging market is predicted to increase at a CAGR of 6.2% during the forecast period.

The global aluminum forging market was worth around USD 21.33 billion in 2022 and is expected to reach USD 37.68 billion by 2030.

The global mobile hotspot market is being driven by several factors, including the growing demand from industries such as aerospace, automotive, and defense, which require lightweight and high-strength components. Additionally, the increasing adoption of aluminum in various applications, such as electrical and construction, is expected to fuel market growth.

Asia-Pacific held a notable share in the global aluminum forgings market in 2022 and is likely to grow the fastest during the forecast period. The growth of the global aluminum forgings market in Asia-Pacific is being driven by factors such as the growing demand for lightweight components in various end-use industries, coupled with the increasing investment in infrastructure and construction activities. Additionally, favorable government policies and initiatives supporting industrial growth are expected to further boost market growth.

Some of the major companies operating in the mobile hotspot market include Accurate Steel Forgings (India) Limited, Alcoa Corporation, Anderson Shumaker Company, All Metals & Forge Group, Aluminum Precision Products, Inc., Consolidated Industries, Inc., Continental Forge Company, Deeco Metals, Queen City Forging Company, Scot Forge Company, Sun Fast International, LLC, and UNIFOR Brass Forgings Inc. among others.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed