Controlled Intelligent Packaging Market Size, Share, Analysis, Growth, 2032

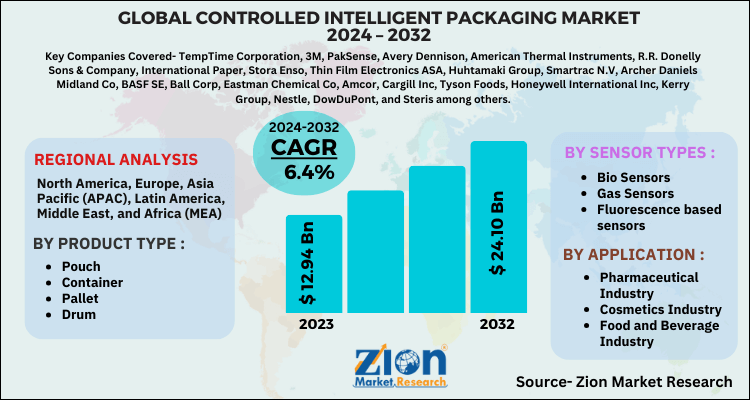

Controlled Intelligent Packaging Market By Product Type (Pouch, Container, Pallet, and), By Application (Pharmaceutical Industry, Cosmetics Industry, and Food and Beverage Industry), By Sensor Types (Bio Sensors, Gas Sensors, and Fluorescence based sensors): Global Industry Perspective, Comprehensive Analysis, and Forecast, 2024 - 2032

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 12.94 Billion | USD 24.10 Billion | 6.4% | 2023 |

Controlled Intelligent Packaging Market Insights

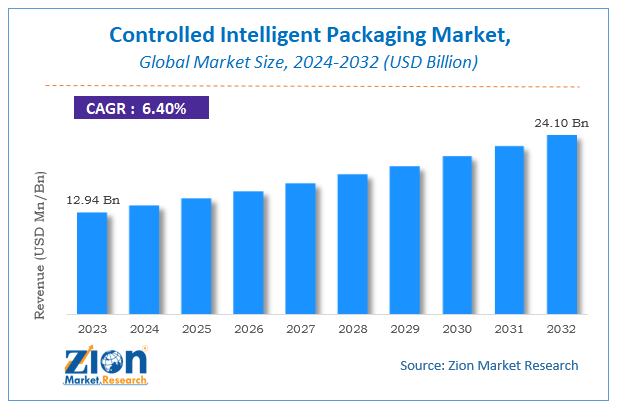

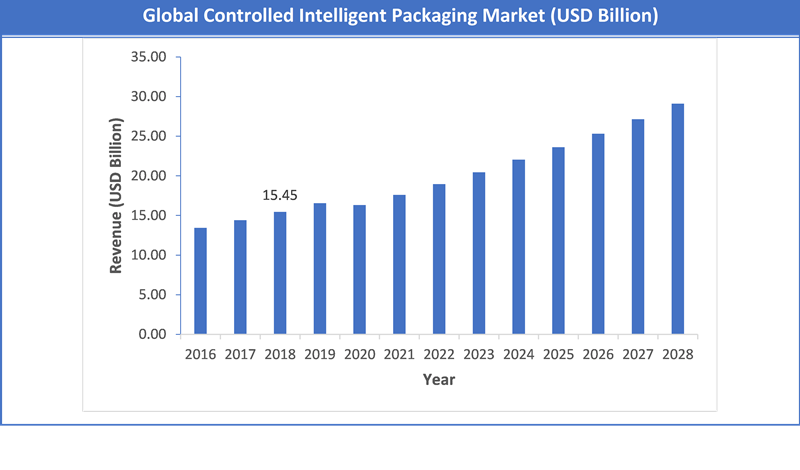

According to a report from Zion Market Research, the global Controlled Intelligent Packaging Market was valued at USD 12.94 Billion in 2023 and is projected to hit USD 24.10 Billion by 2032, with a compound annual growth rate (CAGR) of 6.4% during the forecast period 2024-2032. This report explores market strengths, weakness, opportunities, and threats. It also provides valuable insights into the market's growth drivers, challenges, and the future prospects that may emerge in the Controlled Intelligent Packaging Market industry over the next decade.

Controlled Intelligent Packaging Market: Overview

Controlled Intelligent Packaging is a type of packaging system which helps in carrying out intelligent functions such as detecting and applying a logical basis to carry out tasks such as primary detecting, sensing, recording, and communicating. The controlled intelligent packaging includes different indicators such as time-temperature indicators, integrity indicators, and freshness indicators. It serves the purpose such as making decision to extend product shelf life, helps in refining quality, delivering information improving safety and notifying regarding possible threats. It comes in various sizes and shapes and is used for marketing purposes too.

The market is primarily driven by the food and beverage industry as consumers nowadays are preferring more safe and healthy food. As the demand for the quality food products is increasing, the overall demand for the controlled intelligent packaging is increasing. Nowadays, legal frameworks are being considered for the intelligent packaging, where it is taken care that the packaging does not transfer its constituents to the food. Also, the packaging now is equipped with indicators and sensors through which the current quality status of the product can be determined. This also helps in increasing the safety of the product and unnecessary food wastage can be reduced.

COVID-19 Impact Analysis

The global impacts of Covid-19 are estimated to impact positively on the Controlled Intelligent Packaging industry. This is due to the fact that supply chains for the packaged industry are readjusting as per the new demands. Intelligent packaging is being more preferred as smartphone technology allows consumers to easily communicate through QR codes and the packaging has also proved, in this pandemic, its ability to minimize food wastage and maximize packaging recycling. Also, the rising international trade through e-commerce, which has been quite evident through the pandemic has increased the demand for smart packaging which ensures the authenticity of the goods and takes cares of good non-interfered packaging.

Controlled Intelligent Packaging Market: Growth Factors

There has been increase in demand from the consumers for the fresh and good quality food with systematic packaging, which has been a driving factor for the food and technology industry to develop the innovative and improved concepts of technology packaging. Therefore, manufacturers are constantly looking for new products with the features such as UV protection, transparency, and environmental protection. Also, due to the usage of technology, intelligent packaging has improved the efficiencies via communication and has helped for the item level tracking of the products in the factory. The usage of Nanotechnology has also helped to release new barrier and anti-microbial properties required for active packaging by designing materials at smallest level. The rising inclination to consume safe food and avowing contamination by the manufacturers has boosted the demand for Controlled Intelligent packaged food products.

Also, the rapid urbanization and the change in the lifestyle of the consumers, demands for the products such as controlled intelligent packaged foods. The demand for the self-heating and cooling packaged products for the beverages such as tea, coffee and chocolate is expected to boost the demand for the controlled intelligent packaging.

Controlled Intelligent Packaging Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Controlled Intelligent Packaging Market |

| Market Size in 2023 | USD 12.94 Billion |

| Market Forecast in 2032 | USD 24.10 Billion |

| Growth Rate | CAGR of 6.4% |

| Number of Pages | 120 |

| Key Companies Covered | TempTime Corporation, 3M, PakSense, Avery Dennison, American Thermal Instruments, R.R. Donelly Sons & Company, International Paper, Stora Enso, Thin Film Electronics ASA, Huhtamaki Group, Smartrac N.V, Archer Daniels Midland Co, BASF SE, Ball Corp, Eastman Chemical Co, Amcor, Cargill Inc, Tyson Foods, Honeywell International Inc, Kerry Group, Nestle, DowDuPont, and Steris among others |

| Segments Covered | By Product Type, By Application, By Sensor Types and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

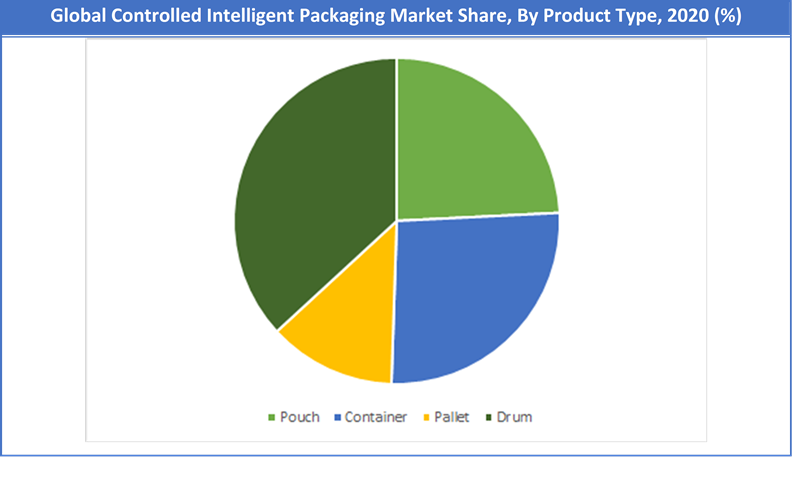

Product Type Analysis Preview

This is mainly due to its ability to provide improved product shelf life and the minimization of food waste. Consumers prefer the pouch type as it comes with the features such as sealed material with superior oxygen, moisture, and odor control. Also, these pouches are resalable and recyclable, thus contributing to a circular economy. These pouches are also preferred by the wholesalers as they support bulk packaging of fresh foods and support storage and long-haul shipments.

This is due to the fact that containers provide the facility to track using RFID sensors. This greatly helps the manufacturers to track the containers enabling optimal monitoring and traceability. The controlled intelligent packaging offers differently shaped and sized containers which is adaptable to consumers’ lifestyle.

Application Analysis Preview

Due to the factors such as product safety and connectivity, the healthcare and pharmaceutical industries have been investing a lot in the smart packaging solutions. Also, in these industries temperature and time has lot of impact on the overall condition of the drugs and medicines. So, it becomes a topmost priority to use effective and intelligent packaging systems. There has the constant demand to protect the products from the unwanted moisture and oxygen and remove the unwanted impurities, which makes the demand of controlled intelligent packaging devices even more.

The changing lifestyles of the consumers and growing demand for the fresh foods is the main reason for this growth. Also, these packaging are widely used to reduce the unintentional waste. The intelligent packaging also avails the facility to monitor and track the quality status, which protects the consumers from potential food poisoning.

Sensor Types Analysis Preview

This is mainly due to the fact that biosensors provide the facility of controlling the environment and help in product packaging. It also greatly assists in detecting pathogens in food, and detect the deteriorative changes in food packaging. Also, in the future it is predicted that these sensors can be used to trigger the controllable release of bioactive components and can be used for the delivery of protective agents into the food product.

They greatly help in controlling the toxic composition of gases that are produced due to decomposing food in the food container, which can be harmful for the consumers. Indicators are placed in direct contact with the gaseous environment surrounding the food in the container to detect any abnormalities. These gas sensors are also used to monitor the freshness or quality of food products in real time. Thus, the demand for such sensors is bound to rise in the near future.

Controlled Intelligent Packaging Market: Regional Analysis Preview

North America held a share of 37% in 2020. This is due to the rising demand for packaged and frozen food. Also, the changing government regulations regarding food and packaging, focus on less food wastage and growing demand for quality packaging in order to extend the shelf life are the driving factors for such demand in this region. Also, there is a lot of scope for research and innovation which leads to major players investing in controlled intelligent packaging. Also, the presence of a strong pharmaceutical sector further boosts the overall demand for such packaging systems.

Asia-Pacific is expected to have a CAGR of 9.3% from 2024 to 2032. Countries such as India and China majorly drive the demand for the appealing and convenient packaging solution due to evolving consumer industry goods. Also, the large population with disposable income and the improving living standards drive the demand for such packaging solutions. The growing industries here are readily adopting innovative packaging solutions which mainly drive the market in this region.

Controlled Intelligent Packaging Market: Key Players & Competitive Landscape

Some of the key players in the Controlled Intelligent Packaging market include

- TempTime Corporation

- 3M

- PakSense

- Avery Dennison

- American Thermal Instruments

- R.R. Donelly Sons & Company

- International Paper

- Stora Enso

- Thin Film Electronics ASA

- Huhtamaki Group

- Smartrac N.V

- Archer Daniels Midland Co

- BASF SE

- Ball Corp

- Eastman Chemical Co

- Amcor

- Cargill Inc

- Tyson Foods

- Honeywell International Inc

- Kerry Group

- Nestle

- DowDuPont

- Steris

- among others.

In 2020, Intelligent Packaging Limited Purchaser, which is an entity controlled by Madison Dearborn Partners acquired IPL plastics, a Montreal-based sustainable packaging solutions provider, in a deal valued at around $734m on an enterprise basis and $415m on an equity basis.

The Global Controlled Intelligent Packaging Market is segmented as follows:

By Product Type

- Pouch

- Container

- Pallet

- Drum

By Application

- Pharmaceutical Industry

- Cosmetics Industry

- Food and Beverage Industry

By Sensor Types

- Bio Sensors

- Gas Sensors

- Fluorescence based sensors

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The Global Controlled Intelligent Packaging Market was valued at USD 12.94 Billion in 2023.

The Global Controlled Intelligent Packaging Market is expected to reach USD 24.10 Billion by 2032, growing at a CAGR of 6.4% between 2024 to 2032.

There has been increase in demand from the consumers for the fresh and good quality food with systematic packaging, which has been a driving factor for the food and technology industry to develop the innovative and improved concepts of technology packaging. Therefore, the manufacturers are constantly looking for the new products with the features such as UV protection, transparency and environmental protection.

North America held a share of 37% in 2020. This is due to the rising demand for packaged and frozen food. Also, the changing government regulations regarding food and packaging, focus on less food wastage and growing demand for quality packaging in order to extend the shelf life are the driving factors for such demand in this region.

Some of the key players in the Controlled Intelligent Packaging market include TempTime Corporation, 3M, PakSense, Avery Dennison, American Thermal Instruments, R.R. Donelly Sons & Company, Huhtamaki Group, Smartrac N.V, Archer Daniels Midland Co, BASF SE, Ball Corp, Eastman Chemical Co, Amcor, Cargill Inc, Tyson Foods, Honeywell International Inc, Kerry Group, Nestle, DowDuPont, and Steris among others.

Choose License Type

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed