Feed Water Heater for Power Plants Market Size, Share, Analysis, Trends, Growth Report, Forecasts 2023 - 2030

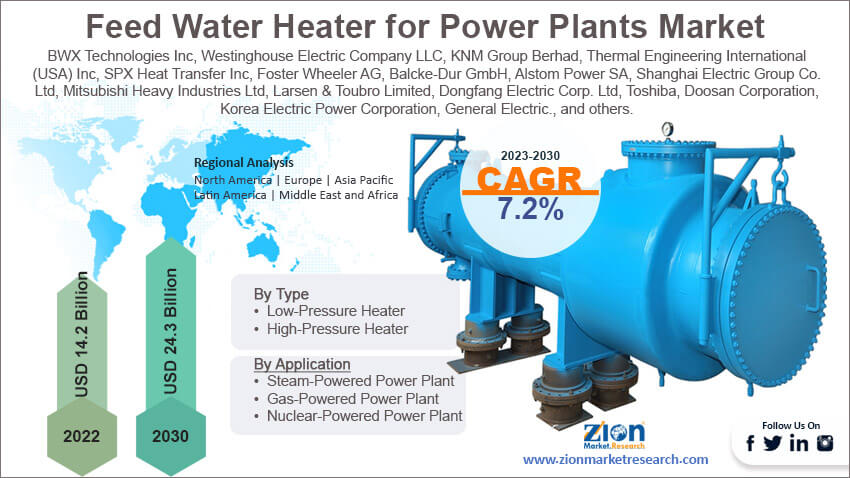

Feed Water Heater for Power Plants Market by Type (Low-Pressure Heater and High-Pressure Heater) and By Application (Steam-Powered Power Plant, Gas-Powered Power Plant and, Nuclear-Powered Power Plant), By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

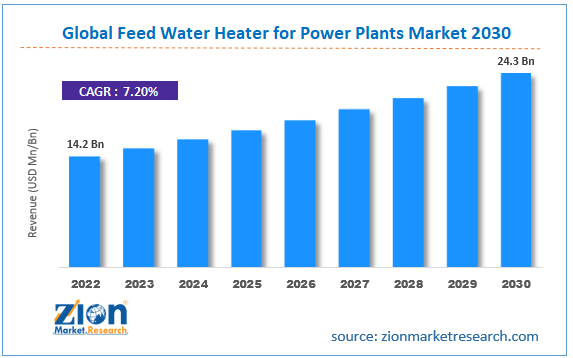

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 14.2 Billion | USD 24.3 Billion | 7.2% | 2022 |

Feed Water Heater for Power Plants Industry Prospective:

The global feed water heater for power plants market size was worth around USD 14.2 billion in 2022 and is predicted to grow to around USD 24.3 billion by 2030 with a compound annual growth rate (CAGR) of roughly 7.2% between 2023 and 2030.

Feed Water Heater for Power Plants Market: Overview

Feedwater heaters are crucial components in power plants that improve thermal efficiency by pre-heating water before it enters the boiler. This process reduces the amount of fuel needed to generate steam, resulting in significant energy savings and lower operational costs. By utilizing waste heat from the power generation process, feedwater heaters contribute to a more sustainable and environmentally friendly operation. There are two main types of feedwater heaters: open-type and closed-type. Open-type heaters allow direct contact between the feedwater and steam, while closed-type heaters keep them separate, using a series of tubes or plates for heat exchange.

Closed-type heaters are commonly used in high-pressure applications to prevent contamination. Feedwater heaters find widespread application in various power plants, including steam-powered, gas-powered, and nuclear-powered facilities. In steam-powered plants, they are integral to the Rankine cycle, enhancing overall energy conversion efficiency. In gas-powered plants, they play a crucial role in combined-cycle systems, recovering waste heat from the gas turbine exhaust. In nuclear-powered plants, feedwater heaters aid in the conversion of nuclear energy to steam for electricity generation. Overall, feedwater heaters significantly contribute to the overall performance and efficiency of power plants, making them indispensable components in the global energy landscape. Their continued development and integration in power generation facilities contribute to more sustainable and economically viable electricity production.

Key Insights

- As per the analysis shared by our research analyst, the global feed water heater for power plants industry is estimated to grow annually at a CAGR of around 7.2% over the forecast period (2023-2030).

- In terms of revenue, the global feed water heater for power plants market size was valued at around USD 14.2 billion in 2022 and is projected to reach USD 24.3 billion, by 2030.

- The global feed water heater for power plants market is projected to grow at a significant rate due to the increasing demand for electricity worldwide, driven by industrialization and urbanization.

- Based on type segmentation, low-pressure heater was predicted to hold maximum market share in the year 2022.

- Based on application segmentation, steam-powered power plant were the leading revenue generator in 2022.

- On the basis of region, Asia Pacific was the leading revenue generator in 2022.

Request Free Sample

Request Free Sample

Feed Water Heater for Power Plants Market: Growth Drivers

Increasing demand for electricity worldwide, driven by industrialization and urbanization is advancing growth of the market.

The global feed water heater market for power plants is experiencing robust growth, primarily propelled by the surging demand for electricity on a global scale. This escalation is chiefly attributed to the rapid pace of industrialization and urbanization across various regions. As industries expand and urban centers burgeon, the need for reliable and efficient power generation becomes paramount. Feed water heaters play a pivotal role in this landscape by optimizing the thermal efficiency of power plants. By pre-heating water before it enters the boiler, they reduce the energy required to generate steam, resulting in substantial operational cost savings.

Furthermore, the increasing focus on sustainable and eco-friendly energy solutions is driving investments in technologies that enhance the performance of power plants. Feed water heaters align perfectly with this objective, as they contribute significantly to energy efficiency. By harnessing waste heat from the power generation process, they not only enhance the overall sustainability of power plants but also aid in minimizing greenhouse gas emissions. This dual benefit positions feed water heaters as essential components in the global pursuit of more environmentally responsible power generation methods. As a result, the market for feed water heaters is projected to witness sustained growth as industries and nations continue their transition toward more sustainable and efficient energy production.

Feed Water Heater for Power Plants Market: Restraints

High initial capital investment required for the procurement and installation may restrain the market growth.

The significant barrier to entry in the feed water heater industry for power plants lies in the substantial initial capital investment needed to acquire and install advanced feed water heating systems. These sophisticated technologies are integral for optimizing thermal efficiency in power plants. However, their upfront cost can be a significant deterrent for power plant operators, especially for smaller or financially constrained organizations. The procurement and implementation of efficient feed water heaters entail a substantial financial outlay, which may pose a challenge for operators seeking to balance their budgets while striving for improved operational efficiency.

This financial consideration can lead to hesitations or delays in adopting these technologies, potentially hampering the overall growth and adoption of advanced feed water heating systems. Moreover, the extended period required to realize a return on investment (ROI) for feed water heaters can further exacerbate the challenge. While these systems offer long-term operational cost savings through improved energy efficiency, the time it takes to recoup the initial capital expenditure may be a deterrent for some operators. This dynamic necessitates careful financial planning and strategic decision-making to ensure that the benefits of enhanced thermal efficiency outweigh the initial investment costs. Finding innovative financing solutions and exploring opportunities for cost-effective system deployment are crucial steps towards mitigating this restraint and facilitating the broader adoption of advanced feed water heating systems in the power generation industry.

Feed Water Heater for Power Plants Market: Opportunities

Development and adoption of advanced materials and technologies to provide growth opportunities

The development and adoption of advanced materials and technologies present a substantial growth opportunity in the global feed water heater market for power plants. Continuous research and innovation in materials science have led to the creation of corrosion-resistant alloys and high-performance coatings. These breakthroughs hold the potential to significantly enhance the durability and efficiency of feed water heaters. By incorporating these advanced materials, manufacturers can produce feed water heaters with longer operational lifespans, reduced maintenance requirements, and improved overall performance.

This not only translates to cost savings for power plant operators but also contributes to a more sustainable and reliable energy generation process. Furthermore, the integration of smart and IoT-enabled technologies represents another promising avenue for growth. These technologies allow for real-time monitoring and data-driven decision-making in feed water heater operations. By leveraging sensors, data analytics, and connectivity solutions, power plant operators can gain valuable insights into the performance and condition of their feed water heaters. This facilitates predictive maintenance strategies, enabling operators to address potential issues before they escalate into costly disruptions. The adoption of advanced materials and technologies, coupled with the integration of smart solutions, not only drives efficiency and reliability but also positions companies at the forefront of innovation in the competitive feed water heater market.

Feed Water Heater for Power Plants Market: Challenges

Need for continuous research and development to stay ahead of evolving industry standards may challenge market growth

The feed water heater market for power plants faces a formidable challenge in the imperative for ongoing research and development. With industry standards and technological landscapes evolving at a rapid pace, manufacturers must remain at the cutting edge to remain competitive and meet the dynamic demands of the antimicrobial powder coatings industry. This necessitates a sustained commitment to innovation, requiring substantial investments in R&D initiatives. Manufacturers must constantly explore advanced materials, coatings, and technologies that can enhance the efficiency, durability, and performance of feed water heaters.

Additionally, staying ahead of emerging environmental and regulatory requirements is crucial. Adapting to evolving standards while simultaneously striving for optimal thermal efficiency poses a complex task that demands agility and a deep understanding of the evolving landscape of power generation. Overcoming this challenge requires a strategic approach, strong collaboration between research teams and engineering departments, and a keen awareness of market trends. Companies that prioritize continuous innovation and invest in robust R&D infrastructure will be better positioned to navigate the complexities of the evolving industry landscape. They will not only meet current industry standards but will also be prepared to lead in the development of next-generation feed water heating solutions, driving market growth and ensuring their competitive edge in the dynamic power generation sector.

Feed Water Heater for Power Plants Market: Segmentation

The global feed water heater for power plants market is segmented based on type, application, and region.

Based on type, the global market segments are low-pressure heater and high-pressure heater at present, the global market is dominated by the low-pressure heater segment. This large market share is attributed to its widespread application in various industries and processes. Low-pressure heaters play a crucial role in power generation and industrial applications by efficiently pre-heating feedwater before it enters the boiler, thereby optimizing thermal efficiency. This leads to significant energy savings and operational cost reductions. Additionally, low-pressure heaters are typically more common in power plants and industrial facilities, where they are utilized extensively to enhance overall system performance. Their versatility and cost-effectiveness have solidified their position as the leading segment in the market, as industries prioritize efficient energy utilization and cost-effective operations.

Based on application the global feed water heater for power plants market is categorized as steam-powered power plant, gas-powered power plant, and nuclear-powered power plant. Out of these steam-powered power plant was the largest shareholding segment in the global market. This is primarily due to the widespread use of steam-powered plants in electricity generation, making feedwater heaters a critical component for optimizing thermal efficiency. These heaters play a vital role in pre-heating water before it enters the boiler, thereby improving overall energy efficiency and reducing operational costs. The dominance of the steam-powered power plant segment underscores the significance of feedwater heaters in the power generation industry, particularly in steam-driven facilities where efficient energy utilization is paramount.

Feed Water Heater for Power Plants Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Feed Water Heater for Power Plants Market |

| Market Size in 2022 | USD 14.2 Billion |

| Market Forecast in 2030 | USD 24.3 Billion |

| Growth Rate | CAGR of 7.2% |

| Number of Pages | 219 |

| Key Companies Covered | BWX Technologies Inc, Westinghouse Electric Company LLC, KNM Group Berhad, Thermal Engineering International (USA) Inc, SPX Heat Transfer Inc, Foster Wheeler AG, Balcke-Dur GmbH, Alstom Power SA, Shanghai Electric Group Co. Ltd, Mitsubishi Heavy Industries Ltd, Larsen & Toubro Limited, Dongfang Electric Corp. Ltd, Toshiba, Doosan Corporation, Korea Electric Power Corporation, General Electric., and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Feed Water Heater for Power Plants Market: Regional Analysis

Asia Pacific to lead the market during the forecast period

The Asia Pacific region is expected to lead the global feed water heater market for power plants during the forecast period. This can be attributed to a combination of factors. Firstly, the region is experiencing rapid industrialization and urbanization, driving a surge in demand for electricity. For instance, according to the IEA World Energy Balances, in 2022 total energy supply in China and India reached around 150,000,000 terajoule and 36,000,000 terajoule respectively. As a result, there is a heightened focus on enhancing the efficiency and performance of power generation facilities, creating a significant market for feed water heaters.

Secondly, several countries in the Asia Pacific, such as China, India, and South Korea, have ambitious plans for expanding their power generation capacities. This necessitates the installation of advanced feed water heating systems to optimize thermal efficiency, further propelling market growth. Moreover, Asia Pacific is home to a burgeoning renewable energy sector, which complements the demand for feed water heaters. These systems play a crucial role in thermal power plants, whether coal-fired, gas-fired, or nuclear, by improving the overall energy conversion process. Additionally, ongoing technological advancements and a robust manufacturing sector in the region contribute to the availability of cutting-edge feed water heater solutions. All these factors combined position Asia Pacific as a dominant force in the global feed water heater market for power plants, expected to lead the way in the foreseeable future.

Key Developments

In 2023, KNM Group Berhad, a leading Malaysian engineering and construction company, acquired Thermal Engineering International Inc. (TEI), a Canadian manufacturer of feed water heaters. This acquisition strengthened KNM's position in the global feed water heater market and expanded its product portfolio.

In 2023, KNM Group Berhad launched a new line of feed water heaters that are designed for use in ultra-supercritical power plants. These new feed water heaters are more efficient and reliable than traditional feed water heaters, and they can help to reduce the operating costs of ultra-supercritical power plants.

In 2022, Foster Wheeler AG, a Swiss engineering and construction company, acquired Alstom Power SA, a French power generation equipment manufacturer. This acquisition gave Foster Wheeler a strong foothold in the global feed water heater market and access to Alstom's advanced technologies.

Feed Water Heater for Power Plants Market: Competitive Analysis

The global feed water heater for power plants market is dominated by players like:

- BWX Technologies Inc

- Westinghouse Electric Company LLC

- KNM Group Berhad

- Thermal Engineering International (USA) Inc

- SPX Heat Transfer Inc

- Foster Wheeler AG

- Balcke-Dur GmbH

- Alstom Power SA

- Shanghai Electric Group Co., Ltd

- Mitsubishi Heavy Industries, Ltd

- Larsen & Toubro Limited

- Dongfang Electric Corp. Ltd

- Toshiba, Doosan Corporation

- Korea Electric Power Corporation

- General Electric

The global feed water heater for power plants market is segmented as follows:

By Type

- Low-Pressure Heater

- High-Pressure Heater

By Application

- Steam-Powered Power Plant

- Gas-Powered Power Plant

- Nuclear-Powered Power Plant

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Feedwater heaters are crucial components in power plants that improve thermal efficiency by pre-heating water before it enters the boiler. This process reduces the amount of fuel needed to generate steam, resulting in significant energy savings and lower operational costs.

The global feed water heater for power plants market cap may grow owing to the due to increasing demand for electricity worldwide, driven by industrialization and urbanization.

According to study, the global feed water heater for power plants market size was worth around USD 14.2 billion in 2022 and is predicted to grow to around USD 24.3 billion by 2030.

The CAGR value of the feed water heater for power plants market is expected to be around 7.2% during 2023-2030.

The global feed water heater for power plants market growth is expected to be driven by Asia Pacific. It is currently the world’s highest revenue-generating market owing to the rapid industrialization and urbanization coupled with expanding power generation capacities by emerging countries.

The global feed water heater for power plants market is led by players like BWX Technologies Inc, Westinghouse Electric Company LLC, KNM Group Berhad, Thermal Engineering International (USA) Inc, SPX Heat Transfer Inc, Foster Wheeler AG, Balcke-Dur GmbH, Alstom Power SA, Shanghai Electric Group Co., Ltd, Mitsubishi Heavy Industries, Ltd, Larsen & Toubro Limited, Dongfang Electric Corp. Ltd, Toshiba, Doosan Corporation, Korea Electric Power Corporation, General Electric.

The report analyzes the global feed water heater for power plants market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the feed water heater for Power Plants industry.

Choose License Type

List of Contents

Feed Water Heater for Power PlantsIndustry Prospective:OverviewKey InsightsGrowth DriversRestraintsOpportunitiesChallengesSegmentationReport ScopeRegional AnalysisKey DevelopmentsCompetitive AnalysisThe global feed water heater for power plants market is segmented as follows:By RegionHappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed