Digital Twins in Manufacturing Market Size, Share, Analysis, Trends, Growth, Forecasts, 2032

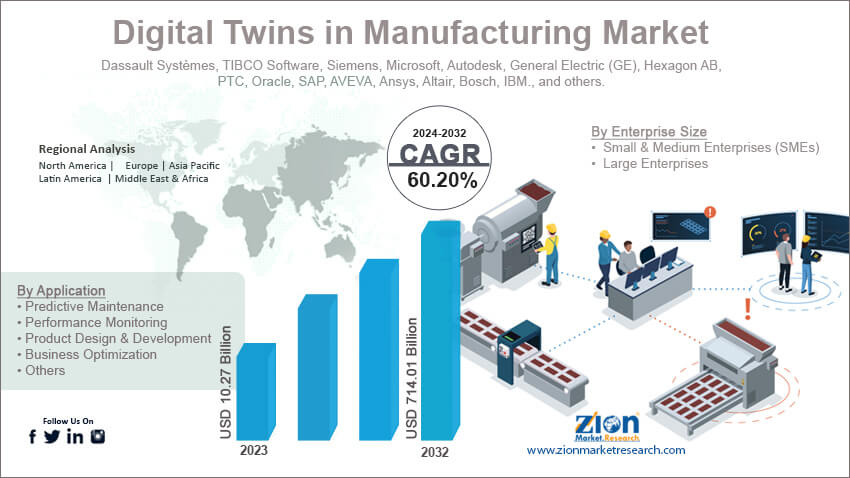

Digital Twins in Manufacturing Market By Enterprise Size (Small & Medium Enterprises (SMEs) and Large Enterprises), By Application (Predictive Maintenance, Performance Monitoring, Product Design & Development, Business Optimization, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-

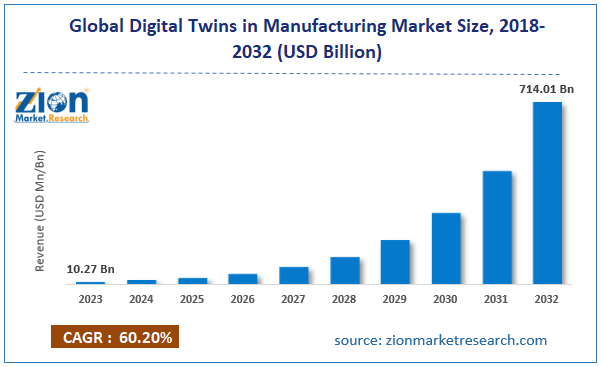

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 10.27 Billion | USD 714.01 Billion | 60.20% | 2023 |

Digital Twins in Manufacturing Industry Prospective:

The global digital twins in manufacturing market size was worth around USD 10.27 billion in 2023 and is predicted to grow to around USD 714.01 billion by 2032 with a compound annual growth rate (CAGR) of roughly 60.20% between 2024 and 2032.

Digital Twins in Manufacturing Market: Overview

A digital twin is defined as an electronic or digital replica of a system, process, or physical asset. Digital twins in manufacturing are used to enhance and improve applications to meet business objectives. The manufacturing industry has been a front-runner in terms of accepting digital twin technology to make business processes more effective.

For instance, digital twins in manufacturing are mainly built for specific production lines, assets, or final products. Other real-world scenarios can also be replicated using digital twins technology. The current manufacturing industry has been rapidly evolving due to the changing consumer demands. In addition to this, the number of initial reprices used for building a product has increased over the years. Effective management of key resources is an important aspect of business operations.

Digital twin technology delivers a highly dynamic replica of the real-world scenario. The technology is designed to not only capture or map process variables but also provide a better structure. The demand for digital twins in manufacturing has been growing rapidly, driven by increased applications across end-users. However, the high cost of the technology could inhibit the digital twins in manufacturing industry growth rate.

Key Insights:

- As per the analysis shared by our research analyst, the global digital twins in manufacturing market are estimated to grow annually at a CAGR of around 60.20% over the forecast period (2024-2032)

- In terms of revenue, the global digital twins in manufacturing market size was valued at around USD 10.27 billion in 2023 and is projected to reach USD 714.01 billion, by 2032.

- The digital twins in manufacturing market is projected to grow at a significant rate due to the growing focus on predictive maintenance across manufacturing facilities.

- Based on enterprise size, the large enterprise segment is growing at a high rate and will continue to dominate the global market as per industry projections.

- Based on the application, the product design & development segment is anticipated to command the largest market share.

- Based on region, Europe is projected to dominate the global market during the forecast period.

Request Free Sample

Request Free Sample

Digital Twins in Manufacturing Market: Growth Drivers

Growing focus on predictive maintenance across manufacturing facilities will drive the market demand rate

The global digital twins in manufacturing market are expected to grow due to the rising importance of predictive maintenance across production facilities. According to market research, predictive maintenance is defined as a novel strategy that leverages data to detect and schedule maintenance of equipment before the occurrence of any failure. Predictive maintenance (PdM) relies heavily on data analysis procedures for the identification of mild or severe performance anomalies as well as defects in equipment.

The strategy ensures timely repairs, thus reducing machine or process downtime and saving businesses from incurring significant losses. Predictive maintenance has become integral to new business strategies since it ensures continuous product manufacturing without any delay or glitch. Digital twins in manufacturing are regularly used for predictive maintenance procedures. The technology is used for creating the exact digital copy of a physical asset that can be monitored from all angles at all times.

Such in-depth and perpetual monitoring of physical machines is practically impossible. Hence, digital twins in production procedures are helpful in predicting if a specific machine part requires replacement or further maintenance. The global predictive maintenance industry is expected to cross more than USD 100 billion in revenue during the forecast period.

Higher demand for digital twins in medical manufacturing will be essential to the industry’s expansion rate

The demand for digital twins during the manufacturing of healthcare products such as medical equipment, accessories, and medicines is growing significantly. The trend is influenced by the increasing pressure on the healthcare and pharmaceutical industry to deliver products of superior quality. In recent times, incidents related to commercial sales of substandard medical products have encouraged more end-users to incorporate digital twins technology.

For instance, in August 2024, major drug makers Glenmark, Aurobindo Pharma, and Fairdeal Corporation Limited (FDC) recalled products from the US market due to defects in the manufacturing process. The global digital twins in manufacturing market players can generate more revenue by investing in the medical and pharmaceutical manufacturing sector.

Digital Twins in Manufacturing Market: Restraints

Significant costs involved with the implementation of digital twins will limit the market’s expansion rate

The global industry for digital twins in manufacturing is expected to be restricted due to the high cost of implementing the technology. As per market studies, the average cost of developing a digital twin platform can reach over USD 60,000, depending on the features incorporated in the tool.

Additionally, the overall cost increases further with the addition of implementation and training-related expenses. The changing order in the global economy could impact the industry’s growth rate in the future.

Digital Twins in Manufacturing Market: Opportunities

Increasing use of the technology in the growing automotive industry is likely to generate growth opportunities

The global digital twins in manufacturing market are expected to generate growth opportunities due to higher demand in the automotive industry. The introduction and growing demand for electric vehicles (EVs) and the demand for novel engineering solutions will fuel the adoption of digital twin systems during the production and designing of new vehicles. The EV sector is expected to reshape the global automotive industry in the future.

Electric vehicles are significantly different from traditionally used internal combustion engine-powered vehicles. Moreover, the use of digital twins in the production of luxury cars, including sports vehicles, will provide the necessary push for the industry to grow.

Integration of Machine Learning (ML) and Artificial Intelligence (AI) with digital twins will be fruitful

Digital twins technology is steadily evolving. The integration of advanced systems such as AI and ML with digital twin technology is expected to drive more revenue in the industry. These technologies along with other cutting-edge solutions such as big data and real-time data integration will improve the final output delivered by the solutions.

Moreover, the incorporation of virtual reality (VR) and augmented reality (AR) can assist in creating an immersive user experience, thus benefiting the global digital twins in the manufacturing industry.

Digital Twins in Manufacturing Market: Challenges

Risk of digital security breach could challenge market expansion trends

The sector for digital twins in manufacturing is projected to be challenged by the growing risk of security breaches. Digital twin systems in manufacturing industry have access to real-time information about business processes and assets. The technology is vulnerable to cyber-attacks and other forms of digital crimes.

Digital Twins in Manufacturing Market: Segmentation

The global digital twins in the manufacturing market are segmented based on enterprise size, application, and region.

Based on the enterprise size, the global market segments are small & medium enterprises (SMEs) and large enterprises. In 2023, the highest growth was observed in the large enterprises segment. Industries with massive production lines have the required budget to fund the deployment of digital twin technology.

Moreover, the massive manufacturing lines in large-scale businesses are most optimally monitored using automated systems driving segmental revenue. Companies tend to spend nearly 15 to 20% of sales revenue on quality management solutions.

Based on the application, the digital twins in manufacturing industry divisions are predictive maintenance, performance monitoring, product design & development, business optimization, and others. In 2023, the highest growth was registered in the product design & development segment.

Digital twins during product development are essential to manage anomalies before production begins. Companies can save considerable costs by detecting product defaults in the initial stages. The real-world accuracy rate of digital twins can range between 71 to 90%.

Digital Twins in Manufacturing Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Digital Twins in Manufacturing Market |

| Market Size in 2023 | USD 10.27 Billion |

| Market Forecast in 2032 | USD 714.01 Billion |

| Growth Rate | CAGR of 60.20% |

| Number of Pages | 229 |

| Key Companies Covered | Dassault Systèmes, TIBCO Software, Siemens, Microsoft, Autodesk, General Electric (GE), Hexagon AB, PTC, Oracle, SAP, AVEVA, Ansys, Altair, Bosch, IBM., and others. |

| Segments Covered | By Enterprise Size, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Digital Twins in Manufacturing Market: Regional Analysis

Europe to deliver exceptional results during the forecast period

The global digital twins in manufacturing market will be led by Europe during the projection period. The regional demand is led by higher use of digital twin systems for designing and producing superior-grade automotives. Luxury car makers such as BMW and others are already using the technology to develop state-of-the-art vehicles for their global customers.

Additionally, the increasing investments in the construction of new large-scale production sites spread across acres of land and utilizing key resources will create growth opportunities for digital twin technology in Europe.

In a recent event, Mercedes-Benz Cars announced the construction of its first Full-Flex Plant based in Hungary. Similarly, the demand for electric vehicles across European countries has increased rapidly, leading to market players opting for measures that promote innovation. The regional demand will also be fueled by the shifting focus toward improving energy efficiency across industrial sites.

North America is projected to grow due to ongoing investments in the development and further enhancement of digital twins technology. The US is betting big on investments for domestic production of semiconductors. It could create novel expansion possibilities for the regional market players since semiconductor fabrication is a complex process requiring high inputs from advanced digital solutions.

Digital Twins in Manufacturing Market: Competitive Analysis

The global digital twins in manufacturing market is led by players like:

- Dassault Systèmes

- TIBCO Software

- Siemens

- Microsoft

- Autodesk

- General Electric (GE)

- Hexagon AB

- PTC

- Oracle

- SAP

- AVEVA

- Ansys

- Altair

- Bosch

- IBM.

The global digital twins in manufacturing market is segmented as follows:

By Enterprise Size

- Small & Medium Enterprises (SMEs)

- Large Enterprises

By Application

- Predictive Maintenance

- Performance Monitoring

- Product Design & Development

- Business Optimization

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A digital twin is defined as an electronic or digital replica of a system, process, or physical asset.

The global digital twins in manufacturing market are expected to grow due to the rising importance of predictive maintenance across production facilities.

According to study, the global digital twins in manufacturing market size was worth around USD 10.27 billion in 2023 and is predicted to grow to around USD 714.01 billion by 2032.

The CAGR value of digital twins in manufacturing market is expected to be around 60.20% during 2024-2032.

The global digital twins in the manufacturing market will be led by Europe during the projection period.

The global digital twins in manufacturing market is led by players like Dassault Systèmes, TIBCO Software, Siemens, Microsoft, Autodesk, General Electric (GE), Hexagon AB, PTC, Oracle, SAP, AVEVA, Ansys, Altair, Bosch and IBM.

The report explores crucial aspects of the digital twins in manufacturing market including a detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed