Lithium-Ion Battery Separator Market Size, Share, Analysis, Forecasts, 2032

Lithium-Ion Battery Separator Market By Material (Polypropylene (PP), Polyethylene (PE), Nylon, and Others), By Thickness (16µm, 20µm, and 25µm), By End User (Industrial, Consumer Electronics, Automotive, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032-

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

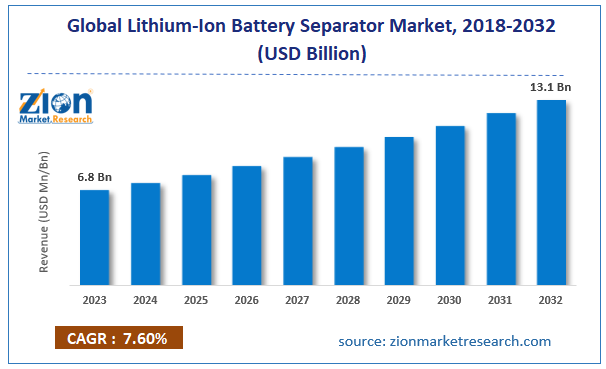

| USD 6.8 Billion | USD 13.1 Billion | 7.6% | 2023 |

Lithium-Ion Battery Separator Industry Prospective:

The global lithium-ion battery separator market size was around USD 6.8 billion in 2023 and is predicted to grow to around USD 13.1 billion by 2032, with a compound annual growth rate (CAGR) of roughly 7.6% between 2024 and 2032.

Lithium-Ion Battery Separator Market: Overview

A separator is a necessary component of a lithium-ion battery that allows the effective flow of ions and prevents electrically short-circuiting of the positive and negative electrodes.

Preserving suitable ion transport and thermal stability ensures the safe operation of this porous, electrically insulating material. Devices ranging from computers to cellphones and electric autos to renewable energy storage systems use lithium-ion battery separators.

Future lithium-ion battery separators must include improvements in materials and technologies if the goal is to raise energy density, performance, and safety. Development in nanotechnology and complex polymer materials is expected to enhance separator performance, reduce the likelihood of thermal runaway, and fulfill the growing need for high-performance batteries in innovative technologies.

Key Insights

- As per the analysis shared by our research analyst, the global lithium-ion battery separator market is estimated to grow annually at a CAGR of around 7.6% over the forecast period (2024-2032).

- In terms of revenue, the global lithium-ion battery separator market size was valued at around USD 6.8 billion in 2023 and is projected to reach USD 13.1 billion by 2032.

- The growing demand for EVs across the globe is expected to drive the lithium-ion battery separator market over the forecast period.

- Based on the material, the Polypropylene (PP) segment is expected to hold the largest market share over the forecast period.

- Based on the thickness, the 16µm segment is expected to dominate the market expansion over the projected period.

- Based on the end-user, the consumer electronics segment is expected to capture the largest market share over the projected period.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Lithium-Ion Battery Separator Market: Growth Drivers

Increasing demand for electric vehicles drives market growth

One of the primary drivers pushing the lithium-ion battery separator market is the increasing global use of electric vehicles (EVs). As governments all around tighten emission limits, there has never been more demand for electric mobility.

Lowering the entrance barrier for EVs includes tax cuts, subsidies, and infrastructure building, including charging stations. Key elements in the success of electric cars are the lifespan, safety, and efficiency of lithium-ion batteries.

Making sure these needs are met depends critically on battery separators, which act as a safety layer and help to prevent issues, including internal short circuits and thermal runaway.

As the number of electric vehicles on the road increases, high-quality separators and lithium-ion batteries are in ever-increasing demand. Manufacturers in the battery separator industry are raising their manufacturing capacity and investing in research and development to create separators that satisfy tight automotive quality criteria.

Lithium-Ion Battery Separator Market: Restraints

High manufacturing cost hinders market growth

High production costs are one of the key elements restricting the lithium-ion battery separator industry. These high prices, which have several causes, affect the scalability and cost of manufacturing lithium-ion batteries. Separators are made from polyethylene (PE), polypropylene (PP), and ceramic-coated materials; these materials must be produced under rigorous standards. High-performance multilayer and ceramic-coated separators improve battery longevity and safety even if their fabrication is more expensive.

Moreover, stretching, coating, and porosity control require highly sophisticated equipment and strict quality control. Further polymer modification and stacking in shutdown separators—which close holes at high temperatures for safety—raise production costs.

Lithium-Ion Battery Separator Market: Opportunities

The rising product launch offers a lucrative opportunity for market growth

The rising product launch is expected to offer a lucrative opportunity for the Lithium-Ion Battery Separator market over the forecast period. For instance, in October 2024, the OmniSepTM Battery Separator, a state-of-the-art solution for the lithium-ion battery market, was introduced by Glatfelter Corporation, a prominent worldwide producer of engineered materials.

The outcome of intensive research and development targeted at improving electrical energy storage methods is this ground-breaking innovation. A battery separator that supports high charge and discharge rates (up to 16C pulse discharge), improves safety, has features that can be customized to fit different battery chemistries, and is entirely made in the US is what OmniSepTM was created to address.

With high porosity for enhanced ionic conductivity and quick charging capabilities, the OmniSepTM production platform enables the separator to be customized for a particular application. To extend its shelf life, its pore size might be reduced. To satisfy the temperature and safety specifications of each application, a variety of polymers can be employed. There is no need for ceramic coatings because the standard grades of 15 and 22µm are thermally stable up to 150ºC, while the developmental grades are stable up to 200ºC.

Lithium-Ion Battery Separator Market: Challenges

Environmental and recycling concern poses a major challenge to market expansion

Environmental and recycling problems provide major obstacles to the lithium-ion battery separator sector since separator materials are not biodegradable and recycling processes are difficult. Non-biodegradable polyethylene (PE) and polypropylene (PP) make up most of the lithium-ion battery separators, which add to the waste created by plastic.

Particularly in landfills and incineration plants, the disposal of used battery separators causes environmental contamination.

Furthermore, this hazardous chemical waste is the solvent-based extraction used in the wet process of separator manufacture. The strict environmental restrictions required to control and dispose of these solvents increase compliance costs.

Lithium-Ion Battery Separator Market : Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Lithium-Ion Battery Separator Market |

| Market Size in 2023 | USD 6.8 Billion |

| Market Forecast in 2032 | USD 13.1 Billion |

| Growth Rate | CAGR of 7.6% |

| Number of Pages | 222 |

| Key Companies Covered | Asahi Kasei Corporation, Beijing SOJO Electric Co. Ltd., Cangzhou Mingzhu Plastic Co. Ltd., Mitsubishi Paper Mills Limited (Oji Paper Co. Ltd.), ENTEK International LLC, Shanghai Energy New Materials Technology Co. Ltd., Sumitomo Chemical Co. Ltd., SK Innovation Co. Ltd., Teijin Limited, Toray Industries Inc., UBE Corporation, W-SCOPE Corporation, and others. |

| Segments Covered | By Material, By Thickness, By End User, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Lithium-Ion Battery Separator Market: Segmentation

The global lithium-ion battery separator industry is segmented based on material, thickness, end-user, and region.

Based on the material, the global lithium-ion battery separator market is bifurcated into Polypropylene (PP), Polyethylene (PE), Nylon, and Others. The Polypropylene (PP) segment is expected to hold the largest market share over the forecast period. Polypropylene (PP) is a widely used material in lithium-ion battery separators due to its excellent chemical stability, mechanical strength, and cost-effectiveness.

Based on the thickness, the global lithium-ion battery separator industry is bifurcated into 16µm, 20µm, and 25µm. The market is dominated by the 16µm thickness category, which provides a good mix of affordability and performance. It is appropriate for a range of applications due to its thickness, which guarantees effective ion transport, mechanical strength, thermal stability, and a higher energy density.

Based on the end-user, the global lithium-ion battery separator market is bifurcated into industrial, consumer electronics, automotive, and others. The consumer electronics segment is expected to capture the largest market share over the projected period. Separator demand has increased as a result of the widespread use of smartphones, laptops, tablets, and wearable technology, which has increased the need for reliable and efficient lithium-ion batteries.

Lithium-Ion Battery Separator Market: Regional Analysis

Asia Pacific dominates the market over the projected period

The Asia Pacific is expected to dominate the global lithium-ion battery separator market. The government's commitment to infrastructure development and the robust battery manufacturing bases in China, Japan, and India are expected to drive the growth of the regional market.

Furthermore, it is projected that the growing number of fast-moving consumer goods (FMCG) companies in China, Singapore, and India will raise battery consumption, driving market growth throughout the projection period.

Additionally, it is expected that rapid industrialization, growing FDIs, and government infrastructure expenditure will all promote market expansion.

Lithium-Ion Battery Separator Market: Competitive Analysis

The global lithium-ion battery separator market is dominated by players like

- Asahi Kasei Corporation

- Beijing SOJO Electric Co. Ltd.

- Cangzhou Mingzhu Plastic Co. Ltd.

- Mitsubishi Paper Mills Limited (Oji Paper Co. Ltd.)

- ENTEK International LLC

- Shanghai Energy New Materials Technology Co. Ltd.

- Sumitomo Chemical Co. Ltd.

- SK Innovation Co. Ltd.

- Teijin Limited

- Toray Industries Inc.

- UBE Corporation

- W-SCOPE Corporation

The global lithium-ion battery separator market is segmented as follows:

By Material

- Polypropylene (PP)

- Polyethylene (PE)

- Nylon

- Others

By Thickness

- 16µm

- 20µm

- 25µm

By End User

- Industrial

- Consumer Electronics

- Automotive

- Others

By Region

-

North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A separator is a necessary component of a lithium-ion battery that allows the effective flow of ions and prevents electrically short-circuiting of the positive and negative electrodes.

The lithium-ion battery separator market is expanding due to several factors, such as the growing adoption of EVs across the globe, increasing product launches, growth in the consumer electronics industry, technological advancements, and many others.

According to the report, the global lithium-ion battery separator market size was worth around USD 6.8 billion in 2023 and is predicted to grow to around USD 13.1 billion by 2032.

The global lithium-ion battery separator market is expected to grow at a CAGR of 7.6% during the forecast period.

The global lithium-ion battery separator market growth is expected to be driven by the Asia Pacific. It is currently the world’s highest revenue-generating market due to the presence of major players and the growing consumer electronics industry.

The global lithium-ion battery separator market is dominated by players like Asahi Kasei Corporation, Beijing SOJO Electric Co. Ltd., Cangzhou Mingzhu Plastic Co. Ltd., Mitsubishi Paper Mills Limited (Oji Paper Co. Ltd.), ENTEK International LLC, Shanghai Energy New Materials Technology Co. Ltd., Sumitomo Chemical Co. Ltd., SK Innovation Co. Ltd., Teijin Limited, Toray Industries Inc., UBE Corporation and W-SCOPE Corporation among others.

The lithium-ion battery separator market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed