Alloy Steel Market Size, Share, Trends, Growth 2030

Alloy Steel Market By Applications (Automotive, Agriculture, Construction, Aerospace, Mining, and Others), By Product (High-Alloy Steel and Low-Alloy Steel), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

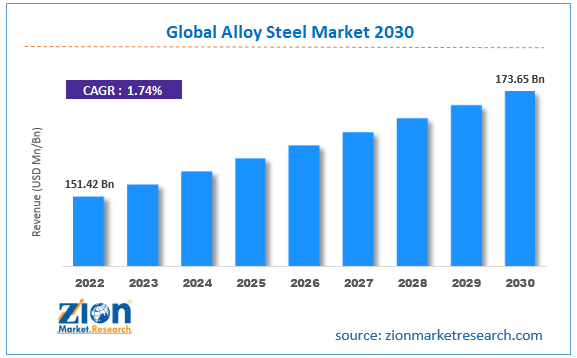

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 151.42 Billion | USD 173.65 Billion | 1.74% | 2022 |

Alloy Steel Industry Prospective:

The global alloy steel market size was worth around USD 151.42 billion in 2022 and is predicted to grow to around USD 173.65 billion by 2030 with a compound annual growth rate (CAGR) of roughly 1.74% between 2023 and 2030.

Alloy Steel Market: Overview

Alloy steel is a type of steel produced by combining one or more elements with conventional steel. The materials used in combination are known as alloying elements and they help in increasing the overall performance, chemical, thermal, and physical properties of products made using alloy steel. These elements have the ability to impact factors such as hardness, strength, toughness, and resistance of conventional steep, thus allowing the production of substantive and robust variants. Several options are available as alloying material thus providing customers with a wider range of end options when choosing the alloy steel material. Some of the most commonly used materials as alloys are chromium, manganese, nickel, vanadium, and tungsten. Each alloy has specific properties and production requirements. For instance, manganese is typically used in combination with small amounts of phosphorus and sulfur to make alloy steel easier to hammer and less brittle. On the other hand, tungsten boosts resistance to heat thus contributing to the overall structural makeup of alloy steel.

Key Insights:

- As per the analysis shared by our research analyst, the global alloy steel market is estimated to grow annually at a CAGR of around 1.74% over the forecast period (2023-2030)

- In terms of revenue, the global alloy steel market size was valued at around USD 151.42 billion in 2022 and is projected to reach USD 173.65 billion, by 2030.

- The alloy steel market is projected to grow at a significant rate due to the rising applications in the automobile sector

- Based on application segmentation, construction was predicted to show maximum market share in the year 2022

- Based on product segmentation, the low-steel alloy was the leading segment in 2022

- On the basis of region, Asia-Pacific was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Alloy Steel Market: Growth Drivers

Rising applications in the automobile sector to drive market growth

The global alloy steel market is expected to grow due to the increasing applications of engineered steel in the growing automobile industry. This trend is especially applicable to steel variants consisting of chromium, nickel, or a combination of both. Automobile companies have shown special interest in alloy steel containing up to approximately 1.5 % chromium and 5% nickel with carbon content ranging between 0.1 to 0.5%. These quantities ensure that metallographic constituents of the steel are retained while physical properties are improved for higher applications.

High-strength low alloy steels have shown exceptional performance facilitating the production of heavy parts of an automotive vehicle such as cylinder heads, crankshafts, and camshafts. While alloy steel ensures performance efficiency they are also relatively more cost-effective further driving its popularity in the automobile industry. Factors such as rising demand for affordable vehicles, growing investments in public transport infrastructure, higher accessibility to financial assistance, rising disposable income, and availability of a range of automotive including 2-wheelers, 3-wheelers, and 4-wheelers for personal use are some of the most significant revenue-affecting factors for the global automotive market.

In addition to these developments, the growing consumer segment for electric and hybrid vehicles is projected to have a drastic impact on the demand for alloy steel since electric vehicle (EV) manufacturers are focusing on providing lightweight and high-performance vehicles. A growing number of EV providers and increasing consumer awareness about the benefits of EVs will lead to demand in the electric vehicle industry in turn propelling the consumption of alloy steel.

Alloy Steel Market: Restraints

Growing competition from alternate solutions to restrict market growth

The global alloy steel market growth is expected to be limited due to the increasing popularity and demand for alternate solutions especially the consumption of carbon steel. Research indicates that alloy steel is more difficult to weld in comparison to carbon steel. On the other hand, they are also more expensive in terms of production and have a higher susceptibility to corrosion in comparison to their counterpart. These factors have resulted in more buyers shifting toward affordable and easy-to-work-with solutions. In addition to this, while steel products do not pose any harm when in contact, activities such as sawing, welding, grinding, and burning of alloy steel could lead to exposure to harmful elements. Although these ingredients are not toxic but may lead to discomfort in human resources working with the material.

Alloy Steel Market: Opportunities

Growing research toward performance improvement and rising partnerships to create growth opportunities

The alloy steel industry players can expect higher growth opportunities due to the several development programs undertaken across the globe to improve several aspects of alloy steel production and applications. For instance, in June 2023, researchers from Purdue University in association with Sandia National Laboratories developed a new treatment that produces steel alloys with exceptional plasticity and strength. The scholars used T-91 steel alloy for the experiment. While T-91 is currently used in the petrochemical and nuclear industry, the treatment method can be used for other applications in need of ductile and strong steel such as suspension cables, car axles, and other critical structural components. The final product was modified G-T91 and its sample yield strength was recorded at 700 megapascals. In 2018, WMG, the University of Warwick, Tata Steel, and Swansea University announced they won funding from the Engineering and Physical Sciences Research Council (EPSRC) worth £7 million which the partnering entries plan to invest in integrating alloy steel physical testing with computational modeling to reduce the time taken for alloy steel production. October 2022 witnessed the start of a partnership between Mishra Dhatu Nigam Limited (MIDHANI) and Boeing India to develop raw materials for the aerospace sector. MIDHANI is a state-run supplier of steel components, superalloys, and other materials.

Alloy Steel Market: Challenges

Lengthy process for new alloy steel development may challenge further growth

The global alloy steel market growth trend may face challenges due to the lengthy process involved in the production of new alloy steel. Apart from being long, the process is slow and involves multiple stages that directly contribute to the overall complexity of the alloy steel production process. The trial process is expensive since it requires the use of large quantities of initial raw materials. Moreover, due to the sophisticated technologies involved in the production process, it should only be conducted in the presence of skilled labor to avoid mishaps. All of these factors act as significant barriers against future growth.

Alloy Steel Market: Segmentation

The global alloy steel market is segmented based on applications, product, and region.

Based on applications, the global market segments are automotive, agriculture, construction, aerospace, mining, and others. In 2022, the highest growth rate was observed in the construction segment owing to the increasing use of alloy steel for several infrastructure development projects. Alloy steel has a higher resistance to corrosion. They can also handle extreme temperatures making them ideal for the construction of pipelines in industries carrying materials at varying temperatures. On the other hand, since multiple options of alloy steel are available in the market, construction companies can customize alloy steel as per their requirements. India’s current infrastructure projects are worth 3.3% of the country's total gross domestic product.

Based on product, the alloy steel industry segments are high-alloy steel and low-alloy steel. In 2022, the demand was higher for low-alloy steel due to extensive applications in two of the fastest-growing sectors including automotive and construction industries. Low-alloy steel has a relatively lesser quantity of alloying elements as opposed to its counterpart. As per research, the total alloying content in low-alloy steel is not more than 12%. However, high-alloy steel is growing at a steady rate with increased demand for use in the expanding aerospace industry.

Alloy Steel Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Alloy Steel Market |

| Market Size in 2022 | USD 151.42 Billion |

| Market Forecast in 2030 | USD 173.65 Billion |

| Growth Rate | CAGR of 1.74 |

| Number of Pages | 221 |

| Key Companies Covered | ThyssenKrupp AG, ArcelorMittal, Outokumpu Oyj, Nippon Steel Corporation, Carpenter Technology Corporation, POSCO, AK Steel, Voestalpine AG, China Baowu Steel Group Corporation Limited, JFE Steel Corporation, Aperam, Tata Steel, SSAB AB, Sandvik AB, Allegheny Technologies Incorporated (ATI), and others. |

| Segments Covered | By Application, By Product, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Alloy Steel Market: Regional Analysis

Asia-Pacific to lead with the highest CAGR during the projected timeline

The global alloy steel market is expected to witness the highest growth in Asia-Pacific since the region is home to a robust steel-producing and distributing regional industry. China, India, Japan, and South Korea are leading producers of steel and alloy steel. In 2022, China was the world’s top-ranking steel producer with control over 54% of the global steel production. In addition to this, these regions are well-equipped with technologies and production facilities that allow them to produce bulk quantities of alloy steel. Similarly, India is witnessing increased investments in further enhancement of the regional alloy steel industry. In July 2023, the Union Steel Ministry of India announced that it was consulting industrial players to develop the country’s first stainless steel policy which aims to properly domestic production by 5 times pushing from the current 6.6 million tonnes to 30 by the end of 2047. Factors such as increasing end-user consumption, rising research and development, and expanding production facilities are expected to drive regional growth during the forecast period.

Alloy Steel Market: Competitive Analysis

The global alloy steel market is led by players like:

- ThyssenKrupp AG

- ArcelorMittal

- Outokumpu Oyj

- Nippon Steel Corporation

- Carpenter Technology Corporation

- POSCO

- AK Steel

- Voestalpine AG

- China Baowu Steel Group Corporation Limited

- JFE Steel Corporation

- Aperam

- Tata Steel

- SSAB AB

- Sandvik AB

- Allegheny Technologies Incorporated (ATI)

The global alloy steel market is segmented as follows:

By Applications

- Automotive

- Agriculture

- Construction

- Aerospace

- Mining

- Others

By Product

- High-Alloy Steel

- Low-Alloy Steel

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Alloy steel is a type of steel produced by combining one or more elements with conventional steel.

The global alloy steel market is expected to grow due to the increasing applications of engineered steel in the growing automobile industry.

According to study, the global alloy steel market size was worth around USD 151.42 billion in 2022 and is predicted to grow to around USD 173.65 billion by 2030.

The CAGR value of the alloy steel market is expected to be around 1.74% during 2023-2030.

The global alloy steel market is expected to witness the highest growth in Asia-Pacific since the region is home to a robust steel-producing and distributing regional industry.

The global alloy steel market is led by players like ThyssenKrupp AG, ArcelorMittal, Outokumpu Oyj, Nippon Steel Corporation, Carpenter Technology Corporation, POSCO, AK Steel, Voestalpine AG, China Baowu Steel Group Corporation Limited, JFE Steel Corporation, Aperam, Tata Steel, SSAB AB, Sandvik AB, and Allegheny Technologies Incorporated (ATI).

The report explores crucial aspects of the alloy steel market including detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed