Die Casting Market Size, Share, Analysis, Trends, Growth Report, 2032

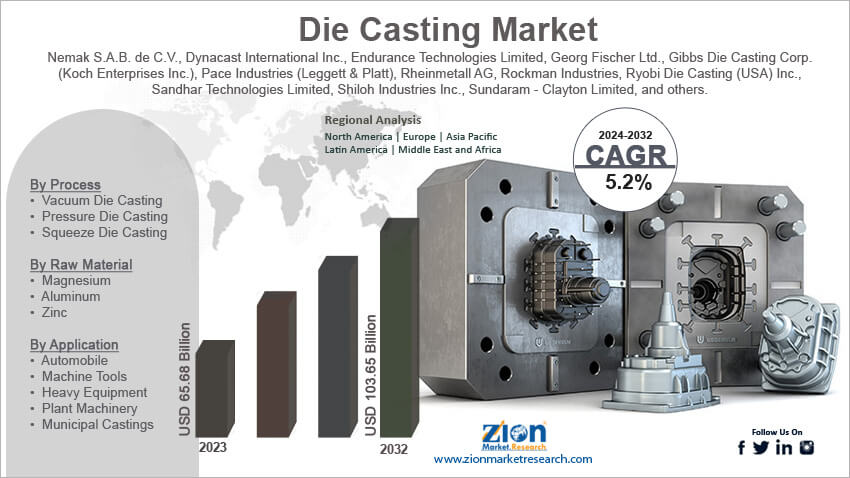

Die Casting Market By Process (Vacuum Die Casting, Pressure Die Casting, Squeeze Die Casting, and Others), By Raw Material (Magnesium, Aluminum, and Zinc), By Application (Automobile, Machine Tools, Heavy Equipment, Plant Machinery, Municipal Castings, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

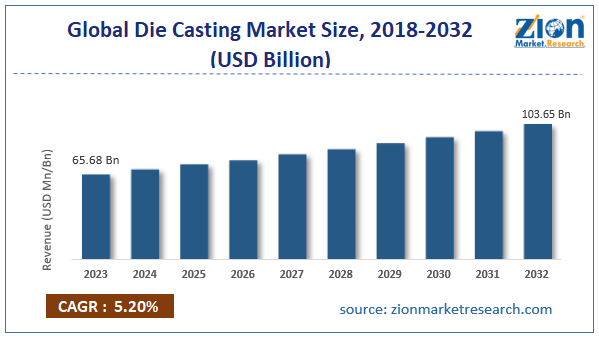

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 65.68 Billion | USD 103.65 Billion | 5.2% | 2023 |

Die Casting Industry Prospective:

The global die casting market size was worth around USD 65.68 billion in 2023 and is predicted to grow to around USD 103.65 billion by 2032 with a compound annual growth rate (CAGR) of roughly 5.2% between 2024 and 2032.

Die Casting Market: Overview

Die casting is the method of producing precise metal pieces by forcing molten metal into molds under intense pressure. Metals like lead, zinc, magnesium, aluminum, copper, and alloys based on tin are used in its manufacturing. It's commonly employed in the manufacturing of valves, decorative hardware, golf clubs, engine fans, toys, and connector housings. Die casting offers higher uniformity, lower production costs, and does away with assembly procedures in comparison to other manufacturing methods. Moreover, it offers a single mold design, increased production rate, decreased metal scrap, and improved precision. Die casting is widely used in the manufacturing, automotive, aerospace, defense, electronics, transportation, and building sectors.

Key Insights

- As per the analysis shared by our research analyst, the global die casting market is estimated to grow annually at a CAGR of around 5.2% over the forecast period (2024-2032).

- In terms of revenue, the global die casting market size was valued at around USD 65.68 billion in 2023 and is projected to reach USD 103.65 billion, by 2032.

- The growth in the automotive industry is expected to drive the global die casting market growth over the forecast period.

- Based on the process, the pressure die casting segment is expected to capture the largest market share over the projected period.

- Based on the raw material, the aluminum segment is expected to hold a prominent market share over the projected period.

- Based on the application, the automobile segment is expected to grow at the highest CAGR during the forecast period.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Request Free Sample

Request Free Sample

Die Casting Market: Growth Drivers

Growing use of aluminum in automotive drives market growth

Authorities are pushing automakers to improve car economy and reduce the negative effects of greenhouse gas emissions on the environment. Because aluminum lowers carbon dioxide (CO2), it is seen as a sustainable resource. It stops about 70 million tonnes of CO2 from entering the environment. Around 46 liters of fuel can be saved annually by using 100 kg of aluminum in automobiles. A few examples of aluminum die casting used in the automotive industry are engine blocks, suspension arms, frames, pistons, heat shields, trim, and heat exchangers. Vehicle weight can be significantly reduced because of the many uses for aluminum. The market share of aluminum die casting applications for automobiles is therefore anticipated to increase significantly. Thus, driving the die casting market growth over the forecast period.

Die Casting Market: Restraints

High capital requirement hinders market growth

The market for die casting is one of the heavy industries that generates massive machine tools, modest to large and heavy products, and other heavy equipment components. The industry also needs a large amount of space. For these reasons, heavy industries are acknowledged as being capital-intensive. Furthermore, it needs to be delivered by qualified staff, which drives up the total cost of die casting goods. A substantial investment in research and development (R&D) is required to produce high-quality products through ongoing technical advancements. The requirement for skilled workers to operate contemporary machinery, particularly in developing and underdeveloped nations, is another barrier to the die casting business.

Die Casting Market: Opportunities

Rising partnerships offer a lucrative opportunity for market growth

The increasing partnership is expected to offer a lucrative opportunity for die casting industry growth during the forecast period. For instance, in June 2023, Haitian Die Casting and Chongqing Millison Technologies Inc., a company with its headquarters located in Chongqing, China, and expertise in the design and production of solutions for the automotive and communication industries, signed a framework agreement for worldwide strategic cooperation. The foundation of the collaboration with Haitian Die Casting is a long-term shared development vision meant to advance and fortify international strategic initiatives. Technical advancement in the area of inventive ultra-large die casting production is another aspect of the collaboration. In this regard, the businesses declare that their collaborative initiative to build an HDC machine capable of 20,000 tons of clamping force has begun.

Die Casting Market: Challenges

Volatility in raw material prices poses a major challenge to market expansion

Changes in supply chains, market demand, and geopolitical issues can all affect the cost of raw materials used in die casting, including copper, zinc, magnesium, and aluminum. The profitability of die casting operations as well as overall production costs may be impacted by this instability. Thus, posing a major challenge to the die casting market growth.

Die Casting Market: Segmentation

The global die casting industry is segmented based on process, raw material, application, and region.

Based on the process, the global die casting market is bifurcated into vacuum die casting, pressure die casting, squeeze die casting, and others. The pressure die casting segment is expected to capture the largest market share over the projected period. A common and extremely effective manufacturing technique is pressure die casting, which involves injecting molten metal under high pressure into a mold cavity. Usually, this method is employed to create vast amounts of finely detailed, superior metal components. The requirement for lightweight, high-strength components created with pressure die casting is driven by the growing desire for lighter automobiles to increase fuel efficiency and lower emissions. Another important factor is the increase in EV production, which necessitates a large number of die-cast parts because of its lightweight and intricate components.

Based on the raw material, the global die casting industry is bifurcated into magnesium, aluminum, and zinc. The aluminum segment is expected to hold a prominent market share over the projected period. The consumer electronics, industrial machinery, automotive, and aerospace industries are anticipated to drive the market's robust revenue growth for aluminum die casting. Technological advancements, a focus on sustainability, and the opening up of new markets are all factors in this rise. Due to continuous innovation and shifting industry demands, the market has a promising future despite challenges such as high startup costs and volatile raw material prices.

Based on the application, the global die casting market is bifurcated into the automobile, machine tools, heavy equipment, plant machinery, municipal castings, and others. The automobile segment is expected to grow at the highest CAGR during the forecast period. Automakers are compelled by strict global pollution rules to decrease vehicle weight to improve fuel efficiency. To achieve these weight reductions without sacrificing strength and longevity, aluminum die casting is essential. In addition, car manufacturers are spending a lot of money on R&D to improve and reinvent die casting techniques, which is fueling the expansion of the industry.

Die Casting Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Die Casting Market |

| Market Size in 2023 | USD 65.68 Billion |

| Market Forecast in 2032 | USD 103.65 Billion |

| Growth Rate | CAGR of 5.20% |

| Number of Pages | 214 |

| Key Companies Covered | Nemak S.A.B. de C.V., Dynacast International Inc., Endurance Technologies Limited, Georg Fischer Ltd., Gibbs Die Casting Corp. (Koch Enterprises Inc.), Pace Industries (Leggett & Platt), Rheinmetall AG, Rockman Industries, Ryobi Die Casting (USA) Inc., Sandhar Technologies Limited, Shiloh Industries Inc., Sundaram - Clayton Limited, and others. |

| Segments Covered | By Process, By Raw Material, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Die Casting Market: Regional Analysis

Asia Pacific is expected to dominate the market during the forecast period

The Asia Pacific is expected to dominate the global die casting market during the forecast period. Die-casting is predicted to rise at a faster pace in the Asia-Pacific area because of the expanding vehicle industry, demand from the industrial sector, and expanded applications in windmills & telecommunications. Further acceleration of market growth in the Asia-Pacific region is anticipated due to lower labor costs and lower manufacturing prices in China and India. Moreover, manufacturers are focusing more on employing lightweight materials like aluminum to replace heavy steel and iron in all kinds of vehicles due to the growing demand for electric and hybrid vehicles. To create a single facility center for aluminum high-pressure die casting, for example, the Tamil Nadu Small Industries Development Corporation committed INR 5.8 crore in May 2022. Thus, the aforementioned facts drive the market growth in the region.

Die Casting Market: Competitive Analysis

The global die casting market is dominated by players like:

- Nemak S.A.B. de C.V.

- Dynacast International Inc.

- Endurance Technologies Limited

- Georg Fischer Ltd.

- Gibbs Die Casting Corp. (Koch Enterprises Inc.)

- Pace Industries (Leggett & Platt)

- Rheinmetall AG

- Rockman Industries

- Ryobi Die Casting (USA) Inc.

- Sandhar Technologies Limited

- Shiloh Industries Inc.

- Sundaram - Clayton Limited

The global die casting market is segmented as follows:

By Process

- Vacuum Die Casting

- Pressure Die Casting

- Squeeze Die Casting

- Others

By Raw Material

- Magnesium

- Aluminum

- Zinc

By Application

- Automobile

- Machine Tools

- Heavy Equipment

- Plant Machinery

- Municipal Castings

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Die casting is the method of producing precise metal pieces by forcing molten metal into molds under intense pressure. Metals like lead, zinc, magnesium, aluminum, copper, and alloys based on tin are used in its manufacturing. It's commonly employed in the manufacturing of valves, decorative hardware, golf clubs, engine fans, toys, and connector housings.

The market for die castings is being driven by several factors such as the growing automotive sector, technological advancements, rising government focus on light-weighting vehicles, and the increasing construction industry.

According to the report, the global die casting market size was worth around USD 65.68 billion in 2023 and is predicted to grow to around USD 103.65 billion by 2032.

The global die casting market is expected to grow at a CAGR of 5.2% during the forecast period.

The global die casting market growth is expected to be driven by the Asia Pacific. It is currently the world’s highest revenue-generating market due to the rising automotive sector.

The global die casting market is dominated by players like Nemak S.A.B. de C.V., Dynacast International Inc., Endurance Technologies Limited, Georg Fischer Ltd., Gibbs Die Casting Corp. (Koch Enterprises Inc.), Pace Industries (Leggett & Platt), Rheinmetall AG, Rockman Industries, Ryobi Die Casting (USA) Inc., Sandhar Technologies Limited, Shiloh Industries Inc. and Sundaram - Clayton Limited among others.

The die casting market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed