Hydrogen Gas Separation Membrane Market Size, Share, Trends, Growth 2034

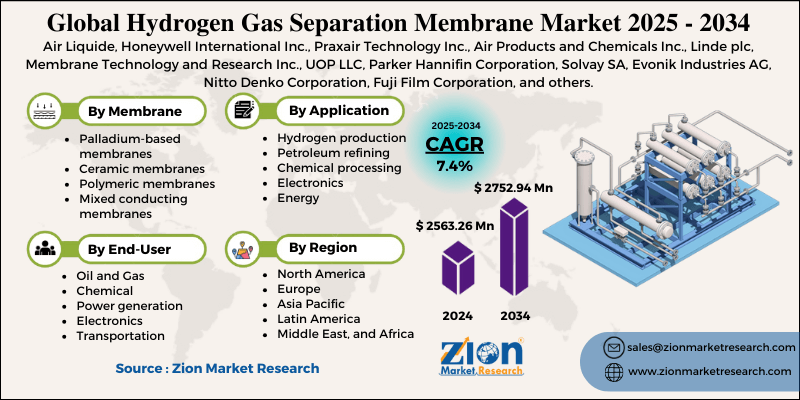

Hydrogen Gas Separation Membrane Market By Membrane Type (Palladium-Based Membranes, Ceramic Membranes, Polymeric Membranes, Mixed Conducting Membranes), By Application (Hydrogen Production, Petroleum Refining, Chemical Processing, Electronics, Energy), By End-User Industry (Oil and Gas, Chemical, Power Generation, Electronics, Transportation), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

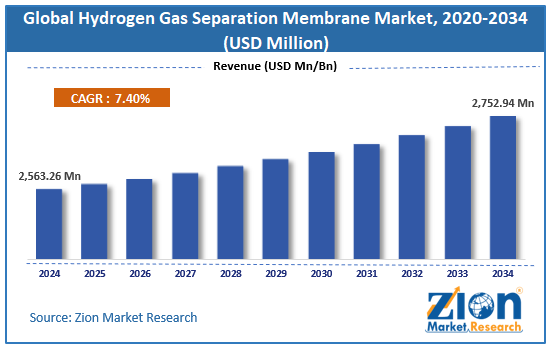

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2,563.26 Million | USD 2,752.94 Million | 7.40% | 2024 |

Hydrogen Gas Separation Membrane Industry Prospective:

The global hydrogen gas separation membrane market size was valued at approximately USD 2,563.26 million in 2024 and is expected to reach around USD 2,752.94 million by 2034, growing at a compound annual growth rate (CAGR) of roughly 7.40% between 2025 and 2034.

Hydrogen Gas Separation Membrane Market: Overview

Hydrogen gas separation membranes are specialized technological solutions designed to separate hydrogen from complex gas mixtures with high efficiency and precision. This is a critical technology for the global energy transition, clean hydrogen production, and advanced industrial processes.

Hydrogen gas separation membranes extract pure hydrogen for emerging clean energy technologies, industrial applications, and sustainable manufacturing processes. The market is key to decarbonization, green hydrogen, and advanced technologies across multiple industries.

Over the forecast period, the global focus on clean energy, hydrogen economy, and membrane separation technology developments will drive the hydrogen gas separation membrane industry growth. Government policies, carbon neutrality targets, and increased investment in hydrogen infrastructure will further accelerate market growth and technology development.

Key Insights:

- As per the analysis shared by our research analyst, the global hydrogen gas separation membrane market is estimated to grow annually at a CAGR of around 7.40% over the forecast period (2025-2034)

- In terms of revenue, the global hydrogen gas separation membrane market size was valued at around USD 2563.26 million in 2024 and is projected to reach USD 2752.94 million by 2034.

- The hydrogen gas separation membrane market is projected to grow significantly due to increasing global decarbonization efforts, rising hydrogen economy investments, technological innovations in membrane separation, increasing demand for clean energy solutions, and expanding industrial applications.

- Based on membrane type, palladium-based membranes lead the segment and will continue to dominate the global market.

- Based on application, hydrogen production is anticipated to command the largest market share by the end of the forecast period.

- Based on end-user industries, the oil and gas sector will remain dominant during the forecast period.

- Based on region, North America is projected to dominate the global market during the forecast period.

Hydrogen Gas Separation Membrane Market: Growth Drivers

Global decarbonization and clean energy transition

Global decarbonization efforts are driving unprecedented market expansion in the hydrogen gas separation membrane industry. Governments and enterprises worldwide are investing in hydrogen as a clean energy alternative to fossil fuels.

According to recent industry surveys, investments in hydrogen infrastructure and separation technologies have grown significantly over the last 3 years. The need to reduce carbon emissions and develop sustainable energy options is speeding up innovation in hydrogen gas separation membranes.

Plus, membrane materials and engineering advancements make them more efficient, cheaper, and scalable for large-scale hydrogen production. Collaborations between energy companies and research institutions are driving innovation and commercialization in the space.

Technological innovation and industrial efficiency

Advanced hydrogen gas separation membranes transform industrial processes by enabling more efficient, precise, and cost-effective hydrogen extraction. Emerging membrane technologies offer better separation, lower energy consumption, and improved performance across multiple industrial applications.

Manufacturers are developing new membrane materials and designs that can operate in extreme conditions, providing unparalleled precision and reliability in hydrogen separation. Research into nanostructured and composite membranes further improves selectivity, permeability, and long-term operational stability for next-generation hydrogen separation solutions.

Advancements in membrane surface modifications and catalytic coatings are further enhancing hydrogen purity levels while minimizing fouling and degradation over extended operational lifetimes.

Hydrogen Gas Separation Membrane Market: Restraints

Technological complexity and high development costs

Hydrogen gas separation membrane technologies require substantial research, development, and manufacturing investments. The membrane design is complex, material science is challenging, and the performance requirements are stringent.

Advanced membrane technologies need a lot of expertise, high-technology manufacturing, and continuous innovation. The high capital expenditure and technical complexity make it hard for new players to enter and slow the overall growth of the hydrogen gas separation membrane industry.

The regulatory compliance and certification process adds to the challenge; manufacturers must meet industry safety and efficiency standards. Strategic partnerships and government-funded research are becoming essential to overcome these barriers and accelerate market growth.

Hydrogen Gas Separation Membrane Market: Opportunities

Emerging hydrogen economy and clean energy infrastructure

The move to a hydrogen economy opens up enormous opportunities for hydrogen gas separation membrane technologies. Governments and private companies invest billions in hydrogen infrastructure, green hydrogen production, and clean energy.

Membranes that can separate hydrogen efficiently and economically will be key to sustainable energy systems. Combining technology innovation, policy support, and industrial demand is a game changer for membrane separation technologies.

Nanomaterials and membrane engineering advances are improving separation efficiency, reducing cost, and driving adoption across many industries.

Hydrogen Gas Separation Membrane Market: Challenges

Material durability and performance consistency

Hydrogen gas separation membranes have material durability, performance consistency, and operational stability challenges. Hydrogen’s unique chemistry causes complex interactions with the membrane material, leading to degradation, reduced performance, and operational limitations.

Manufacturers must develop membranes that perform well under different industrial conditions, temperature ranges, and chemical environments. Composite and hybrid membrane materials are being developed to increase durability and extend operational life. Testing protocols and advanced coating technologies improve hydrogen embrittlement resistance and permeability loss.

Research into nano-engineered membrane structures and high-performance alloys drives innovation to enhance membrane efficiency and long-term reliability in demanding applications.

Hydrogen Gas Separation Membrane Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Hydrogen Gas Separation Membrane Market |

| Market Size in 2024 | USD 2563.26 Million |

| Market Forecast in 2034 | USD 2752.94 Million |

| Growth Rate | CAGR of 7.40% |

| Number of Pages | 211 |

| Key Companies Covered | Air Liquide, Honeywell International Inc., Praxair Technology Inc., Air Products and Chemicals Inc., Linde plc, Membrane Technology and Research Inc., UOP LLC, Parker Hannifin Corporation, Solvay SA, Evonik Industries AG, Nitto Denko Corporation, Fuji Film Corporation, and others. |

| Segments Covered | By Membrane Type, By Application, By End-User Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Hydrogen Gas Separation Membrane Market: Segmentation

The global hydrogen gas separation membrane market is segmented into membrane type, application, end-user industry, and region.

Based on membrane type, the hydrogen gas separation membrane industry is segregated into palladium-based membranes, ceramic membranes, polymeric membranes, and mixed conducting membranes. Palladium-based membranes lead the market by offering superior hydrogen separation capabilities and exceptional performance.

Based on application, the hydrogen gas separation membrane market is divided into hydrogen production, petroleum refining, chemical processing, electronics, and energy sectors. Hydrogen production dominates the market, driven by growing clean energy initiatives and industrial hydrogen demand.

Based on end-user industries, the market is categorized into oil and gas, chemical, power generation, electronics, and transportation sectors. The oil and gas industry leads the market due to extensive hydrogen processing requirements and established industrial infrastructure.

Hydrogen Gas Separation Membrane Market: Regional Analysis

North America to lead the market

North America leads the global hydrogen gas separation membrane market due to technology leadership, clean energy infrastructure investments, and robust research ecosystems. The U.S. is at the forefront of membrane technology development, with major companies and research institutions driving innovation.

Advanced industrial infrastructure, supportive government policies, and significant venture capital investments create a membrane technology-friendly environment. Government agencies, private companies, and academic institutions are working to accelerate hydrogen research and development. Hydrogen fuel cell vehicles and industrial hydrogen adoption are growing, with the demand for efficient separation technologies.

North America has a growing network of hydrogen refueling stations and pipeline infrastructure, and federal initiatives and funding programs are driving membrane efficiency, durability, and large-scale deployment. Energy companies and technology providers are partnering to create a competitive and fast-evolving market.

Advancements in composite and polymeric membrane materials are enhancing hydrogen separation efficiency, making next-generation membranes more viable for widespread industrial applications. The region's focus on carbon capture and utilization (CCU) is further propelling the development of membrane-based hydrogen purification solutions to support decarbonization goals.

Asia Pacific is to demonstrate rapid growth.

Asia Pacific is a fast-growing market for hydrogen gas separation membranes as industrial sectors expand, clean energy investments increase, and technology modernizes. Countries like Japan, South Korea, and China are investing heavily in hydrogen infrastructure and membrane technology. The region’s manufacturing base is growing rapidly and decarbonizing fast, creating significant opportunities for membrane adoption.

Government-backed hydrogen strategies such as Japan’s Hydrogen Roadmap and South Korea’s Hydrogen Economy Plan drive the market. China’s push for hydrogen transportation and industrial hydrogen creates a massive demand for advanced membrane technology.

Regional energy and global technology firms collaborate increasingly, driving innovation and growth. The presence of big chemical and material science companies in the region also supports membrane research and production.

Asia Pacific’s growing focus on sustainable industrial practices and green energy adoption will continue to shape the trajectory of the hydrogen gas separation membrane market.

Furthermore, the increasing emphasis on cost-effective, scalable hydrogen solutions and ongoing advancements in nanomaterial-based membranes are expected to accelerate the commercialization and large-scale adoption of hydrogen separation technologies across various regional industries.

As governments strengthen carbon neutrality goals and hydrogen production incentives, the region is poised to become a key hub for next-generation hydrogen separation membrane technologies, fostering long-term industry expansion.

Recent Market Developments:

- In January 2025, Air Liquide introduced advanced palladium-based hydrogen separation membranes with unprecedented purity and efficiency levels.

- In March 2025, Honeywell launched next-generation mixed conducting membranes designed for extreme industrial applications and enhanced hydrogen separation capabilities.

Hydrogen Gas Separation Membrane Market: Competitive Analysis

The global hydrogen gas separation membrane market is led by players like:

- Air Liquide

- Honeywell International Inc.

- Praxair Technology Inc.

- Air Products and Chemicals Inc.

- Linde plc

- Membrane Technology and Research Inc.

- UOP LLC

- Parker Hannifin Corporation

- Solvay SA

- Evonik Industries AG

- Nitto Denko Corporation

- Fuji Film Corporation

The hydrogen gas separation membrane market is segmented as follows:

By Membrane Type

- Palladium-based membranes

- Ceramic membranes

- Polymeric membranes

- Mixed conducting membranes

By Application

- Hydrogen production

- Petroleum refining

- Chemical processing

- Electronics

- Energy

By End-User Industry

- Oil and Gas

- Chemical

- Power generation

- Electronics

- Transportation

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Hydrogen gas separation membranes are specialized technological solutions designed to separate hydrogen from complex gas mixtures with high efficiency and precision.

The hydrogen gas separation membrane market is expected to be driven by global decarbonization efforts, hydrogen economy development, technological innovations, increasing clean energy investments, and expanding industrial applications of hydrogen technologies.

According to our study, the global hydrogen gas separation membrane market was worth around USD 2563.26 million in 2024 and is predicted to grow to around USD 2752.94 million by 2034.

The CAGR value of the hydrogen gas separation membrane market is expected to be around 7.40% during 2025-2034.

The global hydrogen gas separation membrane market will register the highest growth in North America during the forecast period.

Key players in the hydrogen gas separation membrane market include Air Liquide, Honeywell International Inc., Praxair Technology, Inc., Air Products and Chemicals, Inc., Linde plc, Membrane Technology and Research, Inc., UOP LLC, Parker Hannifin Corporation, Solvay SA, Evonik Industries AG, Nitto Denko Corporation, and Fuji Film Corporation.

The report provides a comprehensive analysis of the hydrogen gas separation membrane market, offering an in-depth exploration of technological innovations, market dynamics, competitive landscape, and future growth opportunities across global regions. It thoroughly examines market drivers, emerging trends, regional dynamics, and potential challenges. It is a strategic resource for stakeholders seeking to understand the evolving hydrogen separation membrane ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed