Electrical Discharge Machine Market Size, Share, Price, Manufacturers 2028

Electrical Discharge Machine Market By Type (Sinker EDM, Wire EDM), By Application (Die Making, Mold Making, Hole Drilling, Others), By End-User Industry (Manufacturing, Energy & Power, Electrical & Electronics, Healthcare, Automotive), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2022 - 2028

| Market Size in 2021 | Market Forecast in 2028 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 5.91 Billion | USD 8.21 Billion | 17.2% | 2021 |

Electrical Discharge Machine Industry Prospective:

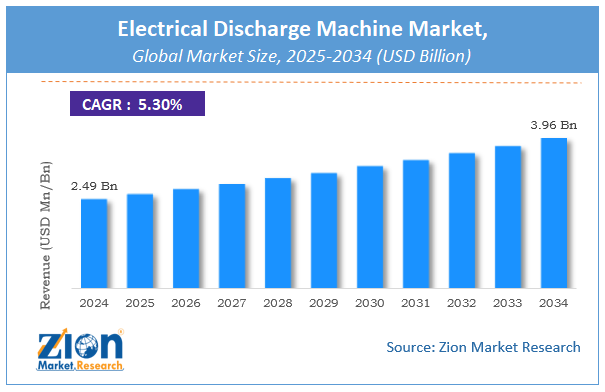

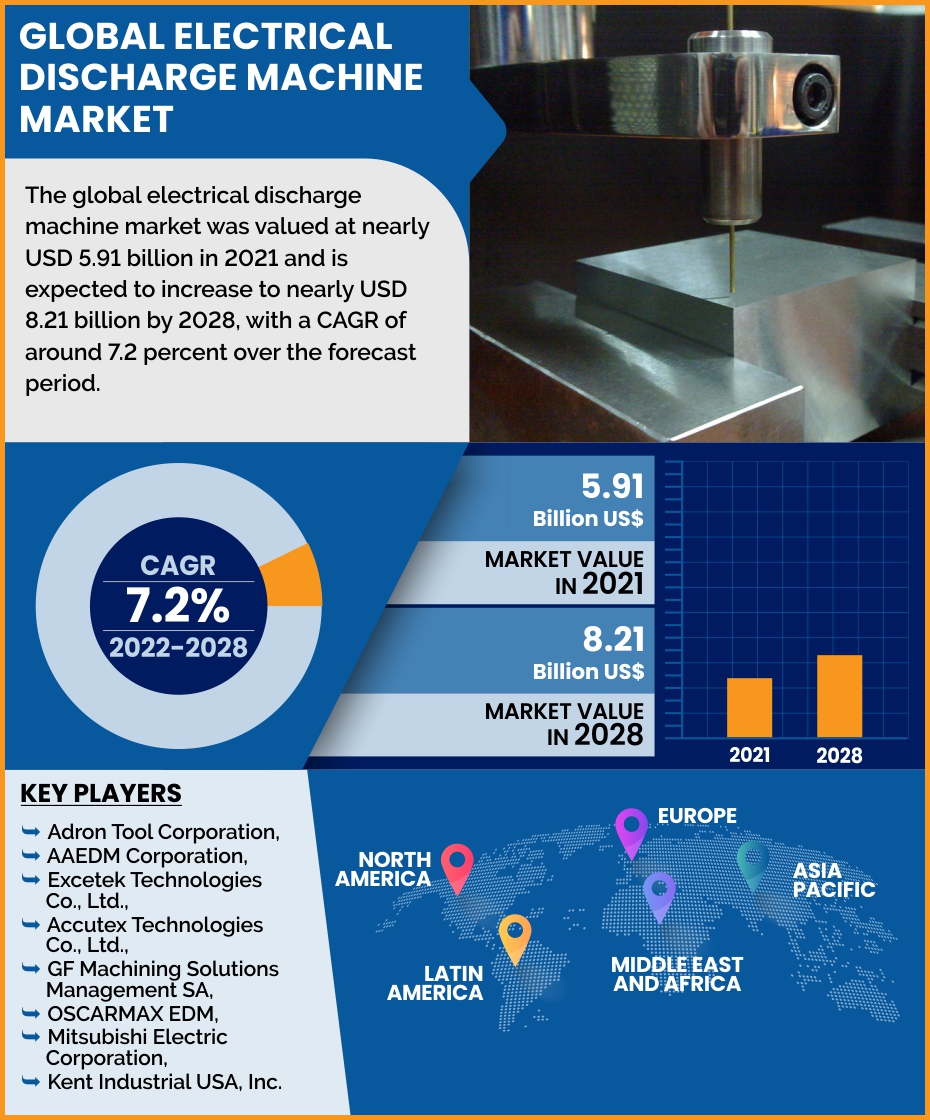

The global electrical discharge machine market was valued at nearly USD 5.91 billion in 2021 and is expected to increase to nearly USD 8.21 billion by 2028, with a CAGR of around 7.2 percent over the forecast period. The study examines the market's drivers, constraints, and challenges, as well as the impact they have on the demand throughout the forecast period. In addition, the study looks into the new potential in the market for electrical discharge machines.

Electrical Discharge Machine Market: Overview

EDM is a thermal method that uses cyclic discharge sparks in the space between an electrode and a conductive surface to remove undesired material. This approach is commonly used to process refractory metals and composite materials that are difficult to machine using traditional machining methods. Only electrically conductive materials can be processed by EDM. EDM, for example, can remove metallic materials such as Ti alloys, hardened steel, and superalloys quickly and without the need for pretreatment like thermal softening. EDM is now used in the eroding of PCBN, ceramic materials, and PCD, which considerably boosts the material removal rates of these difficult-to-machine materials.

Electrical Discharge Machine Market: Growth Drivers

Increasing need for precision in diverse component manufacturing may boost the market growth over the forecast period.

Due to changing component quality requirements and changes in industry standards, the manufacturing sector is evolving at a rapid rate. This is pushing industry participants to adapt and employ electric discharge machines for production applications such as wire cutting, manufacturing of highly precise gears & components, and precision machining of particular parts. Over the projected period, this aspect will drive market expansion. Furthermore, the skill gap is developing among workers who want to expand and improve their technical knowledge by using high-durability, high-quality materials to produce a product that meets industry requirements.

As a result, this aspect is also helping to fuel demand for this equipment, resulting in a boom in market growth. Moreover, market participants are active and engaging in the market by developing new and improved goods to meet the growing demand from various end-user industries, hence strengthening their market position and contributing to market growth. For instance, GF Machining Solutions, which manufactures and sells engineering solutions to a variety of end-user sectors, unveiled the debut of their new product, the "Agie Charmilles Cut P 500 Pro Wire-Cutting EDM," in 2019.

Electrical Discharge Machine Market: Restraints

Disadvantages with the EDM may hamper the market growth.

Because the wire-cut EDM technique eliminates material with electrical charges, it can only be used on electrically conductive workpieces. Due to this EDM cannot be utilized to machine composite or dielectric materials. When using wire EDM cutting with certain metals, a film of oxide can form on the cut surface, which needs to be wiped to retain optimal quality.

Components and parts that cannot be held securely without sacrificing their form are also a challenge for electric discharge machining. Delicate tube sections, for example, might bend while being secured for EDM cutting, causing extra quality difficulties and disrupting production. These factors are likely to hamper the global electrical discharge machine market growth.

Electrical Discharge Machine Market: Opportunities

Increasing demand from medical device manufacturers offers a better growth opportunity for the expansion of the market.

The fact that the cutting wire never contacts the workpiece means that there are no stresses introduced into the component is a major benefit of the EDM process. As a consequence, medical device makers may utilize EDM to create slots, grooves, and eyelets in machined parts while putting the least amount of stress on them. EDM's high-quality finish is another advantage. Wire cutting produces smooth, burr-free surfaces while maintaining tight tolerances.

Wire EDM may also be used to manufacture very tiny eyelets and through-slots in medical devices, which are impossible to machine with conventional centers. These factors are strongly supporting the use of EDM in the medical device manufacturing industry.

Electrical Discharge Machine Market: Challenges.

Electrical discharge machine is a more expensive process compared to turning or milling posing a challenge to market growth.

The overall EDM process adds extra cost to the product due to the slow rate of material removal and the additional cost and time used for producing electrodes for Sink or Ram EDM.

Also, reproducing sharp corners on the workpiece is difficult due to electrode wear. These factors add extra cost to the process which poses a major challenge to the use of EDM in small-scale industries.

Electrical Discharge Machine Market Report Scope:

| Report Attributes | Report Details |

|---|---|

| Report Name | Electrical Discharge Machine Market Research Report |

| Market Size in 2021 | USD 5.91 Billion |

| Market Forecast in 2028 | USD 8.21 Billion |

| Compound Annual Growth Rate | CAGR of 7.2 |

| Number of Pages | 144 |

| Forecast Units | Value (USD Billion), and Volume (Units) |

| Key Companies Covered | Adron Tool Corporation, AAEDM Corporation, Excetek Technologies Co Ltd, Accutex Technologies Co Ltd, GF Machining Solutions Management SA, OSCARMAX EDM, Mitsubishi Electric Corporation, Kent Industrial USA Inc |

| Segments Covered | By Type, By Application, By End-User and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA) |

| Countries Covered | North America: U.S and Canada Europe: Germany, Italy, Russia, U.K, Spain, France, Rest of Europe APAC: China, Australia, Japan, India, South Korea, South East Asia, Rest of Asia Pacific Latin America: Brazil, Argentina, Chile The Middle East And Africa: South Africa, GCC, Rest of MEA |

| Base Year | 2022 |

| Historical Year | 2018 - 2022 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Electrical Discharge Machine Market: Segmentation

The global electrical discharge machine market is segregated based on type, application, end-user, and region.

Based on type, the market is categorized into sinker EDM and wire EDM.

By application the market is bifurcated into mold making, die making, hole drilling, and others.

By end-user, segment of the market is divided into energy & power, manufacturing, automotive, electrical & electronics, and healthcare.

Recent Developments

- In October 2021, GF Machining Solutions promoted EDM technologies to assist manufacturers in boosting productivity and precision. These EDM machines for die-sinking and wire-cutting, as well as strong solutions for the mold and die sector, provide operational accuracy, excellent component quality, and automated choices.

- In Oct 2021, Beaumont Machine offered Small Hole EDM to SpaceX. SpaceX, a new customer for Beaumont Machine, has a new Beaumont small hole machine with an eight-foot diameter and eight-foot height reach.

Electrical Discharge Machine Market: Regional Landscape

Europe to lead the global market during the forecast period.

The global electrical discharge machine market is dominated by North America and Europe. The domination of the European market is mainly linked to the significant expansion of end-use sectors such as automotive and aerospace, as well as the resulting boost to the region's tool-making industry. The tools and molding industry is undergoing a positive response in terms of revenue and exports, as per the Machining Association (ISTMA) and International Special Toolin, as companies in European countries such as Portugal invest heavily in new technologies to ensure flexible solutions to their clients.

Asia Pacific on the other side is expected to offer more lucrative growth opportunities for market expansion. This is due to the rising industrial base backed by the increased use of automation across various sectors in countries such as India, China, Japan, and Australia.

Electrical Discharge Machine Market: Competitive Landscape

Major players operating in the global electrical discharge machine market include;

- Adron Tool Corporation

- AAEDM Corporation

- Excetek Technologies Co., Ltd.

- Accutex Technologies Co., Ltd.

- GF Machining Solutions Management SA

- OSCARMAX EDM

- Mitsubishi Electric Corporation

- Kent Industrial USA, Inc.

The global electrical discharge machine market is segmented as follows:

By Type

- Sinker EDM

- Wire EDM

By Application

- Die Making

- Mold Making

- Hole Drilling

- Others

By End-User

- Manufacturing

- Energy and Power

- Electrical and Electronics

- Healthcare

- Automotive

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Due to changing component quality requirements and changes in industry standards, the manufacturing sector is evolving at a rapid rate. This is pushing industry participants to adapt and employ electric discharge machines for production applications such as wire cutting, manufacturing of highly precise gears and components, and precision machining of particular parts. Over the projected period, this aspect will drive market expansion. Furthermore, the skill gap is developing among workers who want to expand and improve their technical knowledge by using high-durability, high-quality materials to produce a product that meets industry requirements. As a result, this aspect is also helping to fuel demand for this equipment, resulting in a boom in market growth.

According to the Zion Market Research report, the global electrical discharge machine market was worth about 5.91 (USD billion) in 2021 and is predicted to grow to around 8.21 (USD billion) by 2028, with a compound annual growth rate (CAGR) of around 7.2 percent.

The market for electrical discharge machines is dominated by North America and Europe. The domination of the European market is mainly linked to the significant expansion of end-use sectors such as automotive and aerospace, as well as the resulting boost to the region's tool-making industry. The tools and molding industry is undergoing a positive response in terms of revenue and exports, as per the Machining Association (ISTMA) and International Special Toolin, as companies in European countries such as Portugal invest heavily in new technologies to ensure flexible solutions to their clients.

Major players operating in the global electrical discharge machine market include Adron Tool Corporation, AAEDM Corporation, Excetek Technologies Co., Ltd., Accutex Technologies Co., Ltd., GF Machining Solutions Management SA, OSCARMAX EDM, Mitsubishi Electric Corporation, and Kent Industrial USA, Inc.

According to the Zion Market Research report, The global electrical discharge machine market was valued at nearly USD 5.91 billion in 2021 and is expected to increase to nearly USD 8.21 billion by 2028.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed