Polyolefin Catalyst Market Size, Share, Global Trends, Forecast to 2032

Polyolefin Catalyst Market - By Type (Metallocene, Ziegler Natta, and Peroxide Initiators), By End-User (Packaging, Pharmaceutical, Coatings, Automobile, and Construction), and By Region: Global Industry Perspective, Market Size, Statistical Research, Market Intelligence, Comprehensive Analysis, Historical Trends, and Forecasts, 2024-2032

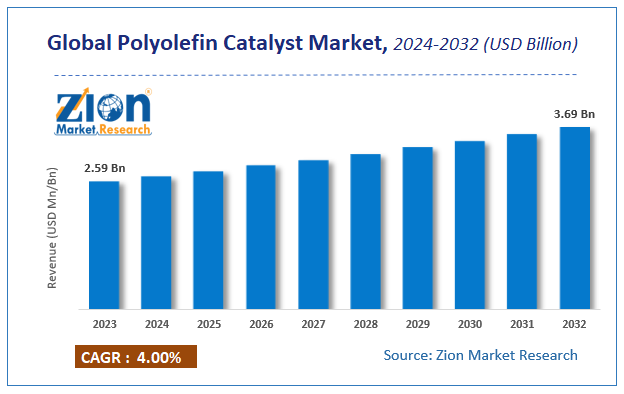

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.59 Billion | USD 3.69 Billion | 4% | 2023 |

Global Polyolefin Catalyst Market Insights

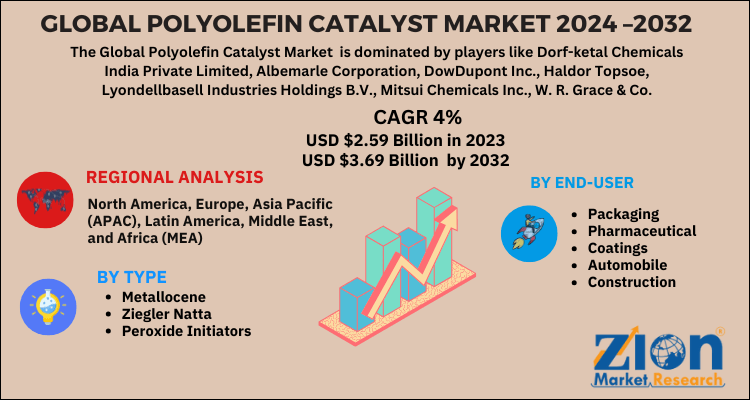

Zion Market Research has published a report on the global Polyolefin Catalyst Market, estimating its value at USD 2.59 Billion in 2023, with projections indicating that it will reach USD 3.69 Billion by 2032. The market is expected to expand at a compound annual growth rate (CAGR) of 4% over the forecast period 2024-2032.

The report explores the factors fueling market growth, the hitches that could hamper this expansion, and the opportunities that may arise in the Polyolefin Catalyst industry. Additionally, it offers a detailed analysis of how these elements will affect market demand dynamics and market performance throughout the forecast period.

Most polyolefin are made by treating the monomer with metal-containing catalysts. Polyolefin is a polymer made mostly from alkene monomers. The majority of polyolefins are produced on a big scale in an industrial setting. The Ziegler-Natta catalyst, chromium-based catalyst, metallocene single site catalyst, and post metallocene SSC are the four types of polyolefin catalysts. One of the main factors driving demand for polyolefin catalysts is the growing use of polyolefin in the food packaging industry.

Since the last decade, there has been a huge increase in demand for consumer products, owing to the fast-growing population. The market is primarily driven by an increase in demand for plastic films, goods, and packaging materials. Furthermore, technological advancements in the fluid catalytic cracking unit, which is increasing polyolefin production, are expected to boost market growth.

Polyolefin polymerization employing Ziegler-Natta catalysts has made polyolefin one of the most widely used polymers in industry. Catalysis has traditionally relied on polyethylene, polypropylene, and ethylene propylene diene monomer (EPDM) rubber. The Food Packaging Film industry’s fast expansion has increased demand for polyolefin catalysts, boosting overall market growth. In addition, increased R&D investment on new manufacturing technologies, along with capacity expansion for polyolefin plants, would also boost product demand in the coming years. Moreover, the growing automotive and packaging industries are projected to have a significant impact on the polyolefin catalyst market over the forecast period.

This report analyzes and estimates the polyolefin catalyst market at global, regional, and country level. The research study provides historic data from 2018 to 2022 along with the forecast from 2024-2032 based on revenue (USD Billion). The report offers detailed insights of the polyolefin catalyst market drivers and restraints along with their impact analysis at a global level from 2024-2032.

The report covers an in-depth analysis of the strategies adopted by major competitors in the global polyolefin catalyst market. To understand the competitive landscape in the polyolefin catalyst market, an analysis of Porter’s Five Forces model is also included. The research study comprises of market attractiveness analysis, wherein all the segments are benchmarked on the basis of their market size and growth rate.

Furthermore, the implementation of strict pollution control requirements on automobiles encourages automakers to adopt lightweight, strong, and adaptable materials in their production. This trend has resulted in a considerable increase in the demand for polyolefin materials in automotive parts, as well as an increase in the demand for polyolefin catalysts.

In emerging economies, consumer demand is fast expanding. In addition, technological advancements have increased demand for plastic films, packaged items, and construction materials. High severity fluid catalytic cracking units, for example, have enhanced yield by 27 percent to 28 percent when linked with an olefin conversion unit, and by about five times when combined with fluid catalytic cracking.

Over the study period, the development of new-generation catalyst for improving the polymerization process will also favorably contribute to the polyolefin catalyst market share. India, China, and Brazil are predicted to drive development in polyolefin goods and materials consumption, while Japan is expected to be a prominent market, owing to its developed economy and high polymer consumption.

The research study provides a decisive view on the global polyolefin catalyst market based on type, end-user, and region. All the segments of the market have been analyzed based on the past, present, and future trends. The market is estimated from 2024-2032

Polyolefin is a long chain of olefin monomers bonded covalently to form a sheet. Polyethylene is also a type of polyolefin formed through the covalent bonding between olefin ethylene monomers. Based on the extent of crystallization and molecular weight, the applications of polyolefin are determined.

Developing countries are witnessing rising demand for consumer goods, which involve the chief utilization of plastic films. Therefore, the global polyolefin catalyst market is flourishing considerably. Owing to the technological advancements in the products and production mechanisms used in the polyolefin catalyst market, the demand for packaged goods, plastic films, and construction materials has hiked.

Polyolefin catalysts serve as boosters for the production of polypropylene and polyethylene, the two major polyolefin products from crude oils. Thus, volatility in the crude oil market is eventually going to hamper the polyolefin catalyst market.

Global Polyolefin Catalyst Market Segmentation

The global polyolefin catalyst market is segmented on the basis of type, end-user, and region. All the segments have been analyzed based on present and future trends and the market is estimated from 2024 to 2032.

By type, the global industry is categorized into metallocene, Ziegler Natta, and peroxide initiators.

Based on the end-user segment, the global market is bifurcated into packaging, pharmaceutical, coatings, automobile, and construction.

The regional segmentation comprises the past, present, and estimated demand for the Middle East & Africa, North America, Asia Pacific, Latin America, and Europe. The regional segment is further split into the U.S., Canada, Mexico, UK, France, Germany, China, Japan, India, South Korea, Brazil, and Argentina among others.

Polyolefin Catalyst Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Polyolefin Catalyst Market |

| Market Size in 2023 | USD 2.59 Billion |

| Market Forecast in 2032 | USD 3.69 Billion |

| Growth Rate | CAGR of 4% |

| Number of Pages | 110 |

| Key Companies Covered | Dorf-ketal Chemicals India Private Limited, Albemarle Corporation, DowDupont Inc., Haldor Topsoe, Lyondellbasell Industries Holdings B.V., Mitsui Chemicals Inc., W. R. Grace & Co., Chicago Bridge & Iron Company N.V, Ineos Technologies Limited, Nova Chemicals Corporation, Akzo Nobel, Evonik Industries AG, China Petrochemical Corporation, Johnson Matthey, and Clariant AG. and among others |

| Segments Covered | By Type, By End-User And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Some of the leading players in the global market include

- Dorf-ketal Chemicals India Private Limited

- Albemarle Corporation

- DowDupont Inc.

- Haldor Topsoe

- Lyondellbasell Industries Holdings B.V.

- Mitsui Chemicals Inc.

- W. R. Grace & Co.

- Chicago Bridge & Iron Company N.V

- Ineos Technologies Limited

- Nova Chemicals Corporation

- Akzo Nobel

- Evonik Industries AG

- China Petrochemical Corporation

- Johnson Matthey

- Clariant AG.

The global polyolefin catalyst market is segmented as:

By Type Segmentation Analysis

- Metallocene

- Ziegler Natta

- Peroxide Initiators

By End-User Segmentation Analysis

- Packaging

- Pharmaceutical

- Coatings

- Automobile

- Construction

By Regional Segmentation Analysis

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The Polyolefin Catalyst Market was valued at USD 2.59 Billion in 2023.

The Polyolefin Catalyst Market is expected to reach USD 3.69 Billion by 2032, growing at a CAGR of of 4% between 2024 to 2032.

Polyolefin Catalyst Market players such as Dorf-ketal Chemicals India Private Limited, Albemarle Corporation, DowDupont Inc., Haldor Topsoe, Lyondellbasell Industries Holdings B.V., Mitsui Chemicals Inc., W. R. Grace & Co., Chicago Bridge & Iron Company N.V, Ineos Technologies Limited, Nova Chemicals Corporation, Akzo Nobel, Evonik Industries AG, China Petrochemical Corporation, Johnson Matthey, and Clariant AG. and among others.

Polyolefin polymerization employing Ziegler-Natta catalysts has made polyolefin one of the most widely used polymers in industry. Catalysis has traditionally relied on polyethylene, polypropylene, and ethylene propylene diene monomer (EPDM) rubber. The Food Packaging Film industry’s fast expansion has increased demand for polyolefin catalysts, boosting overall market growth. In addition, increased R&D investment on new manufacturing technologies, along with capacity expansion for polyolefin plants, would also boost product demand in the coming years.

The Regional segment includes the current and forecast demand for North America, Europe, Asia Pacific, Latin America, and the Middle East and Africa.

Choose License Type

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed