Global Extrusion Coating Market Size, Share, Analysis, Trends, Growth, 2034

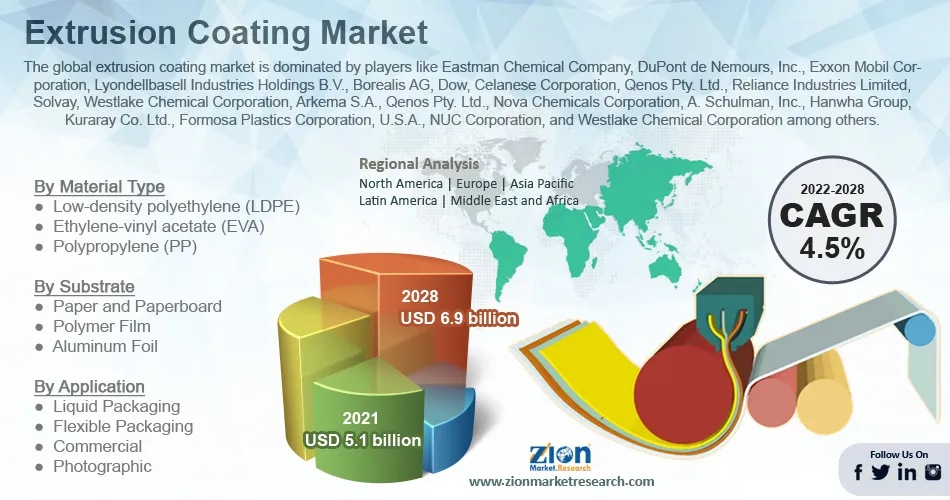

Extrusion Coating Market By Material Type (Low-density polyethylene (LDPE), Ethylene-vinyl Acetate (EVA), and Polypropylene (PP)), By Substrate (Paper and Paperboard, Polymer Film, and Aluminum Foil), By Application (Liquid Packaging, Flexible Packaging, Commercial, and Photographic), And By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

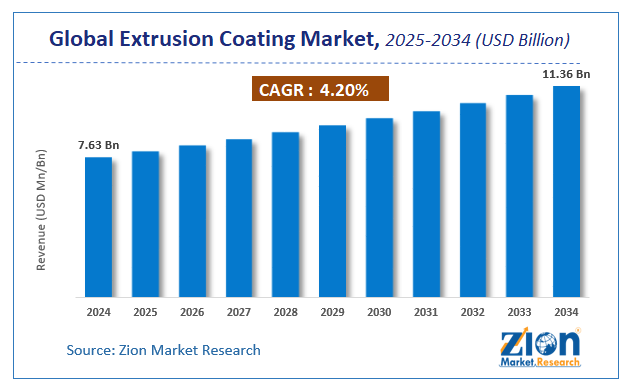

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 7.63 Billion | USD 11.36 Billion | 4.2% | 2024 |

Extrusion Coating Industry Prospective:

The global extrusion coating market size was worth around USD 7.63 Billion in 2024 and is predicted to grow to around USD 11.36 Billion by 2034 with a compound annual growth rate (CAGR) of roughly 4.2% between 2025 and 2034. The report analyzes the global extrusion coating market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the extrusion coating market.

Extrusion Coating Market: Overview

Extrusion coatings are applied to substrates like cellulose, paper, paperboard, aluminum foils, corrugated fiberboard, and plastic films. They are made of a molten web of synthetic resin. The actual extrusion coating procedure involves the direct, up to 320°C, extrusion of resin from a slot die. The product may then be put through a nip that has a cooling roll that is chrome-plated and has a rubber covering.

The market for extrusion coatings has provided cutting-edge technology for packaging methods in numerous end-user industries to safeguard finished goods against moisture, rain, dust, temperature changes, cracks, etc. Extrusion coatings are predicted to outperform aseptic flexible bricks and are also utilized in tubes for personal care and cosmetic products, as well as pillow-like compact pouches for disposables and medications, vacuum packaging for pet food and coffee, and other applications. A few polymers are employed in extrusion coating, with low-density polyethylene (LDPE), ethylene-vinyl acetate (EVA), polypropylene, and polyethylene terephthalate as the most popular due to their attracting properties.

Key Insights

- As per the analysis shared by our research analyst, the global extrusion coating market is estimated to grow annually at a CAGR of around 4.2% over the forecast period (2025-2034).

- Regarding revenue, the global extrusion coating market size was valued at around USD 7.63 Billion in 2024 and is projected to reach USD 11.36 Billion by 2034.

- The extrusion coating market is projected to grow at a significant rate due to rising demand in packaging, construction, and automotive industries due to barrier properties, flexibility, and sustainability trends.

- Based on Material Type, the Low-density polyethylene (LDPE) segment is expected to lead the global market.

- On the basis of Substrate, the Paper and Paperboard segment is growing at a high rate and will continue to dominate the global market.

- Based on the Application, the Liquid Packaging segment is projected to swipe the largest market share.

- Based on region, Asia-Pacific is predicted to dominate the global market during the forecast period.

To know more about this report, request a sample copy.

Extrusion Coating Market: Growth Drivers

Increasing demand for extrusion coating from the food & beverage industry to drive the market growth

The food and beverage business has experienced significant expansion recently, primarily as a result of population growth, rising disposable income, and a rise in public awareness of health issues. Growing public health concerns are driving demand for low-calorie, sugar-free, gluten-free, and lactose-free food products.

Extrusion coating materials play a significant part in packaging applications for the food and beverage industry since they protect products from outside environmental impacts and give them a pleasing appearance, both of which are anticipated to spur the global extrusion coating market growth in the following years. Another advantage that drives businesses in the food and beverage industry to choose PP for product packaging is that it is recyclable. Therefore, the dominant trend in the market for extrusion coating is the growing usage of PP in food and beverage packaging.

Extrusion Coating Market: Restraints

Carbon footprint contribution is expected to hamper market expansion

Low and high melting temperatures, an air gap that is either too small or too large, and an inadequate resin selection can frequently result in improper adhesion between the substrate and the plastic sheet, which can, in turn, limit the growth of the market for extrusion coatings throughout the forecast period. Additionally, problems like edge tears, surging, sealability, pinholes, gels, and voids brought on by improper die designs, incorrect deckle settings, corrosion, low coating weight, excessive corona treatment, and others could restrain the expansion of the extrusion coatings market throughout the forecast period.

Extrusion Coating Market: Opportunities

The development of bio-based polymer as a raw material is expected to provide a lucrative opportunity for the market growth

The development of bio-based polymer as a raw material is expected to provide a lucrative opportunity for the global extrusion coating market growth during the forecast period. Packaging materials that are bio-based and biodegradable are receiving more global attention.

Growing environmental awareness, waste management & landfilling, resource scarcity, the deposition of plastic in the ocean, waste legislation, producer & consumer accountability, the need to reduce energy consumption, and marketing trends are some of the factors pushing manufacturers to develop more sustainable packaging materials.

The use of bio-based polymers, as opposed to those made from fossil carbon, actually represents a solution that can successfully address the aforementioned demands, mainly because of their sustainability, biodegradability, biocompatibility, availability, and non-toxicity. In addition, they result in a potential decrease in the overall carbon footprint. Thus, the aforementioned facts are expected to provide a lucrative opportunity for market growth.

Extrusion Coating Market: Segmentation

The global extrusion coating market is segmented based on the material type, substrate, application, and region

Based on material type, the global market is bifurcated into Low-density polyethylene (LDPE), Ethylene-vinyl acetate (EVA), and Polypropylene (PP). The Low-density polyethylene (LDPE) segment is expected to dominate the market during the forecast period. This material, which is employed in folding carton/cup stocks, liquid packaging, snack food lamination, and sealing layers, is easily able to tolerate temperatures of up to 80 degrees Celsius for a long period. Due to its remarkable characteristics, including a strong moisture barrier and salability attributes, LDPE is very significant and is employed in a variety of applications, including liquid packaging and flexible packaging.

The market for extrusion coating is anticipated to be driven in the future by the expanding use of LDPE in numerous end-use sectors, including packaging, automotive, design & design, medical & pharmaceutical, and others. Besides, the Polypropylene (PP) segment is expected to grow at the highest CAGR over the forecast period owing to its properties such as tough, rigid, and crystalline thermoplastics. Additionally, Polypropylene (PP) is one of the most commonly used thermoplastics in the world. Polypropylene uses range from plastic packaging, plastic parts for machinery and equipment, and even fibers and textiles. Thus, driving segmental growth.

Based on substrate, the market is segmented into paper and paperboard, polymer film, and aluminum foil. The paper and paperboard segment holds the largest market share in 2021 and is expected to show its dominance during the forecast period. Paper is used to package a variety of foods, including snacks, veggies, and other foods, due to the superior qualities of paperboard, such as lightweight, recyclability, affordability, and environmental friendliness. Moreover, government initiatives in several countries to restrict the use of plastic for packaging purposes will also contribute significantly to the segment's growth.

Based on application, the global extrusion coating market is segmented into liquid packaging, flexible packaging, commercial, and photographic. Liquid packaging is expected to dominate the market during the forecast period. This is because extrusion coating materials are used in liquid packaging to increase the commercial viability of several categories of liquid and semi-solid food products, like milk, juice, and sauce. Additionally, it is projected that the continued expansion of the personal care and cosmetics industries will lead to a rise in the usage of liquid packaging and, consequently, extrusion coatings. Liquid wrapping is one application utilized for both short- and long-shelf-life items. Liquid packaging experienced the greatest market growth as a result of its widespread application in the food packaging sector.

Recent Developments:

- In March 2022, Allnex, a leading supplier of resins for sustainable coatings solutions, announces the acquisition of the Mahad Manufacturing site and coating resins business from D.R. Coats Ink & Resins Pvt. Ltd. (DRC), located in Maharashtra, India. This strategic acquisition will foster close collaboration with local and regional customers, suppliers, and technology partners and help develop several attractive business opportunities.

- In January 2022, WL Plastics Corporation announced it has completed the acquisition of the polyethylene pipe extrusion assets of Charter Plastics, located in Titusville, Pennsylvania. This strategic acquisition provides the opportunity for WL Plastics to further diversify its product offerings, expand its customer base, and enter new regional markets.

Extrusion Coating Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Extrusion Coating Market |

| Market Size in 2024 | USD 7.63 Billion |

| Market Forecast in 2034 | USD 11.36 Billion |

| Growth Rate | CAGR of 4.2% |

| Number of Pages | 192 |

| Key Companies Covered | like Eastman Chemical Company, DuPont de Nemours Inc., Exxon Mobil Corporation, Lyondellbasell Industries Holdings B.V., Borealis AG, Dow, Celanese Corporation, Qenos Pty. Ltd., Reliance Industries Limited, Solvay, Westlake Chemical Corporation, Arkema S., and others. |

| Segments Covered | By Material Type, By Substrate, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, The Middle East and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2020 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Extrusion Coating Market: Regional Analysis

The Asia Pacific region is expected to dominate the market during the forecast period

The Asia Pacific region is expected to dominate the global extrusion coating market during the forecast period due to China's high levels of consumption, as well as forthcoming projects, and demand from India, ASEAN nations, and others for extrusion coating products. The expansion of the packaging sector, the size of the consumer market, and the rising need for more efficient products are all factors contributing to the region's growth. On the other hand, North America is expected to capture significant market share owing to the increase in ready-to-consume meals and ready-to-drink beverages, and the growth of the healthcare industries.

Extrusion Coating Market: Competitive Analysis

The report provides a company market share analysis to give a broader overview of the key market players. In addition, the report also covers key strategic developments of the market, including acquisitions & mergers, new product launches, agreements, partnerships, collaborations & joint ventures, research & development, and regional expansion of major participants involved in the extrusion coating market on a global and regional basis.

The global extrusion coating market is dominated by players like

- Eastman Chemical Company

- DuPont de Nemours. Inc.

- Exxon Mobil Corporation

- Lyondellbasell Industries Holdings B.V.

- Borealis AG

- Dow

- Celanese Corporation

- Qenos Pty. Ltd.

- Reliance Industries Limited

- Solvay

- Westlake Chemical Corporation

- Arkema S.A.

- Qenos Pty. Ltd.

- Nova Chemicals Corporation

- A. Schulman. Inc.

- Hanwha Group

- Kuraray Co. Ltd.

- Formosa Plastics Corporation

- U.S.A.

- NUC Corporation

- Westlake Chemical Corporation

- among others.

The global extrusion coating market is segmented as follows:

By Material Type

- Low-density polyethylene (LDPE)

- Ethylene-vinyl acetate (EVA)

- Polypropylene (PP)

By Substrate

- Paper and Paperboard

- Polymer Film

- Aluminum Foil

By Application

- Liquid Packaging

- Flexible Packaging

- Commercial

- Photographic

By Region

- North America

- The U.S.

- Canada

- Mexico

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- Australia

- South Korea

- Rest of Asia Pacific

- The Middle East & Africa

- Saudi Arabia

- UAE

- Egypt

- Kuwait

- South Africa

- Rest of the Middle East & Africa

- Latin America

- Brazil

- Argentina

- Rest of Latin America

Table Of Content

Methodology

FrequentlyAsked Questions

The global extrusion coating market cap may grow owing to the use & application of extrusion-coated paperboard enhances consumer handling, visual appeal, and heat sealability. Moreover, the growing demand from the food & beverages industries drives the market growth.

The global extrusion coating market is expected to grow due to rising demand for flexible and protective packaging in food, pharmaceutical, and industrial applications.

According to a study, the global extrusion coating market size was worth around USD 7.63 Billion in 2024 and is expected to reach USD 11.36 Billion by 2034.

The global extrusion coating market is expected to grow at a CAGR of 4.2% during the forecast period.

Asia-Pacific is expected to dominate the extrusion coating market over the forecast period.

Leading players in the global extrusion coating market include like Eastman Chemical Company, DuPont de Nemours Inc., Exxon Mobil Corporation, Lyondellbasell Industries Holdings B.V., Borealis AG, Dow, Celanese Corporation, Qenos Pty. Ltd., Reliance Industries Limited, Solvay, Westlake Chemical Corporation, Arkema S., among others.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed