Wagon Tipplers Market Size Report, Global Industry Share, Analysis, Growth, 2030

Wagon Tipplers Market By Type (Mini Wagon Tippler and Large Wagon Tippler), By Application (Mining, Construction, Metallurgy, and Others) and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

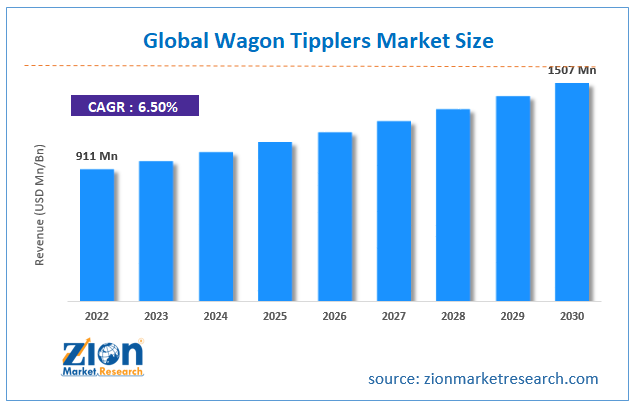

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 911 Million | USD 1507 Million | 6.5% | 2022 |

Wagon Tipplers Industry Prospective:

The global wagon tipplers market size was worth around USD 911 million in 2022 and is predicted to grow to around USD 1507 million by 2030 with a compound annual growth rate (CAGR) of roughly 6.5% between 2023 and 2030.

The report analyzes the global wagon tipplers market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the wagon tipplers industry.

Wagon Tipplers Market: Overview

A wagon tippler, also known as a railcar dumper or car dumper, is a mechanical device used in material handling systems to unload bulk materials, such as coal, ore, or aggregates, from railway wagons or railcars. It is primarily used in industries like mining, power generation, steel, cement, and ports where large quantities of materials need to be transported and unloaded efficiently. It consists of a platform or structure that can rotate or tilt to one side. The railway wagon or railcar is positioned on the tippler platform, and the tipping process is initiated. The platform rotates or tilts, causing the wagon to be overturned or tipped to discharge its contents onto a conveyor system or other transportation medium.

They are designed to handle various types of railcars, such as open-top hopper cars or gondola cars. They are often equipped with mechanisms to grip and secure the railcar during the tipping process to ensure stability and safety. The tipping operation can be manual or automated, depending on the level of sophistication and the specific requirements of the application. Automated wagon tipplers are becoming more prevalent, offering advantages such as increased productivity, reduced labor requirements, and improved operational safety. Wagon tipplers play a vital role in facilitating the efficient unloading of bulk materials from railcars, enabling further processing, storage, or transportation within the industrial facility. They are integral components of material handling systems, contributing to the overall efficiency and productivity of industries that rely on the transportation and handling of large volumes of bulk materials.

Key Insights

- As per the analysis shared by our research analyst, the global wagon tipplers market is estimated to grow annually at a CAGR of around 6.5% over the forecast period (2023-2030).

- In terms of revenue, the global wagon tipplers market size was valued at around USD 911 million in 2022 and is projected to reach USD 1507 million, by 2030.

- The growing construction industry across the globe is expected to drive the growth of the wagon tipplers market over the forecast period.

- Based on the type, the mini wagon tippler segment is expected to grow significantly during the forecast period.

- Based on region, the Asia Pacific is expected to dominate the market over the forecast period.

Wagon Tipplers Market: Growth Drivers

Growing industrialization and infrastructure development drive the market growth

The increasing industrialization and infrastructure development in emerging economies are driving the demand for wagon tipplers. Industries such as mining, power generation, steel, cement, and ports require efficient and automated material handling systems to handle bulk materials. Wagon tipplers provide a reliable solution for unloading materials from railcars, supporting the growth of these industries. For instance, according to India Brand Equity Foundation (IBEF), India produced more than 7% of the world's installed capacity for cement production, placing it as the second largest producer in the world. 98% of the total capacity is held by the private sector, while the remaining 2% is held by the governmental sector. About 70% of India's total cement production is accounted for by the top 20 businesses. India has extensive limestone reserves of excellent quality and quantity, which offers the cement sector tremendous expansion potential. Between FY16 and FY22, India's cement output is anticipated to rise at a CAGR of 5.65%, driven by demand from the construction of roads, urban infrastructure, and commercial real estate. India's cement consumption is anticipated to increase at a CAGR of 5.68% between FY16 and FY22. Thus, the growing industrialization and infrastructure development are expected to rise the demand for wagon tipplers market over the forecast period.

Wagon Tipplers Market: Restraints

Maintenance and operational costs limit the market growth

Wagon tipplers, like any mechanical equipment, require regular maintenance and upkeep. The maintenance costs can add up over the equipment's lifecycle, including routine inspections, repairs, and parts replacements. Additionally, operational costs such as energy consumption and personnel training can also impact the overall cost of owning and operating wagon tipplers. Thus, the maintenance and operational costs are expected to hamper the growth of the wagon tipplers industry over the forecast period.

Wagon Tipplers Market: Opportunities

Automation and technological advancements offer a lucrative opportunity for the market growth

Automation is a significant driver in the wagon tippler industry. Automated wagon tipplers offer benefits such as increased efficiency, reduced labor requirements, and improved safety. Integration of advanced technologies, such as sensors, actuators, and control systems, enhances the performance and productivity of wagon tipplers. The use of remote monitoring and control systems allows operators to manage tippling operations from a centralized location, further driving the market. For instance, in July 2021, the cutting-edge steel factory in Odisha's Jajpur District, Tata Steel Kalinganagar, added a new robotic technology to its Wagon Tippler operation. The Raw-Material Handling System of the steel plant's tippling processes entails crucial physical intervention at the inhaul and outhaul sides for the coupling, decoupling, rotation, and CBC alignment of wagons. Therefore, this type of technological advancement is expected to provide an enormous opportunity for market growth over the forecast period.

Wagon Tipplers Market: Challenges

High initial investment costs pose a major challenge

The implementation of wagon tipplers requires a significant upfront investment. The cost includes not only the equipment itself but also installation, infrastructure modifications, and integration with existing systems. The high capital expenditure can be a restraint for the wagon tipplers market, especially for smaller or financially constrained organizations, limiting their ability to adopt wagon tippler technology.

Wagon Tipplers Market: Segmentation

The global wagon tipplers industry is segmented based on type, application, and region.

Based on the type, the global market is bifurcated into mini wagon tippler and large wagon tippler. The mini wagon tippler segment is expected to grow significantly during the forecast period. Small wagon tippers are called mini tippers. These tipplers are used in smaller-scale sectors like steel production and power plants to handle coal. Payloads up to 500 kg can be handled by the small wagon tippler. The device can handle full wagon tipplers in two or three minutes and is designed to run on a sidearm charger. On the other hand, the large wagon tippler segment is expected to capture the largest market share over the projected period. The growth in the segment is attributed to the increasing mining and construction industry. A wagon tipper that can carry heavier cargo is called a Large Wagon Tippler (Payload > 1000 kg). When handling enormous amounts of material swiftly and easily, these wagon tipplers are employed in the mining and construction industries. They are capable of carrying weights up to 1500 kg or greater. Therefore, these wagon tipplers are perfect for use in the mining, building, and metallurgical industries.

Based on the application, the global wagon tipplers industry is bifurcated into mining, construction, metallurgy, and others.

Recent Developments:

- In January 2023, the Indian Railways intends to implement several wagon tipplers to accelerate the country's coal distribution system. The railways are aiming to build more wagon tipplers as well as more wagon unloading lines to empty the coal wagons at the power plants. With the use of clamping tools, coal wagon tipplers are used to empty the laden wagons from the top and sides. The Indian Railways now employ one wagon tippler to remove coal. Railways anticipate quick coal flow and a decrease in travel time with the rise of wagon tippers.

Wagon Tipplers Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Wagon Tipplers Market Report |

| Market Size in 2022 | USD 911 Million |

| Market Forecast in 2030 | USD 1507 Million |

| Growth Rate | CAGR of 6.5% |

| Number of Pages | 223 |

| Key Companies Covered | Elecon Engineering Company Limited, ThyssenKrupp Industries India Pvt. Ltd., AUMUND GROUP, Metso, TEHNOROS, Promac Engineering Industries Limited, FLSmidth, Heyl & Patterson, Altra, LMM Group, TRF Limited, TENOVA, Avery Weigh-Tronix and Elecon Tipplers among others. |

| Segments Covered | By Type, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Wagon Tipplers Market: Regional Analysis

The Asia Pacific is expected to dominate the market over the forecast period

The Asia Pacific is expected to dominate the global wagon tippler market over the forecast period. The regional growth is attributed to the increasing construction industry, especially in the countries like India, China, and others. China is now experiencing a tremendous manufacturing boom. With 20% of all global construction investments, the country has the largest construction market in the world. And it will continue to increase: by 2030, China is predicted to spend close to USD 13 trillion on construction. Due to COVID-19's effects as the developer market's cash flow increased, investments were reduced. Large swings in retail activity affected both developed projects and commercial enterprises, rental revenue dropped, and companies reduced office space to cut down on leasing expenses. The value of newly signed contracts in the construction sector in 2021 was USD 19.52 billion, up 2.5% year over year, and the growth rate was 7.1% points slower than it was during the same period in the previous year. China announced intentions to grow its construction sector in January 2022 as part of the 14th Five-Year Plan (2021-2025), putting one of the cornerstones of the economy on a greener, smarter, and safer route. Thus, the aforementioned facts support the market growth in the region during the forecast period.

Wagon Tipplers Market: Competitive Analysis

The global wagon tipplers market is dominated by players like:

- Elecon Engineering Company Limited

- ThyssenKrupp Industries India Pvt. Ltd.

- AUMUND GROUP

- Metso

- TEHNOROS

- Promac Engineering Industries Limited

- FLSmidth

- Heyl & Patterson

- Altra

- LMM Group

- TRF Limited

- TENOVA

- Avery Weigh-Tronix

- Elecon Tipplers

- Others.

The global wagon tipplers market is segmented as follows:

By Type

- Mini Wagon Tippler

- Large Wagon Tippler

By Application

- Mining

- Construction

- Metallurgy

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

For the transportation of the raw materials, wagon tipplers are used. The main end-use industries where the wagon tipplers are used include construction and mining. With the help of electro-mechanical drive or the hydraulic drive wagon tipplers are driven. The wagon tipplers are categorized as C-frame rotary tipplers or turnover wagon tipplers. During the operation, for reducing the depth of the receiving foundation the tipplers lift the wagon. In the industries, the usage of wagon tipplers is depended on the material type and their property. The wagon tippler consists of eight components which include end rings, platen assembly, counterweight, clamp assembly, spill truss, wheel chocks, wheel grippers, and drive units.

The market growth of wagon tipplers in many regions is due to the development of end-use industries such as mining, construction, demolition, aggregate, industrial, environmental, etc. Increasing concerns by the industries regarding safety and efficiency during the transportation and the handling of the products have globally increased the demand for wagon tipplers. Many operational benefits are provided by the wagon tipplers which is helpful in various industries thus propelling the demand for the global wagon tipplers market.

According to the report, the global wagon tippler market size was worth around USD 911 million in 2022 and is predicted to grow to around USD 1507 million by 2030.

The global wagon tipplers market is expected to grow at a CAGR of 6.5% during the forecast period.

The global wagon tipplers market growth is expected to be driven by the Asia Pacific. It is currently the world’s highest revenue-generating market owing to the growing mining industry, especially in the countries like China, Australia, and others.

The global wagon tipplers market is dominated by players like Elecon Engineering Company Limited, ThyssenKrupp Industries India Pvt. Ltd., AUMUND GROUP, Metso, TEHNOROS, Promac Engineering Industries Limited, FLSmidth, Heyl & Patterson, Altra, LMM Group, TRF Limited, TENOVA, Avery Weigh-Tronix and Elecon Tipplers among others.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed