Industrial connector Market Size, Share, Industry Analysis, Trends, Growth, 2030

Industrial connector Market By Termination Method (Soldering, Crimping, and Others), By Connector Type (Rectangular, Circular, PCB, Coaxial, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

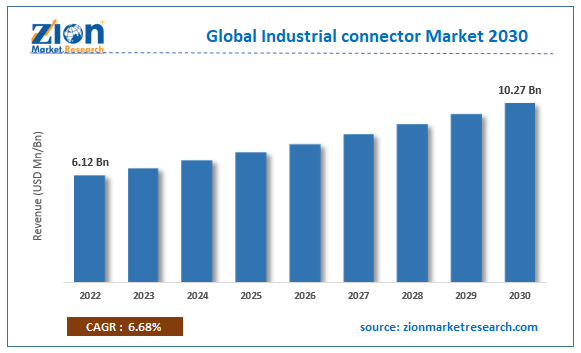

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 6.12 Billion | USD 10.27 Billion | 6.68% | 2022 |

Industrial Connector Industry Prospective:

The global industrial connector market size was worth around USD 6.12 billion in 2022 and is predicted to grow to around USD 10.27 billion by 2030 with a compound annual growth rate (CAGR) of roughly 6.68% between 2023 and 2030.

Industrial Connector Market: Overview

Industrial connectors are extremely crucial components of modern industrial devices. They are used for the secure transmission of all industrial signals. In an industrial setting, these connectors have a wide role to play as they provide crucial support to multiple applications. They are required for routing power and signals between devices across industries including aviation, medical devices, industrial machinery, test & measurement, communication, and others. Although the physical structure of industrial detonators is extremely simple, their internal mechanism includes complex and sophisticated electrical networks. While some industrial connectors are used to withstand extreme environmental conditions including heat and low temperatures, this statement does not hold for all connectors. Industrial connectors are currently available in 4 main types that are cable-to-cable connectors, board-to-board connectors, panel feedback, and wire-to-board connectors. Each connector has specific advantages and is best suited for certain applications. The industry for industrial connectors is expected to grow at a tremendous pace during the forecast period.

Key Insights:

- As per the analysis shared by our research analyst, the global industrial connector market is estimated to grow annually at a CAGR of around 6.68% over the forecast period (2023-2030)

- In terms of revenue, the global industrial connector market size was valued at around USD 6.12 billion in 2022 and is projected to reach USD 10.27 billion, by 2030.

- The industrial connector market is projected to grow at a significant rate due to the increasing rate of industrial automation

- Based on termination method segmentation, soldering was predicted to show maximum market share in the year 2022

- Based on connector type segmentation, rectangular was the leading type in 2022

- On the basis of region, Asia-Pacific was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Industrial Connector Market: Growth Drivers

Increasing rate of industrial automation to drive growth for highly advanced industrial connectors

The global industrial connector market is expected to be driven by the increasing rate of automation in industrial units. It refers to the extensive use of advanced systems such as robotics and computer software to control machines and equipment used in an industrial facility. Earlier automation played a key role in reducing dependence on large human forces and quality control. However, in recent times, the advancements in automation solutions have allowed these technologies to have higher applications. For instance, the automobile industry has been completely revolutionized after adopting automated machinery that installs car pistons. Research suggests that automation has helped in reducing the error rate to 0.00001% as compared to the previous rate of 1-1.5% when car pistons were installed manually.

On the other hand, the manufacturing industry is one of the largest beneficiaries of automation as routine labor-intensive tasks can be conducted using robots while human resources get to play other critical roles. These automatic machines can perform the same tasks multiple times without compromising on quality. In addition to this, the rising proliferation of the Internet of Things (IoT) in industries will help push the demand for industrial connectors. IoT refers to interconnected devices that exchange data using the internet and connecting devices. This trend is mainly related to the growing popularity of Industry 4.0 also known as the fourth industrial revolution. Industry 4.0 and IoT work in tandem to improve industrial outputs, especially in current times when consumerism is reaching new heights with every passing year.

Increased applications in the medical devices segment to create high-revenue

The global industrial connector market growth is expected to be further propelled to new horizons due to the increasing use of efficient industrial connectors in the medical devices sector. The growing rate of patients and intense requests for quality medical care have resulted in higher development of advanced interconnected medical equipment. These connectors must continue to perform functions in harsh chemical and medical conditions while delivering on aspects such as high Ingress Protection (IP) rating, mating cycle, excellent Electromagnetic Interference and Radio Frequency Interference performance, and quick connect/disconnect capability

Industrial Connector Market: Restraints

Installation complexities associated with industrial connectors to restrict market growth

The revenue in the industrial connector industry is expected to be restrained owing to the complexities associated with the installation of industrial connectors. These tools employ extremely sophisticated internal structures and they should be handled in the presence of skilled professionals. The installation of industrial connectors demands expertise especially when dealing with highly advanced and specific connectors such as rectangular and circular variants. Furthermore, the growing trend of miniaturizing industrial connectors without diminishing product performance creates additional barriers.

Industrial Connector Market: Opportunities

Rising investments in 5G infrastructure poses as excellent expansion opportunities

The global industrial connector market players are projected to come across excellent expansion opportunities during the forecast period as a result of growing investments in 5G infrastructure across the globe. The telecommunication industry is rapidly advancing toward faster connectors across sectors. The growing demand for reliable internet connectivity with minimum latency in military, healthcare, and commercial segments are some of the key drivers for 5G infrastructure. As per official reports, NTT Docomo, a Japanese mobile phone operator, has invested 1 trillion yen in Japan’s 5G network between 2019 and 2023. The company constructed around 10,000 5G bases in June 2021 with additional 20,000 bases in 2022.

Growing launch of new connectors with novel features to deliver growth possibilities

The increasing launch of novel connectors along with rapid expansion of existing product lines are anticipated to help the industrial connector industry grow further during the forecast period. In December 2021, Phoenix Contact, a leading manufacturer of industrial automation solutions launched a new range of printed circuit board (PCB) connectors with applications in power connection, signal, and data transfer. The product ranges vary between 2.5 mm to 20 mm pitch and have ratings up to 232A.

Industrial Connector Market: Challenges

Providing customized solutions and issues with interoperability may challenge the market growth

The global industrial connector market is technically advanced and hence is associated with several technical challenges. For instance, ensuring seamless integration of various devices using industrial connectors is a highly time-consuming and tedious task. On the other hand, meeting specific connector requirements for certain applications adds to the already complex nature of the tool. Other factors such as changing global connections and rising issues faced in terms of supply of raw materials and final goods further create barriers against growth.

Industrial Connector Market: Segmentation

The global industrial connector market is segmented based on termination method, connector, type, and region.

Based on the termination method, the global market is segmented into soldering, crimping, and others. In 2022, the highest demand was observed in the soldering method which involves the use of a low-temperature metal alloy for creating a connection between the device and the final terminal. This method has permanent and strong results. Crimping, on the other hand, works with the use of a crimping tool that helps to compress and insert connector terminals into the wire. The choice of termination method depends on the ultimate goal of the connection. Standard industrial connectors can handle a temperature range of -40°F to 185°F.

Based on connector type, the industrial connector industry segments are rectangular, circular, PCB, coaxial, and others. In 2022, the rectangular variant generated the highest revenue owing to its space efficiency. As per studies, one rectangular connector can replace the performance of 2 circular connectors by affecting the required space and simplifying the layout of wires outside and inside the device. They are also less resource-intensive. During the forecast period, the rectangular segment is likely to grow at a CAGR of more than 5%.

Industrial connector Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Industrial connector Market |

| Market Size in 2022 | USD 6.12 Billion |

| Market Forecast in 2030 | USD 10.27 Billion |

| Growth Rate | CAGR of 6.68% |

| Number of Pages | 205 |

| Key Companies Covered | Amphenol Corporation, TE Connectivity, Phoenix Contact, Molex, ODU Group, Harting Technology Group, Hirschmann Automation and Control, LEMO SA, Weidmüller Interface GmbH & Co. KG, ITT Inc., Hirose Electric Co. Ltd., Fischer Connectors, Smiths Interconnect, SOURIAU - SUNBANK Connection Technologies, Radiall, and others. |

| Segments Covered | By Termination Method, By Connector Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Industrial Connector Market: Regional Analysis

Asia-Pacific to continue leading the way during the forecast period

The global industrial connector market is currently dominated by Asia-Pacific due to the rising production of industrial connectors in countries such as Japan, India, and China. These nations have an extensive domestic presence of key industrial connector manufacturers catering to the needs of the local market as well as international players across sectors. The growing industrialization rate in Asian countries along with the availability of large-scale production lines and skilled workforce has helped Asia-Pacific continue to dominate the global revenue streams. In February 2021, Kyocera Corporation launched a new and advanced 0.5mm-pitch floating board-to-board connector series of industrial connectors. These products exhibit a speed of 16Gbps data transmission and are sold under the 5652 Series designation. The equipment innovation trend has been one of the crucial selling points for Asia-based manufacturers of industrial connectors. Europe is expected to deliver significant results. The rising automation in industrial facilities and growing demand for aircraft applications will drive growth in Europe.

Industrial Connector Market: Competitive Analysis

The global industrial connector market is led by players like:

- Amphenol Corporation

- TE Connectivity

- Phoenix Contact

- Molex

- ODU Group

- Harting Technology Group

- Hirschmann Automation and Control

- LEMO SA

- Weidmüller Interface GmbH & Co. KG

- ITT Inc.

- Hirose Electric Co. Ltd.

- Fischer Connectors

- Smiths Interconnect

- SOURIAU - SUNBANK Connection Technologies

- Radiall

The global industrial connector market is segmented as follows:

By Termination Method

- Soldering

- Crimping

- Others

By Connector Type

- Rectangular

- Circular

- PCB

- Coaxial

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Industrial connectors are extremely crucial components of modern industrial devices. They are used for the secure transmission of all industrial signals.

The global industrial connector market is expected to be driven by the increasing rate of automation in industrial units.

According to study, the global industrial connector market size was worth around USD 6.12 billion in 2022 and is predicted to grow to around USD 10.27 billion by 2030.

The CAGR value of the industrial connector market is expected to be around 6.68% during 2023-2030.

The global industrial connector market is currently dominated by Asia-Pacific due to the rising production of industrial connectors in countries such as Japan, India, and China.

The global industrial connector market is led by players like Amphenol Corporation, TE Connectivity, Phoenix Contact, Molex, ODU Group, Harting Technology Group, Hirschmann Automation and Control, LEMO SA, Weidmüller Interface GmbH & Co. KG, ITT Inc., Hirose Electric Co., Ltd., Fischer Connectors, Smiths Interconnect, SOURIAU - SUNBANK Connection Technologies, and Radiall.

The report explores crucial aspects of the industrial connector market including a detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

Choose License Type

List of Contents

Industrial ConnectorIndustry Prospective:Industrial Connector OverviewKey Insights:Industrial Connector Growth DriversIndustrial Connector RestraintsIndustrial Connector OpportunitiesIndustrial Connector ChallengesIndustrial Connector SegmentationReport ScopeIndustrial Connector Regional AnalysisIndustrial Connector Competitive AnalysisThe global industrial connector market is segmented as follows:By RegionHappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed