Automatic Visual Inspection Systems Market Size, Share, Trends, Growth and Forecast 2030

Automatic Visual Inspection Systems Market By Industry (Industrial, Consumer Electronics, Aerospace & Defense, Telecommunications, Medical Devices, Automotive, Energy & Power, and Others), By Details (3-Dimensional and 2-Dimensional), By Application (Assembly Phase and Fabrication Phase), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

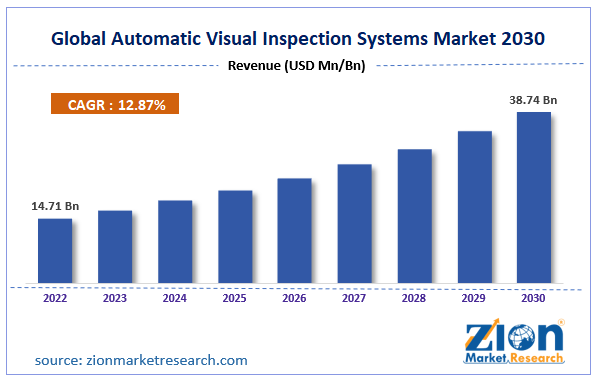

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 14.71 Billion | USD 38.74 Billion | 12.87% | 2022 |

Automatic Visual Inspection Systems Industry Prospective:

The global automatic visual inspection systems market size was worth around USD 14.71 billion in 2022 and is predicted to grow to around USD 38.74 billion by 2030 with a compound annual growth rate (CAGR) of roughly 12.87% between 2023 and 2030.

Automatic Visual Inspection Systems Market: Overview

Automatic visual inspection systems are quality control tools used across industries. They are used to ensure that product quality is not compromised before being launched in the commercial market. Automatic visual inspection systems (AVISs) have extensive applications across industries including manufacturing and automobiles. They are specifically used in industries that deal with the manufacturing of precision smaller components such as the semiconductor industry. Their core function is to act as the eyes on the production line to leverage state-of-the-art and highly advanced computer vision systems to detect any form of abnormality including contamination or deformities that may compromise the overall quality of the product.

During the manufacturing process, AVIS can be more helpful as compared to traditional manual inspection systems. Some of the key advantages of using automated visual inspection systems are the use of the technology even in dangerous or unsafe conditions, faster processing time, and higher resolution in the final optics. During the forecast period, the demand for AVIS is projected to register a high growth rate.

Key Insights:

- As per the analysis shared by our research analyst, the global automatic visual inspection systems market is estimated to grow annually at a CAGR of around 12.87% over the forecast period (2023-2030)

- In terms of revenue, the global automatic visual inspection systems market size was valued at around USD 14.71 billion in 2022 and is projected to reach USD 38.74 billion by 2030.

- The automatic visual inspection systems market is projected to grow at a significant rate due to the increasing acceptance and investments in Industry 4.0

- Based on industry segmentation, automotive was predicted to show maximum market share in the year 2022

- Based on application segmentation, the assembly phase was the leading segment in 2022

- On the basis of region, Asia-Pacific was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Automatic Visual Inspection Systems Market: Growth Drivers

Increasing acceptance and investments in Industry 4.0 may lead to higher market demand

The global automatic visual inspection systems market is expected to grow owing to the increasing investments in Industry 4.0 also known as the fourth industrial revolution. Industry 4.0 deals with integration of advanced technologies and systems to change how companies function. Businesses are actively investing in new-age tools such as artificial intelligence (AI), machine learning (ML), Internet of Things (IoT), and cloud computing to gather data information, perform business functions, and make informed decisions.

During the forecast period, the Industry 4.0 market is projected to grow at a CAGR of nearly 20%. Automation visual inspection systems provide automated and machine-powered quality check solutions. They are faster and offer wider applications as compared to manual testing.

Increasing the launch of new and advanced AVIS technologies may deliver higher revenue

The demand for automatic visual inspection systems may have positive results due to the rising launch of improved AVIS technologies offering higher performance. The changing industrial applications have created an urgent need for automatic visual inspection system developers to produce solutions that can meet modern demands.

In December 2023, a leading supplier of services and equipment optimizing semiconductor manufacturing yield and productivity, Cohu, announced the launch of a new AI Inspection software. The new launch will form a part of Cohu’s primary offerings in terms of analytics platform. The AI Inspection software will offer real-time computation and is expected to serve the expectations of semiconductor manufacturers. Such advancements improve overall performance and product application thus impacting the global automatic visual inspection systems market.

Automatic Visual Inspection Systems Market: Restraints

High cost of automated visual inspection systems may restrict the market growth rate

The global industry for automatic visual inspection systems market is projected to be restricted due to the high cost of AVIS technologies. As per market research, the total life-cycle expense of AVIS is twice the initial cost of investment due to higher maintenance charges.

Performance and operational costs of automated visual inspection systems are considered hidden which may restrict market expansion. The average cost of AVIS may range between USD 5000 to USD 20,000.

Automatic Visual Inspection Systems Market: Opportunities

Increasing application in the automobile sector may deliver high-growth opportunities

The global automatic visual inspection systems market is projected to come across growth opportunities due to the increasing use of AVIS tools in the automobile sector. There is a growing market for electric vehicles (EVs). Consumers are increasingly opting for sustainable solutions. The constantly changing fuel prices along with a rising understanding of the global impact of fuel-powered vehicles has resulted in a growing demand and use of EVs across passenger vehicles and commercial automobile segments.

Automated visual inspection systems are used for quality assurance in regard to automobile parts such as paint quality, electronic components, lighting systems, engine components, chassis inspection, assembly verification, and others. Additionally, the growing access to financial assistance coupled rising purchasing power of consumers may positively impact AVIS market demand

Growing use in the packaging industry may deliver higher growth results

The demand for automatic visual inspection systems will be driven by the increasing use of the technology in the growing packaging industry. Quality check is a crucial aspect of the packaging process where packaged goods undergo thorough checking before being stored for transportation.

AVIS technologies can automate the complete process and reduce human error or delay in the quality check process. The increasing number of packaged consumer goods in the market influenced by the growing population rate may deliver higher results.

Automatic Visual Inspection Systems Market: Challenges

Effect of automation on human employment and job displacement are key challenges to overcome

The global automatic visual inspection systems market will be challenged by the increasing concerns over automated systems replacing human labor leading to employment loss and displacement. In addition to this, training employees can become an additional issue especially if the human workforce shows hesitancy toward change. Companies adopting automated visual inspection systems must ensure that they can achieve a balance between technological resources and human skills.

Automatic Visual Inspection Systems Market: Segmentation

The global automatic visual inspection systems market is segmented based on industry, details, application, and region.

Based on industry, the global market is divided into industrial, consumer electronics, aerospace & defense, telecommunication, medical devices, automotive, energy & power, and others. In 2022, the highest growth was observed in the automotive segment. The primary reason for growth is the increasing use of AVIS technologies on assembly lines for all automobile components including the paint used over body parts and the electrical components. The rise in automotive technological innovation may result in higher segmental growth. As per official reports, the German automotive companies collectively spent over EUR 28 billion in 2021 on research & development.

Based on details, the global automatic visual inspection systems industry is divided into 3-dimension and 2-dimensions.

Based on application, the global market segments are assembly phase and fabrication phase. In 2022, the highest demand was registered in the assembly phase due to the extensive application of the technology across industries with extensive assembly lines such as medical device production, the automotive industry, and others. The fabrication segment is growing rapidly driven by the growing market expansion in the semiconductor manufacturing industry. In 2022, the global semiconductor market was valued at USD 574 billion.

Automatic Visual Inspection Systems Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Automatic Visual Inspection Systems Market |

| Market Size in 2022 | USD 14.71 Billion |

| Market Forecast in 2030 | USD 38.74 Billion |

| Growth Rate | CAGR of 12.87% |

| Number of Pages | 206 |

| Key Companies Covered | Omron Corporation, Cognex Corporation, Teledyne Technologies Incorporated, Keyence Corporation, Baumer Inspection GmbH, National Instruments Corporation, Perceptron Inc., ISRA VISION AG, Datalogic S.p.A., Basler AG, Mettler-Toledo International Inc., Matrox Electronic Systems Ltd., Shanghai VisionTech, PPT Vision (a Division of Datalogic), SICK AG., and others. |

| Segments Covered | By Industry, By Details, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Automatic Visual Inspection Systems Market: Regional Analysis

Asia-Pacific to generate the highest CAGR during the projection period

The global automatic visual inspection systems market will be led by Asia-Pacific during the forecast period. India, China, Japan, and South Korea are some of the largest contributors to the demand for AVIS technologies. For instance, India and China are considered as the manufacturing giants of consumer goods including electronics and cosmetic items. The growing number of manufacturing facilities as well as a higher focus on quality performance may lead to regional dominance during the forecast period. In addition to this, Japan and China are leading countries in terms of automobile innovation and manufacturing. China is the largest supplier and producer of electric vehicles in the domestic and international markets.

Additionally, Asian countries have a large presence of AVIS technology developers. Europe is projected to grow rapidly over the projection period. Increased focus on quality checks and a mature acceptance of automated systems with the availability of skilled labor act as a growth foundation for Europe. North America will register a significant growth rate led by the increasing use of AVIS in the semiconductor manufacturing process. Furthermore, increased regional innovation-led investments may help North America’s growth trajectory.

Automatic Visual Inspection Systems Market: Competitive Analysis

The global automatic visual inspection systems market is led by players like:

- Omron Corporation

- Cognex Corporation

- Teledyne Technologies Incorporated

- Keyence Corporation

- Baumer Inspection GmbH

- National Instruments Corporation

- Perceptron Inc.

- ISRA VISION AG

- Datalogic S.p.A.

- Basler AG

- Mettler-Toledo International Inc.

- Matrox Electronic Systems Ltd.

- Shanghai VisionTech

- PPT Vision (a Division of Datalogic)

- SICK AG.

The global automatic visual inspection systems market is segmented as follows:

By Industry

- Industrial

- Consumer Electronics

- Aerospace & Defense

- Telecommunications

- Medical Devices

- Automotive

- Energy & Power

- Others

By Details

- 3-Dimensional

- 2-Dimensional

By Application

- Assembly Phase

- Fabrication Phase

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Automatic visual inspection systems are quality control tools used across industries.

The global automatic visual inspection systems market is expected to grow owing to the increasing investments in Industry 4.0 also known as the fourth industrial revolution.

According to study, the global automatic visual inspection systems market size was worth around USD 14.71 billion in 2022 and is predicted to grow to around USD 38.74 billion by 2030.

The CAGR value of automatic visual inspection systems market is expected to be around 12.87% during 2023-2030.

The global automatic visual inspection systems market will be led by Asia-Pacific during the forecast period.

The global automatic visual inspection systems market is led by players like Omron Corporation, Cognex Corporation, Teledyne Technologies Incorporated, Keyence Corporation, Baumer Inspection GmbH, National Instruments Corporation, Perceptron, Inc., ISRA VISION AG, Datalogic S.p.A., Basler AG, Mettler-Toledo International Inc., Matrox Electronic Systems Ltd., Shanghai VisionTech, PPT Vision (a Division of Datalogic), and SICK AG.

The report explores crucial aspects of the automatic visual inspection systems market including detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

Choose License Type

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed