Metal Cutting Machine Market Size, Share, Trends, Growth 2032

Metal Cutting Machine Market By Product (Laser Cutting Machine, Waterjet Cutting Machine, Plasma Cutting Machine, and Flame Cutting Machine), By Application (Automotive, Defense & Aerospace, Construction, Marine, Electrical & Electronics, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

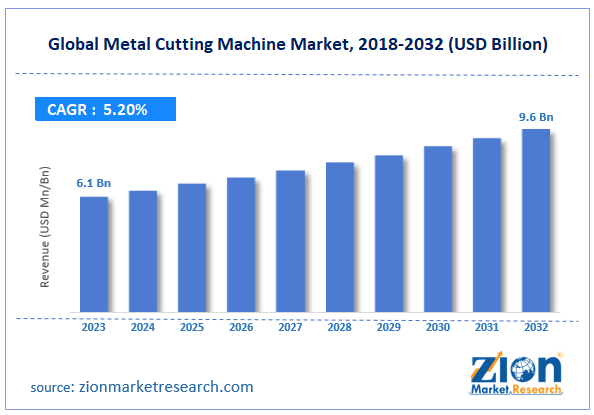

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 6.1 Billion | USD 9.6 Billion | 5.2% | 2023 |

Metal Cutting Machine Industry Prospective:

The global metal cutting machine market size was worth around USD 6.1 billion in 2023 and is predicted to grow to around USD 9.6 billion by 2032 with a compound annual growth rate (CAGR) of roughly 5.2% between 2024 and 2032.

Metal Cutting Machine Market: Overview

A metal cutting machine is a tool used in line with specified criteria to remove material from a metal workpiece, thereby finishing, shaping, or sizing it. These devices apply mechanical, thermal, and electrical cutting methods, among others. There are many sectors that use these machines, including industrial, automotive, aerospace, and construction, these tools are routinely used to offer precision metal shaping and finishing.

Growing demand from industries, including electronics, automotive, aerospace, and energy, is driving a consistent expansion in the metal cutting machine market. Precision production depends on these tools since they enable fast shaping and finishing of metal parts.

Key Insights

- As per the analysis shared by our research analyst, the global metal cutting machine market is estimated to grow annually at a CAGR of around 5.2% over the forecast period (2024-2032).

- In terms of revenue, the global metal cutting machine market size was valued at around USD 6.1 billion in 2023 and is projected to reach USD 9.6 billion by 2032.

- The growing automotive sector is expected to drive the metal cutting machine market over the forecast period.

- Based on the product, the laser cutting machine segment is expected to hold the largest market share over the forecast period.

- Based on the application, the automotive segment is expected to dominate the market over the forecast period.

- Based on region, Europe is expected to dominate the market during the forecast period.

Metal Cutting Machine Market: Growth Drivers

Growth of manufacturing machinery industries drives market growth.

The engineering and equipment markets now have a stronger base due to increased investments in the industrial machinery sector.

In addition to the traditional markets for exporters of these machines, the markets for CNC metal-cutting machines in Eastern and Central Europe have an enormous amount of potential because of economic development. The engineering and machinery sectors in emerging countries are also of considerable interest to foreign investors since they can offer several advantages in terms of innovation, technology, and manufacturing prices.

In addition, the railway, electrical, and packing industries are experiencing an increase in demand for machinery. It is anticipated that this will boost the metal cutting machine market's growth by raising demand for CNC metal-cutting equipment in the years to come.

Metal Cutting Machine Market: Restraints

Shortages of skilled workforce hinder market growth

One of the biggest issues faced by the metal cutting machine industry is the lack of trained workers, which impacts efficiency, production, and the uptake of cutting-edge technologies. For 5-axis, laser, and CNC milling equipment to function effectively, specialized training is necessary. Inaccurate cutting, long setup times, and ineffective manufacturing are the results of undertrained workers. To make up for the lack of workers, firms are also investing in automation, which raises operating expenses. Although automation is helpful, maintaining and fixing it still demands technical know-how and programming skills.

Metal Cutting Machine Market: Opportunities

Growing product launch offers a lucrative opportunity for market growth

The growing product launch is expected to flourish the metal cutting machine market expansion during the projected period. For instance, in August 2024, the latest L Series device from Bodor, a market leader in laser technology, will advance large-size sheet metal laser cutting.

With its segmented processing loop and ultra-large format construction, the L series combines precision, efficiency, and vast output to provide a comprehensive solution for a wide range of demanding industry needs.

With its sophisticated features and outstanding performance in processing welded structural steel, the L series increases productivity and safety when cutting I-beams and H-beams with ease. The L series' big format is crucial for construction equipment and is especially well-suited for producing large-scale parts for the construction machinery industry. The L series also meets the requirements of high-end metal production products with exceptional quality and operational efficacy.

Metal Cutting Machine Market: Challenges

Competition from alternative technologies poses a major challenge to market expansion

Alternative technologies that, in some applications, provide more efficiency, flexibility, and cost-effectiveness are becoming a bigger threat to the market for metal cutting machines. These substitutes, which include composite materials, laser cutting, and additive manufacturing (3D printing), are changing the market. Thus, the competition from alternative technologies poses a major challenge for the metal cutting machine market over the forecast period.

Metal Cutting Machine Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Metal Cutting Machine Market |

| Market Size in 2023 | USD 6.1 Billion |

| Market Forecast in 2032 | USD 9.6 Billion |

| Growth Rate | CAGR of 5.2% |

| Number of Pages | 219 |

| Key Companies Covered | TRUMPF, AMADA Co. Ltd., ESAB Corporation, Bystronic Laser AG, WARDJet, Koike Aronson Inc., Nissan Tanaka Corporation, Lincoln Electric Company, Water Jet Sweden AB, Flow International Corporation, Coherent Corp., Messer Cutting Systems GmbH, Omax Corporation, Boye Laser Applied Technology Co. Ltd., Han's Laser Technology Industry Group Co. Ltd., and others. |

| Segments Covered | By Product, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Metal Cutting Machine Market: Segmentation

The global metal cutting machine industry is segmented based on product, application, and region.

Based on the product, the global metal cutting machine market is bifurcated into laser cutting machine, waterjet cutting machine, plasma cutting machine, and flame cutting machine. The laser-cutting machine segment is expected to hold the largest market share over the forecast period. Compared to mechanical cutting, these machines offer superior precision and power economy. They perform remarkably well on hard metals like mild steel and steel but not on highly reflective metals like copper and aluminum. Thus driving the market growth.

Based on the application, the global metal cutting machine industry is segmented into automotive, defense & aerospace, construction, marine, electrical & electronics, and others. The automotive segment is expected to dominate the market over the forecast period. Metal-cutting machines are widely used in the automobile industry to cut a variety of external and interior parts for passenger vehicles and SUVs. Components, including door panels, chassis, weather stripping, and carpets, are also made using these machines.

Metal Cutting Machine Market: Regional Analysis

Europe dominates the market over the projected period

Europe is expected to dominate the global metal cutting machine market in the years to come. IoT, AI, and Industry 4.0-powered metal cutting tools increase precision and productivity while meeting the evolving demands of industries, including aircraft, automotive, and equipment.

Additionally, as industrial processes have become more automated, increasing output rates and lowering operational costs, the use of advanced metal-cutting machines has grown. Manufacturers are responding to tighter restrictions and growing environmental concerns by investing in energy-efficient metal cutting equipment, which is driving market expansion.

On the other hand, the Asia Pacific is expected to grow at the fastest rate over the forecast period. For aircraft producers, the area offers an array of prospects in general aviation, maintenance, repair, and overhaul, as well as the production of military equipment.

Furthermore, it is anticipated that in the next years, the swift economic advancements in nations like China and India will increase demand for the product. Due to the machine's superior optical qualities, including coherence, diffraction, monochromaticity, and radiance, metal cutting machines are widely used in the construction, automotive, aerospace, and defense industries. This is anticipated to be one of the key factors driving market growth in this region.

Metal Cutting Machine Market: Competitive Analysis

The global metal cutting machine market is dominated by players like:

- TRUMPF

- AMADA Co. Ltd.

- ESAB Corporation

- Bystronic Laser AG

- WARDJet

- Koike Aronson Inc.

- Nissan Tanaka Corporation

- Lincoln Electric Company

- Water Jet Sweden AB

- Flow International Corporation

- Coherent Corp.

- Messer Cutting Systems GmbH

- Omax Corporation

- Boye Laser Applied Technology Co. Ltd.

- Han's Laser Technology Industry Group Co. Ltd.

The global metal cutting machine market is segmented as follows:

By Product

- Laser Cutting Machine

- Waterjet Cutting Machine

- Plasma Cutting Machine

- Flame Cutting Machine

By Application

- Automotive

- Defense & Aerospace

- Construction

- Marine

- Electrical & Electronics

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A metal cutting machine is a tool used in line with specified criteria to remove material from a metal workpiece, thereby finishing, shaping, or sizing it. These devices apply mechanical, thermal, and electrical cutting methods, among others.

The metal cutting machine market is driven by increasing demand from end-use industries, technological advancements, growing product innovation, and others.

According to the report, the global metal cutting machine market size was worth around USD 6.1 billion in 2023 and is predicted to grow to around USD 9.6 billion by 2032.

The global metal cutting machine market is expected to grow at a CAGR of 5.2% during the forecast period.

The global metal cutting machine market growth is expected to be driven by Europe. It is currently the world’s highest revenue-generating market due to the presence of major players and the increasing adoption of Industry 4.0.

The global metal cutting machine market is dominated by players like TRUMPF, AMADA Co. Ltd., ESAB Corporation, Bystronic Laser AG, WARDJet, Koike Aronson, Inc., Nissan Tanaka Corporation, Lincoln Electric Company, Water Jet Sweden AB, Flow International Corporation, Coherent Corp., Messer Cutting Systems GmbH, Omax Corporation, Boye Laser Applied Technology Co., Ltd. and Han's Laser Technology Industry Group Co., Ltd. among others.

The metal cutting machine market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed