Industrial Gears Market Size, Share, Growth, Trends, and Forecast 2030

Industrial Gears Market By Application (Power Plants, Oilfield Equipment, Construction Machinery, Mining Equipment, Sugar Industry, Power Plants, and Others), By Product Type (Rack & Pinion Gear, Spur Gear, Bevel Gear, Planetary Gear, Worm Gear, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

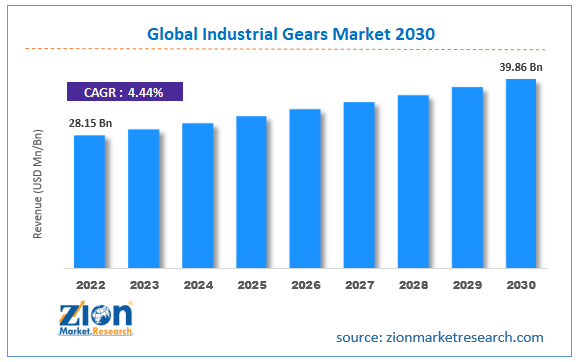

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 28.15 Billion | USD 39.86 Billion | 4.44% | 2022 |

Industrial Gears Industry Prospective:

The global industrial gears market size was worth around USD 28.15 billion in 2022 and is predicted to grow to around USD 39.86 billion by 2030 with a compound annual growth rate (CAGR) of roughly 4.44% between 2023 and 2030.

Industrial Gears Market: Overview

Industrial gears are a crucial part of the heavy machinery industry. An industrial gearbox is defined as an enclosed system capable of transmitting mechanical energy to the output device. It helps in transferring power between connected systems and creates a large scope for changes in loads or speeds that can be achieved for a fixed range of input loads or speeds. They are available in several unique materials and designs depending on the end application. Some important and more widely used industrial gears include bevel gears, spur gears, helical gears, planetary or elliptical gears, and worm gears. Each variant has a specific function to perform and is used in several industries such as aerospace, manufacturing, oil & gas, automotive, chemical, pulp & paper industry, water and wastewater management, pharmaceutical, and many more. Asia-Pacific is one of the leading regions that has helped in shaping the industrial gears industry as it continues to promote the existence and expansion of an undefeated heavy machinery regional market.

Key Insights:

- As per the analysis shared by our research analyst, the global industrial gears market is estimated to grow annually at a CAGR of around 4.44% over the forecast period (2023-2030)

- In terms of revenue, the global industrial gears market size was valued at around USD 28.15 billion in 2022 and is projected to reach USD 39.86 billion, by 2030.

- The industrial gears market is projected to grow at a significant rate due to the increasing launch of new and efficient gears

- Based on application segmentation, construction machinery was predicted to show maximum market share in the year 2022

- Based on product type segmentation, spur gear was the leading type in 2022

- On the basis of region, Asia-Pacific was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Industrial Gears Market: Growth Drivers

Increasing launch of new and efficient gears to drive market growth

The global industrial gears market is projected to grow owing to the rising innovation in the field of heavy machinery, particularly industrial gears. One of the key factors influencing industry innovation is the changing equipment needs of end-user sectors. The final consumer verticals are evolving, requiring industrial gear manufacturers to stay aligned with the market demand and expectations. In March 2023, Elecon Engineering Company Limited (Elecon), a global firm and one of Asia’s biggest manufacturers of industrial gears, announced the launch of EON series gearboxes that boast advanced features. The company already deals with providing solutions such as defense gearboxes and customized gearboxes, but the latest addition of ‘NEW EON’ is expected to strengthen the company’s footprint in the global scenario. NEW EON is compact in size and easy to install. It also has an excellent gear and torque ratio and, as per company claims, will have less downtime thus improving overall productivity for Elecon clients. In 2019, another important player, Premium Transmission launched a massive product range consisting of 7 clutter-breaking products that included a Small Planetary Gearbox, PCX-SERIES Cooling Tower Gearbox, Smart Modular Series- Helical Gearbox, Gearless Lift Machine, Inline Geared Motor, Modular Fluid Coupling, and Geared Lift Machine. The company manufactures these products across 3 state-of-the-art facilities owned by Premium Transmission.

Rising applications in the construction & building sector to push the demand rate

The global industrial gears market conditions are projected to economically advance due to higher demand for modern industrial gears in the expanding construction & buildings sector. Industrial gears from standard components of large machinery used in the construction sector including tools such as concrete mixers, hoists, cranes, excavators, scaffolding systems, conveyors, and tower cranes. The increasing manufacturing of heavy machines used in building & construction along with a rising number of infrastructure development projects are expected to create a higher growth scope for industrial gears. As per recent developments, Mammoet, a leading solution provider for heavy lifting, invested in the construction of the world’s largest ring crane with a capacity of 6,000t. The delivery of the mammoth crane is expected in 2024.

Industrial Gears Market: Restraints

High initial investment and requirement of skilled labor force to restrict market growth

The industrial gears industry growth trend is projected to be limited due to the high cost of initial investment required to build manufacturing facilities along with raw material procurement. Industrial gear manufacturing requires a skilled labor force and the process is a combination of manual and automated work. The key factors that lead to the high initial investment are the type of raw materials used for industrial gears and the use of ancillary heavy machinery for lifting and transporting large gears. The essential primary materials are steel, bronze, cast iron, powdered metal, ceramics, and in some cases composite material. These factors make it difficult for small companies to explore the market offerings.

Industrial Gears Market: Opportunities

Investing in military applications poses excellent expansion opportunities

The global industrial gears market players can expect crucial growth opportunities arising from the increasing application of industrial gears in military equipment including aircraft, missile systems, ground vehicles, radar systems, naval vessels, and guidance & control systems. The changing world order and increasing interregional conflicts have resulted in country governments taking national safety more seriously and investing large resources in upgrading their defense systems. This trend is visible from the several new partnerships signed by countries across the globe for the procurement of new military-grade equipment. For instance, as per the latest news, countries including India and China are eyeing the African market for the sale of military weapons. On the other hand, these countries are also collaborating with other prominent military equipment manufacturers for domestic use. A July 2023 report claimed that Israel will be investing in buying a new fleet of F-35 stealth fighter jets from the US. The deal is worth USD 3 billion. Industrial gearboxes are important components of this equipment and ensure proper functionality.

Rising demand for composite materials holds large-scale growth possibilities

The market for composite materials is on the rise. In 2022, the global composite material market was valued at more than USD 114 billion. The increasing use in industries such as space exploration, aerospace, automotive, and marine will result in higher consumption of strong and resistant composite material that in turn will impact the revenue streams for industrial gears.

Industrial Gears Market: Challenges

Supply chain disruptions and changing prices of raw materials to challenge market growth

The key challenge faced by the industrial gears industry players is navigating through supply chain disruptions related to raw material procurement and delivery of final goods. Furthermore, the fluctuating prices of essential raw materials such as steel, bronze, and other items further increased market volatility. Industrial gears are subject to frequent wear and tear and require repair or reinstallation on a regular basis which could impact the client's productivity rate.

Industrial Gears Market: Segmentation

The global industrial gears market is segmented based on application, product type, and region.

Based on application, the global market segments are power plants, oilfield equipment, construction machinery, mining equipment, sugar industry, power plants, and others. In 2022, the construction industry was the leading revenue generator. During the forecast period, the growing use of construction machinery for infrastructure development projects is expected to act as an important growth propeller. Additionally, rising housing demands and increasing focus on commercial estate construction may assist the segment in gaining more momentum. By 2030, the global construction market may reach over USD 15 trillion in value.

Based on product type, the industrial gears industry divisions are rack & pinion gear, spur gear, bevel gear, planetary gear, worm gear, and others. The most widely popular gear systems are spur gears. They are cylindrically shaped and are used in several industrial applications. Spur gears consist of toothed components while being known for high reliability, durability, effectiveness, and providing constant positive speed drive necessary for industrial applications. Spur gears used in the automotive sector are expected to generate around USD 44 billion by 2030 in terms of revenue.

Industrial Gears Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Industrial Gears Market |

| Market Size in 2022 | USD 28.15 Billion |

| Market Forecast in 2030 | USD 39.86 Billion |

| Growth Rate | CAGR of 4.44% |

| Number of Pages | 207 |

| Key Companies Covered | SEW-EURODRIVE, David Brown Santasalo, Siemens, Renold, Rexnord, ABB, Brevini Power Transmission, Sumitomo Heavy Industries, Horsburgh & Scott, Bonfiglioli, and others. |

| Segments Covered | By Application, By Product Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Industrial Gears Market: Regional Analysis

Global revenue will be directly proportional to growth in Asia-Pacific

The global industrial gears market will be led by Asia-Pacific during the forecast period. The primary reasons include the presence of a robust industrial gears manufacturing ecosystem and the growing number of players operating in the regional market supplying industrial gears to domestic and international clients. China is focusing on specialized product development and expanding its global trade by tying up with emerging nations. It is also leveraging its skilled labor force to deliver customized industrial gear leading to growing popularity in the international market. India on the other hand is equipped with multiple producers and suppliers of industrial gears. The growing research, innovation, and product portfolio expansion is likely to boost India’s growth rate. Furthermore, Asian nations have a high demand for heavy machines across sectors as these economies are growing rapidly. The highest regional demand for industrial gears is observed in sectors such as construction & building, power plant construction, and pulp & paper industry.

Industrial Gears Market: Competitive Analysis

The global industrial gears market is led by players like:

- SEW-EURODRIVE

- David Brown Santasalo

- Siemens

- Renold

- Rexnord

- ABB

- Brevini Power Transmission

- Sumitomo Heavy Industries

- Horsburgh & Scott

- Bonfiglioli

The global industrial gears market is segmented as follows:

By Application

- Power Plants

- Oilfield Equipment

- Construction Machinery

- Mining Equipment

- Sugar Industry

- Power Plants

- Others

By Product Type

- Rack & Pinion Gear

- Spur Gear

- Bevel Gear

- Planetary Gear

- Worm Gear

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Industrial gears are a crucial part of the heavy machinery industry. An industrial gearbox is defined as an enclosed system capable of transmitting mechanical energy to the output device.

The global industrial gears market is projected to grow owing to the rising innovation in the field of heavy machinery, particularly industrial gears.

According to study, the global industrial gears market size was worth around USD 28.15 billion in 2022 and is predicted to grow to around USD 39.86 billion by 2030.

The CAGR value of the industrial gears market is expected to be around 4.44% during 2023-2030.

The global industrial gears market will be led by Asia-Pacific during the forecast period.

The global industrial gears market is led by players like SEW-EURODRIVE, David Brown Santasalo, Siemens, Renold, Rexnord, ABB, Brevini Power Transmission, Sumitomo Heavy Industries, Horsburgh & Scott, and Bonfiglioli among others.

The report explores crucial aspects of the industrial gears market including a detailed discussion of existing growth factors and restraints while also browsing future growth opportunities and challenges that impact the market.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed