Bearing Isolators Market Size, Share, Trends, Growth and Forecast 2032

Bearing Isolators Market - By Material Type (Metallic and Non-Metallic), By End-Use Industry (Chemical Processing, Oil & Gas, Paper & Pulp, Mining, Manufacturing & Processing, and Metal Processing), And By Region - Global Industry Perspective, Comprehensive Analysis, and Forecast, 2024 - 2032

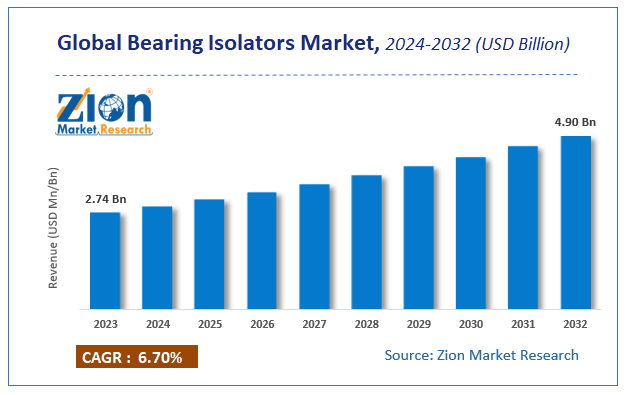

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

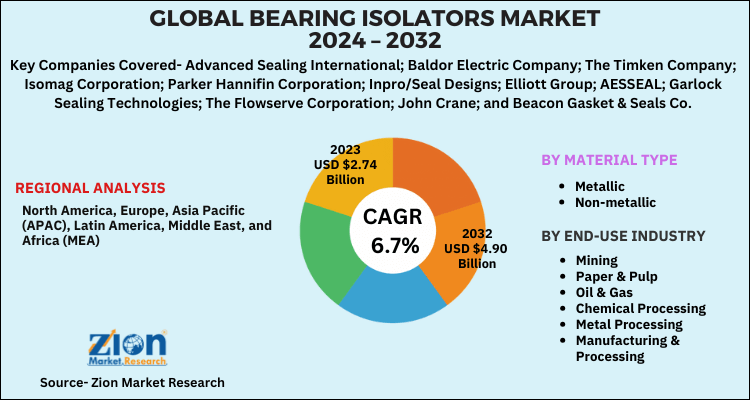

| USD 2.74 Billion | USD 4.90 Billion | 6.7% | 2023 |

Bearing Isolators Market Insights

According to Zion Market Research, the global Bearing Isolators Market was worth USD 2.74 Billion in 2023. The market is forecast to reach USD 4.90 Billion by 2032, growing at a compound annual growth rate (CAGR) of 6.7% during the forecast period 2024-2032.

The report offers a comprehensive analysis of the market, highlighting the factors that will determine growth, potential challenges, and opportunities that could emerge in the Bearing Isolators industry over the next decade.

Bearing Isolators Market: Overview

The bearing isolator is defined as non-wearing, non-contact, and permanent bearing protection equipment. Apparently, the equipment includes a stator and rotor that are bound together and inseparable during the device operations. The product is also utilized in the process of lubrication and helps in keeping out contamination. Moreover, the bearing isolators are made up of bronze metals that make use of vapor-blocking characteristics along with facilitating the transfer of vapor contamination during equipment rotation. These products are cost-effective substitutes for face seals and lip seals and can perform proficiently with respect to the enhancement of bearing protection ability. They offer two-way sealing protection to the rotating device that facilitates the extension of the bearing life span.

Bearing Isolators Market: Growth Dynamics

The expansion of the bearing isolators industry over the forecast timespan is credited to large-scale awareness pertaining to benefits provided by the product along with its escalating popularity across oil & gas, manufacturing & processing, mining, paper & pulp, and chemical processing. In addition to this, rapid industrialization witnessed across the globe is predicted to account for a lucrative surge in the growth of the market over the forecasting years. The massive need for lubrication due to the rise in the proportion of industrial damage will translate into huge demand for the product over the forthcoming years.

Furthermore, bearing isolators assist in minimizing downtime costs, minimize replacement costs, and repair costs. The growing necessity to prevent rusting of machines will further accentuate the growth of the bearing insulators industry over the forthcoming years. Nonetheless, escalating costs of speed sensors and fluctuating product costs are a few of the hurdles in the growth path of the market.

The Bearing Isolators Market is experiencing steady growth due to several key factors that drive demand across industries. The following are the major growth dynamics:

1. Increased Industrial Automation

-

The growing adoption of automation in industries such as manufacturing, oil & gas, and food & beverage is boosting the demand for bearing isolators. These isolators protect bearings from contaminants and increase the lifespan of machinery, reducing downtime and maintenance costs.

2. Rising Demand for Reliability and Maintenance-free Operations

-

Bearing isolators are known for improving equipment reliability and extending bearing life by preventing leakage and contamination. Industries that prioritize continuous operations, such as power generation and chemical processing, are increasingly adopting these solutions to reduce unscheduled maintenance.

3. Expansion in Heavy Industries

-

Sectors such as mining, oil & gas, and marine industries, where equipment is exposed to harsh environmental conditions, are seeing an increased demand for bearing isolators. These isolators offer protection against dust, water, chemicals, and other contaminants, thus enhancing equipment durability.

4. Emphasis on Energy Efficiency

-

Bearing isolators reduce friction and protect the integrity of machinery, contributing to overall energy efficiency. As industries focus on optimizing energy use, the adoption of technologies that reduce wear and tear on mechanical components has increased.

5. Growth in Renewable Energy Sector

-

The expansion of renewable energy sources, especially wind and hydroelectric power, is driving demand for bearing isolators. Wind turbines and hydroelectric equipment have critical rotating components that require effective sealing to ensure efficient and long-lasting operation.

6. Technological Advancements in Bearing Isolators

-

Innovations in materials (such as non-metallic, corrosion-resistant options) and designs (including labyrinth seals and advanced sealing technologies) have resulted in bearing isolators that provide better performance in harsh environments. This has opened up new applications for bearing isolators across industries.

7. Regulations and Environmental Standards

-

Stricter environmental regulations regarding oil leakage and contamination have increased the need for effective sealing solutions in various industries. Bearing isolators, which prevent lubricant leakage, help industries comply with these regulations and avoid environmental penalties.

8. Increased Focus on Predictive Maintenance

-

Predictive maintenance programs, which rely on monitoring the condition of equipment to predict failures, are becoming more popular in industries. Bearing isolators play a key role in protecting bearings and improving machine uptime, making them an essential component in predictive maintenance strategies.

9. Replacement and Retrofitting Demand

-

The growing trend of replacing conventional seals with bearing isolators to improve equipment performance is driving market growth. Many industries are retrofitting their existing machinery with modern bearing isolators to enhance efficiency and reliability.

10. Growing Industrialization in Emerging Markets

-

Rapid industrialization in emerging economies, such as China, India, and Brazil, is creating significant demand for industrial equipment, including bearing isolators. This growth is driven by infrastructure development and the expansion of manufacturing activities in these regions.

11. Increased Focus on Sustainability

-

Bearing isolators help reduce lubricant leakage and minimize contamination, contributing to sustainability efforts across industries. As more companies adopt green practices, the demand for such solutions is expected to rise.

These factors, combined with the expanding application of bearing isolators in different industrial sectors, are expected to drive the growth of the market over the coming years.

Bearing Isolators Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Bearing Isolators Market |

| Market Size in 2023 | USD 2.74 Billion |

| Market Forecast in 2032 | USD 4.90 Billion |

| Growth Rate | CAGR of 6.7% |

| Number of Pages | 110 |

| Key Companies Covered | Advanced Sealing International; Baldor Electric Company; The Timken Company; Isomag Corporation; Parker Hannifin Corporation; Inpro/Seal Designs; Elliott Group; AESSEAL; Garlock Sealing Technologies; The Flowserve Corporation; John Crane; and Beacon Gasket & Seals Co |

| Segments Covered | By Material Type, By End-Use Industry And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Bearing Isolators Market: Regional Insights

North America To Gain Dominance In Global Market In Terms of Revenue By 2032

The regional market surge over the estimated timespan is attributed to humungous product demand in the industries like mining, oil & gas, and manufacturing & processing in the countries like the U.S. In addition to this, new product launches by the established players and acceptance of new business strategies by the entrants in the region will promulgate the regional industry growth over the forthcoming years.

Bearing Isolators Market: Competitive Space

Key participants included in the study are -

- Advanced Sealing International

- Baldor Electric Company

- The Timken Company

- Isomag Corporation

- Parker Hannifin Corporation

- Inpro/Seal Designs

- Elliott Group

- AESSEAL

- Garlock Sealing Technologies

- The Flowserve Corporation

- John Crane

- Beacon Gasket & Seals Co.

The global bearing isolators market is segmented as follows:

By material type:

- Metallic

- Non-metallic

By end-use industry:

- Mining

- Paper & Pulp

- Oil & Gas

- Chemical Processing

- Metal Processing

- Manufacturing & Processing

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of The Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The expansion of bearing isolators industry over the forecast timespan is credited to large-scale awareness pertaining to benefits provided by the product along with its escalating popularity across oil & gas, manufacturing & processing, mining, paper & pulp, and chemical processing.

Global Bearing Isolators Market was worth USD 2.74 Billion in 2023. The market is forecast to reach USD 4.90 Billion by 2032, growing at a compound annual growth rate (CAGR) of 6.7% during the forecast period 2024-2032.

North America is likely to make noteworthy contributions towards overall Bearing Isolators Market revenue in the coming years.

The key players profiled in the report include Advanced Sealing International; Baldor Electric Company; The Timken Company; Isomag Corporation; Parker Hannifin Corporation; Inpro/Seal Designs; Elliott Group; AESSEAL; Garlock Sealing Technologies; The Flowserve Corporation; John Crane; and Beacon Gasket & Seals Co. Players in the industry are trying to introduce eco-friendly products as a part of their CSR imitative and this will further boost the market growth over the assessment year.

List of Contents

Market InsightsMarket:OverviewGrowth Dynamics1. Increased Industrial Automation2. Rising Demand for Reliability and Maintenance-free Operations3. Expansion in Heavy Industries4. Emphasis on Energy Efficiency5. Growth in Renewable Energy Sector6. Technological Advancements in Bearing Isolators7. Regulations and Environmental Standards8. Increased Focus on Predictive Maintenance9. Replacement and Retrofitting Demand10. Growing Industrialization in Emerging Markets11. Increased Focus on SustainabilityReport ScopeMarket:Regional InsightsNorth America To Gain Dominance In Global Market In Terms of Revenue By 2032Market:Competitive SpaceBy material type:By end-use industry:By RegionRelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed