Injection Molding Market Size, Share, Analysis, Trends, Growth, 2032

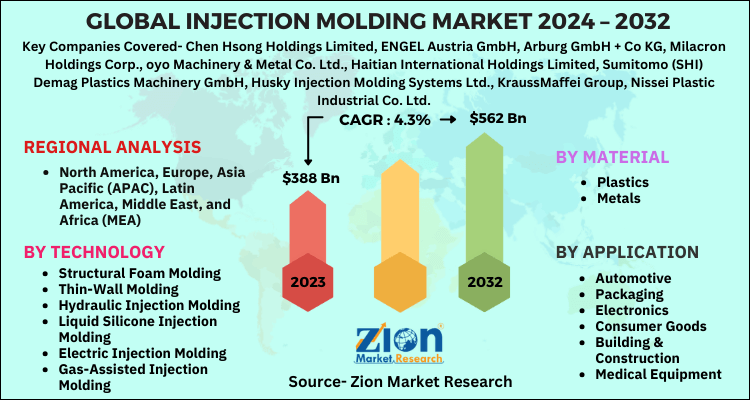

Injection Molding Market By Material (Plastics and Metals), By Application (Automotive, Packaging, Electronics, Consumer Goods, Building & Construction, and Medical Equipment), By Technology (Structural Foam Molding, Thin-Wall Molding, Hydraulic Injection Molding, Liquid Silicone Injection Molding, Electric Injection Molding, and Gas-Assisted Injection Molding), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

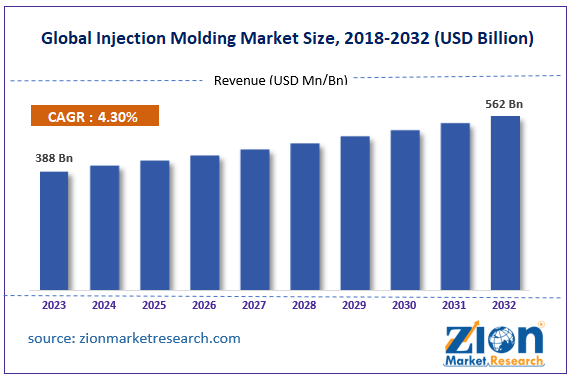

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 388 Billion | USD 562 Billion | 4.3% | 2023 |

Injection Molding Industry Prospective:

The global injection molding market size was evaluated at $388 billion in 2023 and is slated to hit $562 billion by the end of 2032 with a CAGR of nearly 4.3% between 2024 and 2032.

Injection Molding Market: Overview

Injection molding is a production process used for manufacturing components by injecting molten material into a mold. This process can be performed using a host of materials such as metals, elastomers, thermosetting polymers, elastomers, glasses, and thermoplastics.

Reportedly, these materials are fed into a heated barrel, mixed, and inserted into a mold, where it cools and solidifies into a cavity. Moreover, the injection molding method is utilized in a slew of end-use sectors to output a vast spectrum of goods.

Key Insights

- As per the analysis shared by our research analyst, the global injection molding market is projected to expand annually at the annual growth rate of around 4.3% over the forecast timespan (2024-2032)

- In terms of revenue, the global injection molding market size was evaluated at nearly $388 billion in 2023 and is expected to reach $562 billion by 2032.

- The global injection molding market is anticipated to grow rapidly over the forecast timeline owing to the humungous use of lightweight & durable components in the automotive & electronics sectors.

- In terms of material, the plastics segment is slated to register the highest CAGR over the forecast period.

- Based on application, the automotive segment is predicted to contribute majorly towards segmental space in the upcoming years.

- Based on technology, the electric injection molding segment is likely to lead the global market growth in the ensuing years.

- Region-wise, the North American injection molding industry is projected to register the fastest CAGR during the assessment timespan.

Injection Molding Market: Growth Factors

Large-scale application of the product in electronics & automotive sectors will prop up the global market trends

Humungous use of lightweight & durable components in the automotive & electronics sector will steer the global injection molding market progression.

Technological innovations such as multi-component injection molding and high-speed injection molding will spur the market space globally in the near future. Massive use of personalized products and the flourishing healthcare sector will proliferate the global market size.

Humungous end-user preference for durable goods is likely to impel the global market surge. The ability of injection molding in providing cost-efficient solutions for mass production at reasonable prices will elevate the global market trends in the ensuing years.

Focus on sustainable manufacturing, along with the demand for medical equipment, is expected to increase the growth of the global market.

Injection Molding Market: Restraints

Non-degradable nature of plastics can impede the global industry surge over the forecast period

The timeline needed for designing, testing, and producing molds can result in elongated lead times before production, resulting in fluctuating demand for injection moldings, thereby hindering the global injection molding industry surge.

Additionally, the non-recyclable nature of plastics and the power-intensive characteristics of the process can retard the global industry expansion.

Injection Molding Market: Opportunities

Massive use of injection molding in additive manufacturing to create new growth facets for the global market

Digital manufacturing and the combination of injection molding with 3D printing for creating complex components with sophisticated designs will generate new growth avenues for the global injection molding market.

Furthermore, escalating demand for lightweight parts for the aerospace and automotive sectors will impel the market evolution in the years to come.

Injection Molding Market: Challenges

Supply chain convolutions leading to irregular raw material supply to obstruct the global industry surge by 2032

Need for huge capital investments along with quality control issues can challenge the growth of the global injection molding industry.

Furthermore, oscillating supply chain activities are expected to obstruct the global industry progression in the years ahead. Labor shortage will shrink the global industry surge in the ensuing years.

Injection Molding Market: Segmentation

The global injection molding market is divided into material, application, technology, and region.

In terms of material, the injection molding market across the globe is segmented into plastics and metals segments.

Apparently, the plastics segment, which gathered nearly 50% of the global market earnings in 2023, is expected to record the fastest CAGR in the coming eight years due to beneficial features of the raw materials such as polypropylene, high-density polyethylene, polystyrene, polycarbonate, and acrylonitrile butadiene styrene used in plastic manufacturing.

Apart from this, plastics are dominant owing to their excellent features, cost-efficiency, and versatile nature.

Based on the application, the global injection molding industry is divided into automotive, packaging, electronics, consumer goods, building & construction, and medical equipment segments.

Apparently, the automotive segment, which led the global industry share in 2023, is anticipated to account majorly towards the segmental surge in the assessment timeframe. This can be a result of the growing need for lightweight automotive features, high-volume output, and complex vehicle shapes.

On the basis of technology, the global injection molding market is bifurcated into electric injection molding, structural foam molding, thin-wall molding, hydraulic injection molding, liquid silicone injection molding, and gas-assisted injection molding segments.

Moreover, the electric injection molding segment, which led the global market share in 2023, is likely to lead the global market expansion in the forecast timeline.

The segmental surge in the coming eight years can be due to its energy efficacy, low environmental impact, and precision.

Injection Molding Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Injection Molding Market |

| Market Size in 2023 | USD 388 Billion |

| Market Forecast in 2032 | USD 562 Billion |

| Growth Rate | CAGR of 4.3% |

| Number of Pages | 222 |

| Key Companies Covered | Chen Hsong Holdings Limited, ENGEL Austria GmbH, Arburg GmbH + Co KG, Milacron Holdings Corp., oyo Machinery & Metal Co. Ltd., Haitian International Holdings Limited, Sumitomo (SHI) Demag Plastics Machinery GmbH, Husky Injection Molding Systems Ltd., KraussMaffei Group, Nissei Plastic Industrial Co. Ltd., and others. |

| Segments Covered | By Material, By Application, By Technology, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Injection Molding Market: Regional Insights

Asia-Pacific is likely to maintain leading status in the global market over the assessment timeline

Asia-Pacific, which contributed for about half of the global injection molding market size in 2023, is slated to establish a leading position in the global market in the forecast timespan.

Furthermore, the regional market expansion in the coming decade can be due to rapid economic development and industrialization in India, Thailand, Indonesia, and China.

Additionally, inexpensive labor and strong manufacturing activities will propel the regional market surge in the ensuing years. Favorable government initiatives, along with escalating customer demand, will prop up the market demand across the globe.

The North American injection molding industry is expected to register the fastest compound growth rate yearly in the expected timeline.

The elevation of the industry in the region can be a result of the presence of key automotive manufacturers in countries such as the U.S. Additionally, a rise in the focus on sustainability and advanced production capabilities will prop up the industry trends in the region.

Injection Molding Market: Competitive Space

The global injection molding market profiles key players such as:Chen Hsong Holdings Limited

- ENGEL Austria GmbH

- Arburg GmbH + Co KG

- Milacron Holdings Corp.

- oyo Machinery & Metal Co. Ltd.

- Haitian International Holdings Limited

- Sumitomo (SHI) Demag Plastics Machinery GmbH

- Husky Injection Molding Systems Ltd.

- KraussMaffei Group

- Nissei Plastic Industrial Co. Ltd.

The global injection molding market is segmented as follows:

By Material

- Plastics

- Metals

By Application

- Automotive

- Packaging

- Electronics

- Consumer Goods

- Building & Construction

- Medical Equipment

By Technology

- Structural Foam Molding

- Thin-Wall Molding

- Hydraulic Injection Molding

- Liquid Silicone Injection Molding

- Electric Injection Molding

- Gas-Assisted Injection Molding

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Injection molding is a production process for manufacturing components by injecting molten material into a mold. This process can be performed using a host of materials, such as metals, elastomers, thermosetting polymers, glasses, and thermoplastics.

The global injection molding market's growth over the forecast period can be attributed to technological innovations such as multi-component injection molding and high-speed injection molding.

According to a study, the global injection molding industry size was $388 billion in 2023 and is projected to reach $562 billion by the end of 2032.

The global injection molding market is anticipated to record a CAGR of nearly 4.3% from 2024 to 2032.

The North American injection molding industry is set to register the fastest CAGR over the forecasting timeframe owing to the presence of key automotive manufacturers in countries such as the U.S. Additionally, a rise in the focus on sustainability and advanced production capabilities will prop up the industry trends in the region.

The global injection molding market is led by players such as Chen Hsong Holdings Limited, ENGEL Austria GmbH, Arburg GmbH + Co KG, Milacron Holdings Corp., oyo Machinery & Metal Co., Ltd., Haitian International Holdings Limited, Sumitomo (SHI) Demag Plastics Machinery GmbH, Husky Injection Molding Systems Ltd., KraussMaffei Group, and Nissei Plastic Industrial Co., Ltd.

The global injection molding market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, cash-benefit analysis, market attractiveness analysis, sentiment analysis, PESTEL analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five force analysis, factor analysis, and value chain analysis. It provides an apt scenario about demand and factor conditions in the country impacting the profitability of the firms in the domestic and international markets.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed