Sheet-Molding Compound and Bulk-Molding Compound Market Size, Growth and Forecast 2032

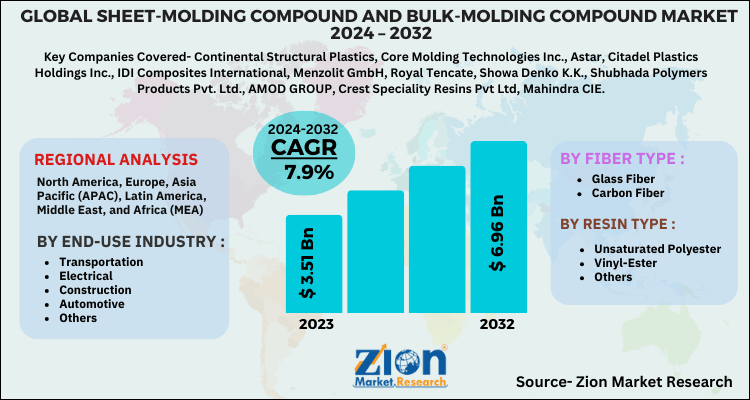

Sheet-Molding Compound and Bulk-Molding Compound Market By Fiber Type (Glass Fiber, Carbon Fiber), By Resin Type (Unsaturated Polyester, Vinyl-Ester, and Others), By End-Use Industry (Transportation, Electrical, Construction, Automotive, and Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024-2032

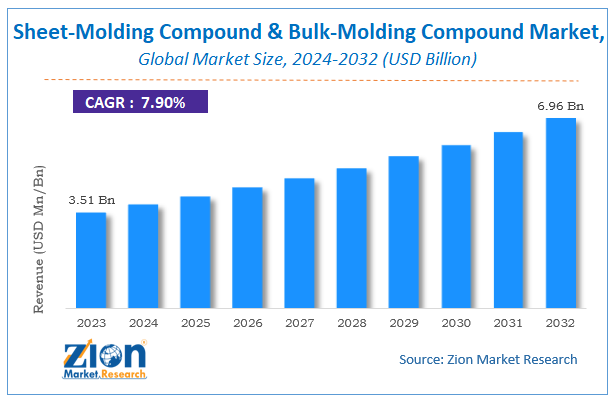

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 3.51 Billion | USD 6.96 Billion | 7.9% | 2023 |

Sheet-Molding Compound and Bulk-Molding Compound Market Insights

According to a report from Zion Market Research, the global Sheet-Molding Compound and Bulk-Molding Compound Market was valued at USD 3.51 Billion in 2023 and is projected to hit USD 6.96 Billion by 2032, with a compound annual growth rate (CAGR) of 7.9% during the forecast period 2024-2032.

This report explores market strengths, weakness, opportunities, and threats. It also provides valuable insights into the market's growth drivers, challenges, and the future prospects that may emerge in the Sheet-Molding Compound and Bulk-Molding Compound Market industry over the next decade.

Market Overview

Sheet-molding compounds (SMC) are used in various applications in the automotive sector such as hoods, deck-lids, bonnets, front ends, and spoilers. However, bulk-molding compounds (BMC) are used in several automotive parts such as ignition parts, headlight liners, and valve covers. Sheet-molding compounds and bulk-molding compounds offer immense superior features compared to other traditional compounds, which are made up of iron and steel. These compounds are highly demanding in the automotive sector for fuel-efficient vehicles.

COVID-19 Impact Analysis

The Sheet molding compound & bulk molding compound industry is anticipated to witness slow growth during the forecast period due to the ongoing global pandemic of COVID-19. The government has imposed strict lockdown protocols along with social distancing mandates in order to curb the community spreading of the COVID-19, which directly affected the manufacturing of Sheet molding compound & bulk molding compound. However, the business outlook is projected to improve with release of vaccination drives conducted globally which will bring normal situations to the manufacturing abilities thus improving the industry statistics of Sheet molding compound & bulk molding compound market in the near future.

Growth Factors

The global market is experiencing higher growth owing to increasing automation, integration of entire value chain of the process industries, and technological advancements. Moreover, growth in the transportation industry is anticipated to fuel the global sheet-molding compound and bulk-molding compound market growth in the future. Increasing urbanization further enhances the global market. The sheet-molding compound and bulk-molding compounds are highly utilized in the transportation application due to properties such as lightweight and good mechanics. Moreover, the escalating demand for fuel-efficient vehicles also acts as a crucial component in the growth of the global sheet-molding compound and bulk-molding compound market. These compounds comprise properties such as good electrical insulation, high corrosion resistance, fire & flame resistance, and high strength and rigidity, which provide ample growth opportunities in the global sheet-molding compound and bulk-molding compound market. Increasing consumer awareness regarding the flow control and growth in urbanization may propel the global market growth in the next few years.

Sheet Molding Compound (SMC) is a compression molding compound often used for larger parts where higher mechanical strength is needed. SMC is a fiber reinforced thermoset material. Customized modifications available in the market also help to boost the market. Sheet molding compounds can be molded into complex shapes. Superior mechanical properties and surface appearance, plus excellent electrical insulation make this thermoset material ideal for automotive Class A body panels, high-strength electrical parts, business equipment cabinets, personal watercraft, and various structural components are few examples of sheet and bulk molding compound.

Sheet-Molding Compound and Bulk-Molding Compound Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Sheet-Molding Compound and Bulk-Molding Compound Market |

| Market Size in 2023 | USD 3.51 Billion |

| Market Forecast in 2032 | USD 6.96 Billion |

| Growth Rate | CAGR of 7.9% |

| Number of Pages | 150 |

| Key Companies Covered | Continental Structural Plastics, Core Molding Technologies Inc., Astar, Citadel Plastics Holdings Inc., IDI Composites International, Menzolit GmbH, Royal Tencate, Showa Denko K.K., Shubhada Polymers Products Pvt. Ltd., AMOD GROUP, Crest Speciality Resins Pvt Ltd, Mahindra CIE |

| Segments Covered | By Fiber Type, By Resin Type, By end-user, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

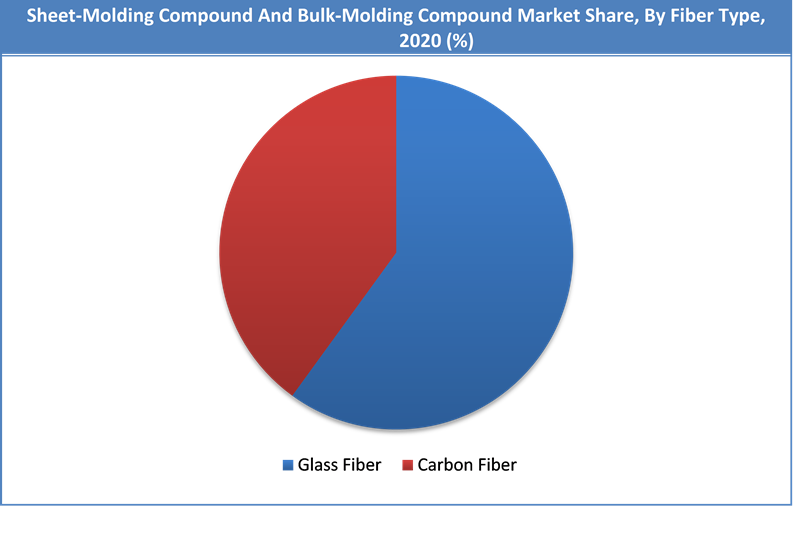

Fiber Type Segment Analysis Preview

The Sheet molding compound & bulk molding compound market has been segmented, by fiber type, as glass fiber and carbon fiber. This segmentation is based on the nature of the application in which the SMC or BMC is being used. A basic SMC Compound comprises of 60% market share and is mostly of glass fiber and is used in industry, on the other hand carbon fiber is difficult to process and expensive hence used less in industry. The nature of this impacts the applications in which it is being used and also the kind of users that are implementing the same.

End Use Industry Segment Analysis Preview

Sheet molding compound & bulk molding compound are used widely across industries. The market has been segmented, by end-user, into Transportation, Electrical, Construction, Automotive, Others. The Automotive and Electrical segment dominated the market in 2018 and is expected to grow the Sheet molding compound & bulk molding compound market during the forecast period. This is primarily because these SMC & BMC Compounds are widely used in automotive industry such as in hood parts, bonnet parts, bumpers of bus, trunks and various other applications. Similarly SMC & BMC are used in electrical industry as transformer insulation materials made up of epoxy, and glass fiber reinforced polymer. SMC and BMC compounds are cost-effective and are preferred for the various other applications.

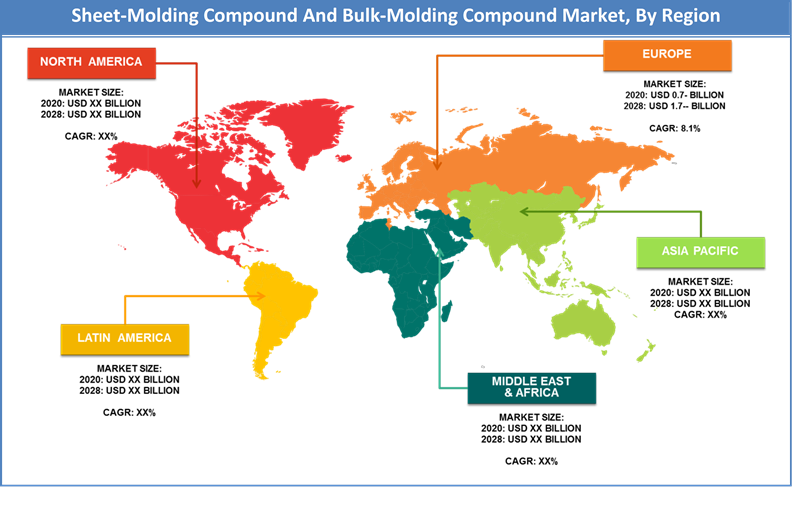

Regional Analysis Preview

Asia Pacific dominated the global Sheet molding compound & bulk molding compound market in 2018 because the region comprises relatively developing countries that require cost-effective manufacturing facilities and low labor cost. The automotive sectors, along with the other sector, proved to be the major consumers of these Sheet molding compound & bulk molding compound. The Asia Pacific region is expected to grow the market during the forecast period. China, Singapore, South Korea, Japan, and India are considered the main industrial hubs and offer tremendous growth opportunities for the Sheet molding compound & bulk molding compound market in this region.

The market for SMC and BMC in the Middle East within the rest of the world region is expected to grow with the highest CAGR during the forecast period. The growth of the transportation and electrical & electronics industries has led to increase in demand for SMC and BMC.

Key Market Players & Competitive Landscape

Some of key players in Sheet-Molding Compound And Bulk-Molding Compound market are-

- Continental Structural Plastics

- Core Molding Technologies Inc.

- Astar

- Citadel Plastics Holdings Inc.

- IDI Composites International

- Menzolit GmbH

- Royal Tencate

- Showa Denko K.K.

- Shubhada Polymers Products Pvt. Ltd.

- AMOD GROUP

- Crest Speciality Resins Pvt Ltd

- Mahindra CIE

- among others.

There are few of the recent trends and developments in the past few years.

In April 18, 2016, IDI Composites International announced today they have entered into a joint venture agreement with SMC Composites in Mexico City, Mexico. The newly named company, IDI Composites International Mexico, will focus on expanding IDI’s worldwide footprint and bring the number of IDI’s global manufacturing facilities to seven. Demand for IDI’s proven line of Sheet Molding Compounds (SMC) and Bulk Molding Compounds (BMC) is at an all-time high and IDI’s newest product line, Structural Thermoset Composites (STC®), is meeting the need for more advanced and higher performing materials in applications requiring high strength and low density. IDI recently completed a multi-million dollar expansion and upgrade of their Noblesville (USA) manufacturing facility and corporate headquarters.

The Sheet-Molding Compound And Bulk-Molding Compound market is segmented as follows:

By Fiber Type

- Glass Fiber

- Carbon Fiber

By Resin Type

- Unsaturated Polyester

- Vinyl-Ester

- Others

By End-Use Industry

- Transportation

- Electrical

- Construction

- Automotive

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Sheet-Molding Compound and Bulk-Molding Compound Market size worth at USD 3.51 Billion in 2023

Sheet-Molding Compound and Bulk-Molding Compound Market size worth at USD 3.51 Billion in 2023 and projected to USD 6.96 Billion by 2032

What are the key factors driving the Sheet-Molding Compound And Bulk-Molding Compound market growth?

The global market is experiencing higher growth owing to increasing automation, integration of entire value chain of the process industries, and technological advancements. Moreover, growth in the transportation industry is anticipated to fuel the global sheet-molding compound and bulk-molding compound market growth in the future. Increasing urbanization further enhances the global market. The sheet-molding compound and bulk-molding compounds are highly utilized in the transportation application due to properties such as lightweight and good mechanics.

Asia Pacific dominated the global Sheet molding compound & bulk molding compound market in 2018 because the region comprises relatively developing countries that require cost-effective manufacturing facilities and low labor cost.

Some of the major companies operating in the Sheet-Molding Compound And Bulk-Molding Compound market are Continental Structural Plastics, Core Molding Technologies Inc., Astar, Citadel Plastics Holdings Inc., IDI Composites International, Menzolit GmbH, Royal Tencate, Showa Denko K.K., Shubhada Polymers Products Pvt. Ltd., AMOD GROUP, Crest Speciality Resins Pvt Ltd, Mahindra CIE and among others.

Choose License Type

List of Contents

Market InsightsMarket Overview COVID-19 Impact Analysis Growth FactorsReport ScopeFiber Type Segment Analysis PreviewEnd Use Industry Segment Analysis PreviewRegional Analysis Preview Key Market Players Competitive LandscapeThe Sheet-Molding Compound And Bulk-Molding Compound market is segmented as follows:By Fiber TypeBy Resin TypeBy End-Use IndustryBy RegionRelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed