Ferrofluidic Vacuum Seals Feedthrough Market Size, Share, Trends, Growth 2032

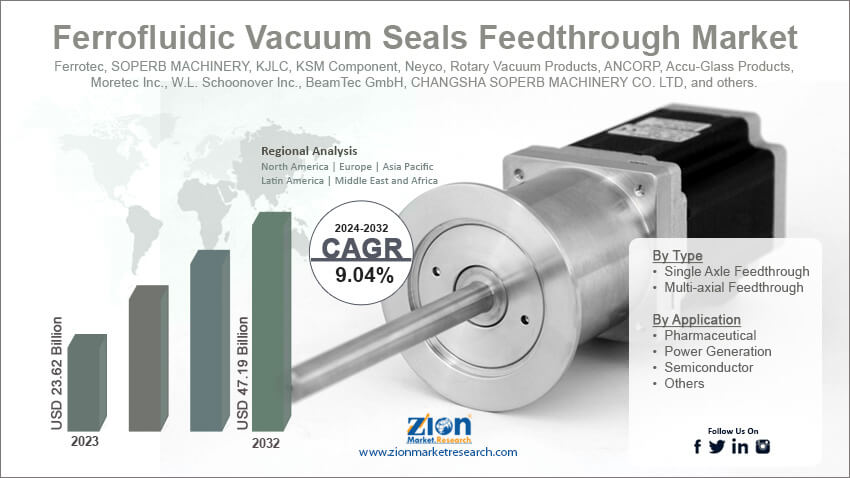

Ferrofluidic Vacuum Seals Feedthrough Market By Type (Single Axle Feedthrough and Multi-axial Feedthrough), By Application (Pharmaceutical, Power Generation, Semiconductor, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 – 2032

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 23.62 Billion | USD 47.19 Billion | 9.04% | 2023 |

Ferrofluidic Vacuum Seals Feedthrough Industry Prospective:

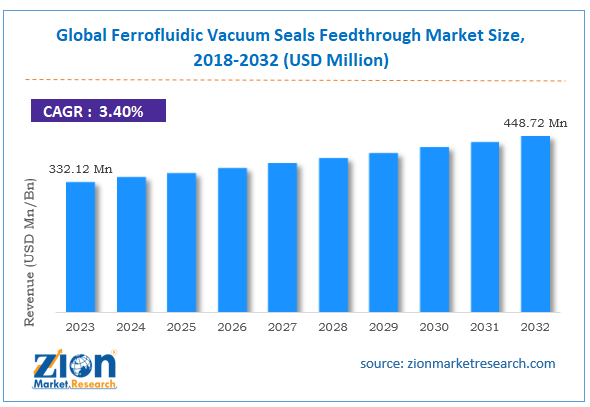

The global ferrofluidic vacuum seals feedthrough market size was worth around USD 332.12 million in 2023 and is predicted to grow to around USD 448.72 million by 2032 with a compound annual growth rate (CAGR) of roughly 3.4% between 2024 and 2032.

Ferrofluidic Vacuum Seals Feedthrough Market: Overview

A device that transfers mechanical power or rotation into a vacuum chamber or system using a magnetic fluid is called a ferrofluidic vacuum seal feedthrough. The device is utilized in vacuum systems and high-tech applications where mechanical components or electrical impulses need to pass through the vacuum with a dependable seal. The apparatus comprises a magnetically permeable shaft, two pole pieces, liquid ferrofluid, and a permanent magnet. Ferrofluidic vacuum seal feed-throughs are employed in the functional parts of semiconductor, FPD, LED, and solar cell manufacturing equipment. Additionally, they are employed in the rotating mechanisms of FPD panel transfer robots as well as in the etching and layer creation procedures for semiconductor wafers.

Key Insights

- As per the analysis shared by our research analyst, the global ferrofluidic vacuum seals feedthrough market is estimated to grow annually at a CAGR of around 3.4% over the forecast period (2024-2032).

- In terms of revenue, the global ferrofluidic vacuum seals feedthrough market size was valued at around USD 332.12 million in 2023 and is projected to reach USD 448.72 million by 2032.

- The growing semiconductor industry is expected to drive the ferrofluidic vacuum seal feedthrough industry over the forecast period.

- Based on the type, the single axle feedthrough segment is expected to dominate the market over the forecast period.

- Based on the application, the semiconductor segment is expected to capture a significant market share over the projected period.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Request Free Sample

Request Free Sample

Ferrofluidic Vacuum Seals Feedthrough Market: Growth Drivers

Growth in semiconductor manufacturing drives market growth

One of the biggest markets for ferrofluidic vacuum seal feed-throughs is the semiconductor sector. The growing need for semiconductors due to improvements in IoT, AI, 5G, and electronics has increased the requirement for precise and reliable vacuum sealing solutions. For instance, the unstoppable momentum of 5G technology pushed the wireless telecommunications industry to unprecedented growth and innovation in the past year. According to research from Omdia and 5G Americas, the voice of 5G and beyond in the Americas, the number of 5G connections worldwide increased by 700 million in 2023. Thus, the aforementioned stats propel the ferrofluidic vacuum seals feedthrough market over the projected period.

Ferrofluidic Vacuum Seals Feedthrough Market: Restraints

High cost and complexity of maintenance hinder market growth

Ferrofluidic vacuum seal feed-throughs are more costly than other sealing methods because they require sophisticated materials and precise engineering. This may discourage adoption, especially in the case of small and medium-sized businesses (SMEs) that do not have the funding available for such specialist machinery. Ferrofluidic vacuum seal feedthrough maintenance requires specific technological know-how and abilities. Handling and maintaining these seals can be challenging due to their intricacy, particularly in areas with a lack of technical experience. These seals can be less appealing for particular applications due to their frequent maintenance requirements and possible downtime, which can raise operating costs and reduce productivity. Thereby hampering the ferrofluidic vacuum seals feedthrough industry growth.

Ferrofluidic Vacuum Seals Feedthrough Market: Opportunities

Expansion of medical device manufacturing offers a lucrative opportunity for market growth

Vacuum systems with ferrofluidic feed-throughs are frequently used in medical devices requiring sterile, controlled settings. The market for these seals is anticipated to increase along with the medical device sector, especially in emerging markets. Large global corporations and small & medium-sized businesses (SMEs) that are expanding at an unprecedented rate make up India's medical device market, according to data released by Invest India. The last five years have seen a CAGR of 9–11% growth in the medical device export industry. By 2025, medical equipment exports from India are projected to total approximately $10 billion. Thus, the growing medical devices sector offers a lucrative opportunity for the ferrofluidic vacuum seals feedthrough industry.

Ferrofluidic Vacuum Seals Feedthrough Market: Challenges

Competition from alternative technology poses a major challenge to market expansion

Alternative sealing technologies, including mechanical and magnetic seals, which may provide adequate performance at a cheaper cost, are a competitive threat to the market. These options could be appealing in some circumstances since they require less upkeep or have lower initial expenses. The requirement for ferrofluidic solutions may decrease as alternative vacuum sealing technologies advance, especially in sectors where high precision is not as important. Thus posing a major challenge for the ferrofluidic vacuum seals feedthrough market.

Ferrofluidic Vacuum Seals Feedthrough Market: Segmentation

The global ferrofluidic vacuum seal feedthrough industry is segmented based on type, application, and region.

Based on the type, the global ferrofluidic vacuum seals feedthrough market is bifurcated into single axle feedthrough and multi-axial feedthrough. The single axle feedthrough segment is expected to dominate the market over the forecast period. One rotating shaft or axle can be used to transfer rotational motion over a vacuum boundary in a single axle feedthrough, a sort of ferrofluidic vacuum seal feedthrough. These parts are crucial for applications that need accurate and dependable motion in vacuum settings. The medical device sector is using vacuum systems with single axle feed-throughs more and more because manufacturing these devices needs controlled settings. The need for trustworthy sealing solutions increases along with the demand for cutting-edge medical devices, fueling the market's revenue growth. Furthermore, single axle feed-throughs are employed in the manufacturing of flexible and OLED displays, a couple of instances of cutting-edge display technology. Revenue in this market is driven by the increasing demand for dependable vacuum sealing solutions brought on by the widespread adoption of these technologies.

Based on the application, the global ferrofluidic vacuum seal feedthrough industry is bifurcated into pharmaceutical, power generation, semiconductor, and others. The semiconductor segment is expected to capture a significant market share over the projected period. Vacuum environments are necessary for processes like etching, chemical vapor deposition (CVD), and physical vapor deposition (PVD) in the semiconductor manufacturing industry to avoid contamination and guarantee accurate material deposition. Feedthroughs for ferrofluidic vacuum seals are utilized to transfer materials or motion while preserving the integrity of these vacuum systems. Furthermore, sophisticated vacuum chambers with mechanical and robotic systems that must function in a vacuum are used in semiconductor fabrication facilities. Ferrofluidic feed-throughs guarantee the proper operation of these systems without sacrificing the vacuum. The expansion of this industry is driven by these applications of ferrofluidic vacuum sealing feedthroughs.

Ferrofluidic Vacuum Seals Feedthrough Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Ferrofluidic Vacuum Seals Feedthrough Market |

| Market Size in 2023 | USD 332.12 Million |

| Market Forecast in 2032 | USD 448.72 Million |

| Growth Rate | CAGR of 3.4% |

| Number of Pages | 222 |

| Key Companies Covered | Ferrotec, SOPERB MACHINERY, KJLC, KSM Component, Neyco, Rotary Vacuum Products, ANCORP, Accu-Glass Products, Moretec Inc., W.L. Schoonover Inc., BeamTec GmbH, CHANGSHA SOPERB MACHINERY CO. LTD, and others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Ferrofluidic Vacuum Seals Feedthrough Market: Regional Analysis

Asia Pacific leads the market over the projected period

The Asia Pacific is expected to lead the global ferrofluidic vacuum seal feedthrough market growth during the forecast period. The expansion of the market is attributable to the rapid growth in the semiconductor industry. Asia Pacific is a major hub for the production of semiconductors, especially for nations like China, Taiwan, South Korea, and Japan. Strong investments in semiconductor fabs in the area are driving demand for superior vacuum sealing products, such as ferrofluidic feed-throughs. Ferrofluidic seals are becoming more and more popular as a result of the drive for better semiconductor technologies, which include smaller and more effective devices that demand reliable vacuum conditions. Moreover, the nations in the region are making significant R&D investments, especially in areas like biotechnology, materials science, and nanotechnology. Sophisticated vacuum systems—including those that use ferrofluidic feed-throughs—are needed for these research endeavors. Therefore driving the ferrofluidic vacuum seal feedthrough market in the region.

Ferrofluidic Vacuum Seals Feedthrough Market: Competitive Analysis

The global ferrofluidic vacuum seals feedthrough market is dominated by players like:

- Ferrotec

- SOPERB MACHINERY

- KJLC

- KSM Component

- Neyco

- Rotary Vacuum Products

- ANCORP

- Accu-Glass Products

- Moretec Inc.

- W.L. Schoonover Inc.

- BeamTec GmbH

- CHANGSHA SOPERB MACHINERY CO. LTD

The global ferrofluidic vacuum seals feedthrough market is segmented as follows:

By Type

- Single Axle Feedthrough

- Multi-axial Feedthrough

By Application

- Pharmaceutical

- Power Generation

- Semiconductor

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A device that transfers mechanical power or rotation into a vacuum chamber or system using a magnetic fluid is called a ferrofluidic vacuum seal feedthrough. The device is utilized in vacuum systems and high-tech applications where mechanical components or electrical impulses need to pass through the vacuum with a dependable seal. The apparatus consists of a magnetically permeable shaft, two pole pieces, liquid ferrofluid, and a permanent magnet. Ferrofluidic vacuum seal feedthroughs are employed in the functional parts of semiconductor, FPD, LED, and solar cell manufacturing equipment. Additionally, they are employed in the rotating mechanisms of FPD panel transfer robots as well as in the etching and layer creation procedures for semiconductor wafers.

The ferrofluidic vacuum seal feedthrough market is being driven by several factors, such as the growing semiconductor industry, expansion of the medical devices sector, technological advancements, rising investment in R&D, advancements in display technologies, and others.

According to the report, the global ferrofluidic vacuum seal feedthrough market size was worth around USD 332.12 million in 2023 and is predicted to grow to around USD 448.72 million by 2032.

The global ferrofluidic vacuum seal feedthrough market is expected to grow at a CAGR of 3.4% during the forecast period.

Which region will contribute notably towards the ferrofluidic vacuum seals feedthrough market value?

The global ferrofluidic vacuum seal feedthrough market growth is expected to be driven by the Asia Pacific. It is currently the world’s highest revenue-generating market due to rapid growth in the medical device sector.

The global ferrofluidic vacuum seals feedthrough market is dominated by players like Ferrotec, SOPERB MACHINERY, KJLC, KSM Component, Neyco, Rotary Vacuum Products, ANCORP, Accu-Glass Products, Moretec Inc, W.L. Schoonover Inc., BeamTec GmbH and CHANGSHA SOPERB MACHINERY CO., LTD among others.

The ferrofluidic vacuum seal feedthrough market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

Choose License Type

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed