Closed Molding Composites Market Size, Share, Market Trends, and Forecast, 2032

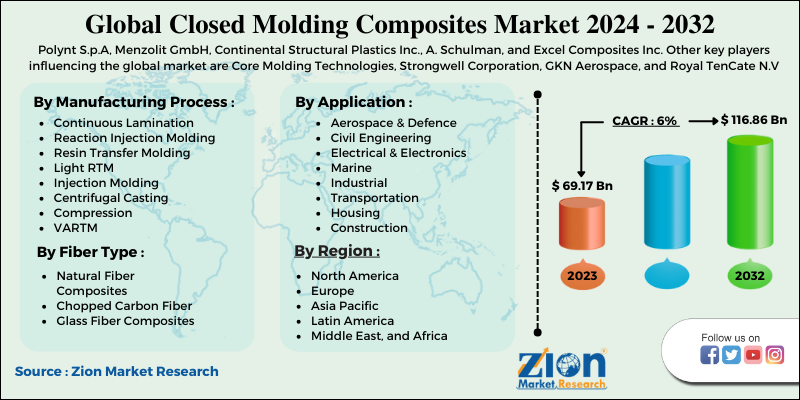

Closed Molding Composites Market By Manufacturing Process (Continuous Lamination, Reaction Injection Molding, Resin Transfer Molding (RTM), Vacuum Infusion & Bagging, Light RTM, Injection Molding, Centrifugal Casting, Compression, VARTM, and Others), By Fiber Type (Natural Fiber Composites, Chopped Carbon Fiber, Glass Fiber Composites, and Other Fiber Composites), By Application (Aerospace & Defence, Civil Engineering, Electrical & Electronics, Marine, Industrial, Transportation, Housing, Construction, Wind Energy, Sporting Goods and Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-

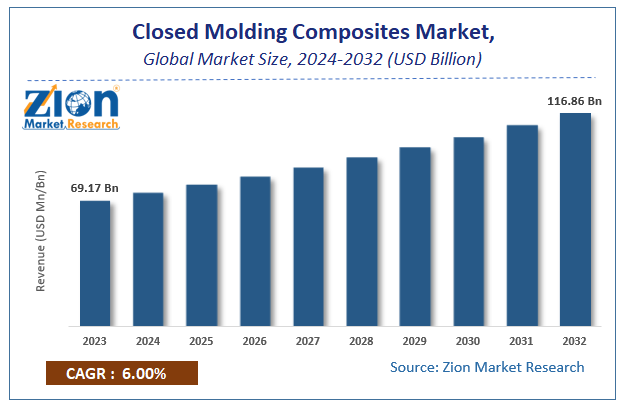

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 69.17 Billion | USD 116.86 Billion | 6% | 2023 |

Closed Molding Composites Market Insights

Zion Market Research has published a report on the global Closed Molding Composites Market, estimating its value at USD 69.17 Billion in 2023, with projections indicating that it will reach USD 116.86 Billion by 2032. The market is expected to expand at a compound annual growth rate (CAGR) of 6% over the forecast period 2024-2032.

The report explores the factors fueling market growth, the hitches that could hamper this expansion, and the opportunities that may arise in the Closed Molding Composites industry. Additionally, it offers a detailed analysis of how these elements will affect market demand dynamics and market performance throughout the forecast period.

Global Closed Molding Composites Market: Overview

Carbon fibers possess many properties such as the highest rigidity, electrical conductivity, high-temperature tolerance, temperature performance, high tensile strength, high chemical resistance, and lightweight as compared to other fibers. Owing to these properties, it is suitable for aerospace & defines applications. Carbon fibers are enough strong than traditional materials such as aluminum, iron, and steel. The most preferred process in the closed molding composites market is vacuum infusion & bagging owing to its environment-friendly nature rather than other closed molding processes.

Injection molding is another process that is widely used in electrical & electronics and transportation applications, mainly in the production of enclosures for medical devices, bumpers for vehicles, motor housings, enclosures for medical devices, panels for electrical equipment, and others.

Global Closed Molding Composites Market: Growth Factors

The growth factor of the global closed molding composites market includes an increase in the number of airplane deliveries and high-performance properties that comprise government regulations, lightweight, excellent safety, and acoustic features. Advanced closed molding composites enhance fatigue tolerance and that will improve the structure of components. However, some restrictions put by the government authorities on aerospace manufacturers using closed molding composites in the manufacturing of interior components of aircraft and primary & secondary structures.

Global Closed Molding Composites Market: Segmentation

The global closed molding composites market is bifurcated on the basis of the manufacturing process, fiber type, application, and geography.

The manufacturing processes include continuous lamination, reaction injection molding, resin transfer molding (RTM), vacuum infusion & bagging, light RTM, injection molding, centrifugal casting, compression, VARTM, and others.

The fiber segment is further sub-segmented as natural fiber composites, chopped carbon fiber, glass fiber composites, and other fiber composites including carbon fiber composites, aramid fiber composites, and continuous carbon fiber.

Furthermore, the application segment includes aerospace & defines, civil engineering, electrical & electronics, exteriors, marine, interiors, industrial, transportation, housing, construction, wind energy, sporting goods and others. Of these, aerospace & defines sector is the fastest growing segment, which contributed for the largest market share. These sectors need composite parts of high strength and which are lightweight. The closed molding composite reduces the weight of aircraft that enhances fuel the efficiency of airplanes.

Closed Molding Composites Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Closed Molding Composites Market |

| Market Size in 2023 | USD 69.17 Billion |

| Market Forecast in 2032 | USD 116.86 Billion |

| Growth Rate | CAGR of 6% |

| Number of Pages | 110 |

| Key Companies Covered | Polynt S.p.A, Menzolit GmbH, Continental Structural Plastics Inc., A. Schulman, and Excel Composites Inc. Other key players influencing the global market are Core Molding Technologies, Strongwell Corporation, GKN Aerospace, and Royal TenCate N.V |

| Segments Covered | By Manufacturing Process, By Fiber Type, By Application And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Closed Molding Composites Market: Regional Analysis

Asia Pacific is anticipated to experience enormous growth in terms of revenue in the global closed molding composites market in the next few years. Consumption of the closed molding composite in a number of industries such as construction, transportation, wind energy, electrical & electronics, and so on is expected to boost the global market in the near future. China contributed for the largest market share in the closed molding composites market owing to the increased consumption in this region in the aerospace & defines industries, sporting goods, and wind energy. The wind energy sector has exponentially grown in China and is anticipated to witness growth in the future.

Global Closed Molding Composites Market: Competitive Players

Key players in the global closed molding composites market are

- Polynt S.p.A

- Menzolit GmbH

- Continental Structural Plastics Inc

- A. Schulman

- Excel Composites Inc

- Core Molding Technologies

- Strongwell Corporation

- GKN Aerospace

- Royal TenCate N.V

global closed molding composites market is segmented as follows:

By Manufacturing Process

- Continuous Lamination

- Reaction Injection Molding

- Resin Transfer Molding (RTM)

- Vacuum Infusion & Bagging

- Light RTM

- Injection Molding

- Centrifugal Casting

- Compression

- VARTM

- Others

By Fiber Type

- Natural Fiber Composites

- Chopped Carbon Fiber

- Glass Fiber Composites

- Other Fiber Composites

By Application

- Aerospace & Defence

- Civil Engineering

- Electrical & Electronics

- Marine

- Industrial

- Transportation

- Housing

- Construction

- Wind Energy

- Sporting Goods

- Others

Closed Molding Composites Market: Regional Segment Analysis

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Closed moulding composites are the result of a manufacturing process in which composite materials are moulded in a closed cavity, typically between two mould surfaces. The purpose of this technique is to manufacture components with intricate shapes and superior surfaces. The closed moulding process is instrumental in the efficient and consistent production of composite parts by minimising waste and controlling the resin distribution.

Closed moulding composites are in high demand due to the necessity for lightweight, high-strength materials in sectors such as aerospace, automotive, and marine. These materials contribute to the enhancement of fuel efficiency and performance.

Zion Market Research has published a report on the global Closed Molding Composites Market, estimating its value at USD 69.17 Billion in 2023, with projections indicating that it will reach USD 116.86 Billion by 2032.

Zion Market Research has published a report on the global Closed Molding Composites Market is expected to expand at a compound annual growth rate (CAGR) of 6% over the forecast period 2024-2032.

Asia Pacific is anticipated to experience enormous growth in terms of revenue in the global closed molding composites market in the next few years. Consumption of the closed molding composite in a number of industries such as construction, transportation, wind energy, electrical & electronics, and so on is expected to boost the global market in the near future.

Key players in the global closed molding composites market are Polynt S.p.A, Menzolit GmbH, Continental Structural Plastics Inc., A. Schulman, and Excel Composites Inc. Other key players influencing the global market are Core Molding Technologies, Strongwell Corporation, GKN Aerospace, and Royal TenCate N.V.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed