Extruded Polystyrene Insulation Materials Market Size, Share, Growth, Forecast 2030

Extruded Polystyrene Insulation Materials Market By Application (Residential Construction and Non-Residential Construction), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

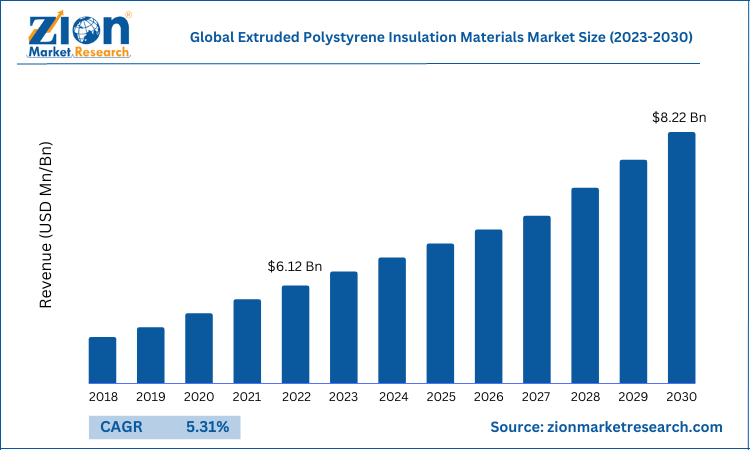

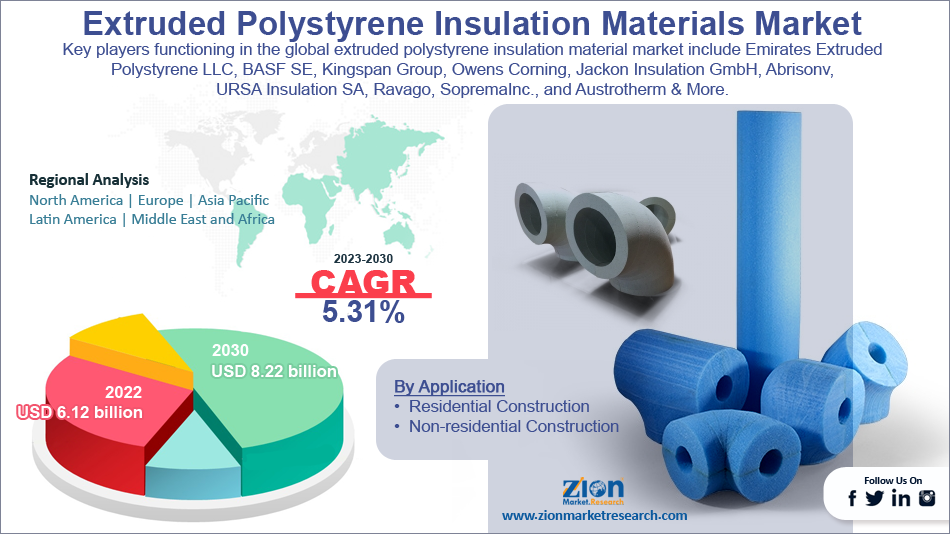

| USD 6.12 Billion | USD 8.22 Billion | 5.31% | 2022 |

Extruded Polystyrene Insulation Materials Industry Prospective:

The global extruded polystyrene insulation materials market revenue was worth around USD 6.12 Billion in 2022 and is estimated to grow to about USD 8.22 Billion by 2030, with a compound annual growth rate (CAGR) of approximately 5.31 percent over the forecast period.

The report analyzes the extruded polystyrene insulation materials market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the extruded polystyrene insulation materials market.

Extruded Polystyrene Insulation Materials Market: Overview

Extruded polystyrenes are thermoplastic polymers that are produced via extrusion. Owing to their closed cell structure, these polymers are very moisture resistant and have excellent insulating qualities. They also have excellent compressive strength, are simple to install & handle, and provide long-term thermal efficiency. They can be used in rail beds, cold storage installations, transmission line power foundations, walkaways, beneath concrete floors, underground utility lines, parking decks, fountain foundations, as well as other load-bearing purposes on both the inside and outside.

Key Insights

- As per the analysis shared by our research analyst, the global extruded polystyrene insulation materials market is expected to grow annually at a promising CAGR of around 5.31% during the forecast period 2023-2030.

- In terms of revenue, the global extruded polystyrene insulation materials market size was valued at around USD 6.12 billion in 2022 and is estimated to grow to about USD 8.22 billion by 2030.

- The rapid expansion of the real estate sector and growth in the economy in various countries has led to an increase in construction activities in the last couple of years. Thus, an increase in the construction of green buildings and the growing trend of constructing smart cities propel the growth of the market.

- Based on application, the non-residential segment led the dominating market share in 2022.

- Based on region, the Asia-Pacific region held the largest market share in 2022.

To know more about this report, Request a sample copy

COVID-19 Impact:

COVID-19 had a negative impact on market growth in 2020. The breakout of COVID-19 caused a lack of funding, labor shortages, and lockdown restrictions which is why many projects were suspended in 2020. Migrant laborers wrecked chaos and ceased working on building projects in numerous industrialized and developing nations, including the United States, China, and India, owing to an interstate travel prohibition. This disrupts the supply chain, resulting in lower building material use and lower demand & supply for extruded polystyrene.

Extruded Polystyrene Insulation Materials Market: Growth Drivers

The need for green buildings is fueled by the increased impact of constructing buildings on the environment and human health.

Green construction denotes the use of environmentally friendly and resource-efficient methods at every level of the construction process. Green construction is primarily concerned with boosting the building's energy efficiency and reducing waste linked with the use of materials, water, and energy.

Extruded insulation materials are an important aspect of green building since they help reduce the structure's energy consumption. This benefits both the environment and the immediate owner by cutting energy expenses and reducing greenhouse gas emissions. In addition to this, it is less dangerous to the ozone layer.

Extruded polystyrene (XPS) is homogeneous polystyrene that comes in a variety of hues, including green, blue, and pink. XPS starts as a molten substance that is pressed into sheets from a mould. It's most typically used as foam board insulation, and it's also regularly utilized to insulate structural insulating panels and concrete forms (ICFs). HCFCs are largely used in XPS Insulation Materials.

CFCs are 90 percent more destructive to the ozone layer than these alternatives. The aforementioned benefits of XPS drive manufacturers to use it over alternative reinforcing materials. All these factors are driving the growth of the global extruded polystyrene insulation materials market.

Extruded Polystyrene Insulation Materials Market: Restraints

Raw material costs fluctuate, and the presence of dangerous substances may impede market growth.

The market's expansion is expected to be hampered by fluctuating raw material prices and questions about the presence of harmful chemicals. Furthermore, due to its exceptional properties, the cost of installation is quite high, which is slowing the extruded polystyrene insulation materials industry's growth. The presence of a large number of replacements is seen to be a difficult element for market development. Hexabromocyclododecane (HBDC) found in polystyrene is categorized as a chemical of great concern by the European Union's (EU) Registration, Evaluation, Authorization, and Restriction of Chemicals (REACH) program, which advocates limiting its usage as much as feasible.

Extruded Polystyrene Insulation Materials Market: Opportunities

Advancement in technology may generate ample opportunities for the market growth

Thermal welding, the contactless procedure allows a range of insulation materials to be combined. Styrodur®, a stiff extruded polystyrene foam from BASF, for example, may be coupled with the melamine resin foam Basotect® or the polyurethane, inorganic insulation materials, to create whole new insulation materials solutions. Thus, technological advancements for the development of advanced material is likely to boost the extruded polystyrene insulation materials market during the forecast period.

Extruded Polystyrene Insulation Materials Market: Challenges

Disadvantages associated with the extruded polystyrene insulation material pose challenges to the market growth

Low vapor permeability, UV sensitivity, and poor sound insulation are some of the disadvantages associated with the use of extruded polystyrene insulation material. However, the biggest disadvantage of this type of material is its limited fire resistance. As soon as the stove's edge lights up, the flame consumes it entirely. Furthermore, burning releases very poisonous compounds into the environment, such as phenols, which can be just as hazardous to the lungs as the high temperature itself. Extruded polystyrene foam may catch fire at temperatures ranging from 250 to 450 degrees Celsius, depending on external variables. All such factors may serve as challenges to extruded polystyrene insulation materials industry growth.

Extruded Polystyrene Insulation Materials Market: Segmentation

The global extruded polystyrene insulation materials market is categorized based on application and region.

The application segment of the market is bifurcated into residential construction and non-residential construction. In 2022, the non-residential construction segment had the majority of the market share. Because of its excellent compressive strength and minimal water absorption, extruded polystyrene is commonly used in non-residential construction. In commercial and industrial construction, it is extensively utilized in roof and wall applications.

Recent Developments

- In October 2021, Kingspan Ireland-based company announced the acquisition of Minnesota Diversified Products, the manufacturer of the DiversiFoam range of expanded polyisocyanurate (PIR) foam billets, and extruded polystyrene (XPS) foam and polystyrene (EPS). In August 2020, Owens Corning unveiled Foamular NGX, a new range of extruded polystyrene (XPS) foam insulation products.

- In August 2020, Owens Corning, a dominant American manufacturer of fiberglass composites and related products and materials, announced the launch of its new range of extruded polystyrene (XPS) foam insulation products which is known as Foamular NGX. This innovative line of products is set to provide effective results as the blowing agent in the products is known to bring about a 90% depletion in global warming potential (GWP) without neglecting the performance of the product.

Extruded Polystyrene Insulation Materials Market Report Scope:

| Report Attributes | Report Details |

|---|---|

| Report Name | Extruded Polystyrene Insulation Materials Market Research Report |

| Market Size in 2022 | USD $6.12 Billion |

| Market Forecast in 2030 | USD $8.22 Billion |

| Compound Annual Growth Rate | CAGR of 5.31% |

| Number of Pages | 207 |

| Forecast Units | Value (USD Billion), and Volume (Units) |

| Key Companies Covered | Emirates Extruded Polystyrene LLC, BASF SE, Kingspan Group, Owens Corning, Jackon Insulation GmbH, Abrisonv, URSA Insulation SA, Ravago, SopremaInc., and Austrotherm. Other emerging players working in this market include Loyal Group, Penoplex SPB LLC, Knauf Insulation, Foamex Victoria Pty., Ltd., Xella International GmbH, Synthos S.A, Technonicol Corporation, and The Ravago Group. |

| Segments Covered | By Application, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA) |

| Countries Covered | North America: U.S and Canada Europe: Germany, Italy, Russia, U.K, Spain, France, Rest of Europe APAC: China, Australia, Japan, India, South Korea, South East Asia, Rest of Asia Pacific Latin America: Brazil, Argentina, Chile The Middle East And Africa: South Africa, GCC, Rest of MEA |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Extruded Polystyrene Insulation Materials Market: Regional Landscape

Asia Pacific to witness substantial growth during the forecast period

Asia Pacific region had the largest proportion of the global extruded polystyrene insulation material market. This is due to the support of private ownership of the real estate and an increase in house remodeling and construction, the demand for XPS insulation in Asia Pacific has been steadily increasing. Furthermore, the Chinese government has set up rules that encourage construction energy efficiency.

Government measures to boost construction spending to enhance commercial and public infrastructure, as well as energy conservation programs to minimize emissions of greenhouse gases, are expected to boost market growth. The market is also influenced by population and economic expansion, as well as increases in building floor space and service demand. Moreover, in the near future, increasing industrialization and rising living standards in this region's emerging countries are likely to provide significant development prospects for existing and new market competitors.

Extruded Polystyrene Insulation Materials Market: Competitive Landscape

Key players functioning in the global extruded polystyrene insulation material market include:

- Emirates Extruded Polystyrene LLC

- BASF SE

- Kingspan Group

- Owens Corning

- Jackon Insulation GmbH

- Abrisonv

- URSA Insulation SA

- Ravago

- SopremaInc.

- and Austrotherm.

- Penoplex SPB LLC

- Knauf Insulation

- Foamex Victoria Pty. Ltd.

- Xella International GmbH

- Synthos S.A

- Technonicol Corporation

- The Ravago Group.

Global extruded polystyrene insulation materials market is segmented as follows:

By Application

- Residential Construction

- Non-residential Construction

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Extruded polystyrenes are thermoplastic polymers that are produced via extrusion. Owing to their closed cell structure, these polymers are very moisture resistant and have excellent insulating qualities. They also have excellent compressive strength, are simple to install & handle, and provide long-term thermal efficiency.

The need for green buildings is fueled by the increased impact of constructing buildings on the environment and human health. Green construction denotes the use of environmentally friendly and resource-efficient methods at every level of the construction process. Green construction is primarily concerned with boosting the building's energy efficiency and reducing waste linked with the use of materials, water, and energy.

According to the Zion Market Research report, the global extruded polystyrene insulation materials market was worth about USD 6.12 billion in 2022 and is estimated to grow to about USD 8.22 billion by 2030.

The global extruded polystyrene insulation materials market is expected to grow at a rapid CAGR of 5.31% during the forecast period.

Asia Pacific region had the largest proportion of the global extruded polystyrene insulation material market. This is due to the support of private ownership of the real estate and an increase in house remodeling and construction, the demand for XPS insulation in Asia-Pacific has been steadily increasing.

Key players functioning in the global extruded polystyrene insulation material market include as Emirates Extruded Polystyrene LLC, BASF SE, Kingspan Group, Owens Corning, Jackon Insulation GmbH, Abrisonv, URSA Insulation SA, Ravago, SopremaInc., and Austrotherm. Other emerging players working in this market include Loyal Group, Penoplex SPB LLC, Knauf Insulation, Foamex Victoria Pty., Ltd., Xella International GmbH, Synthos S.A, Technonicol Corporation, and The Ravago Group.

Choose License Type

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed