Laser Marking Equipment Market Size, Share, Trends, Growth 2030

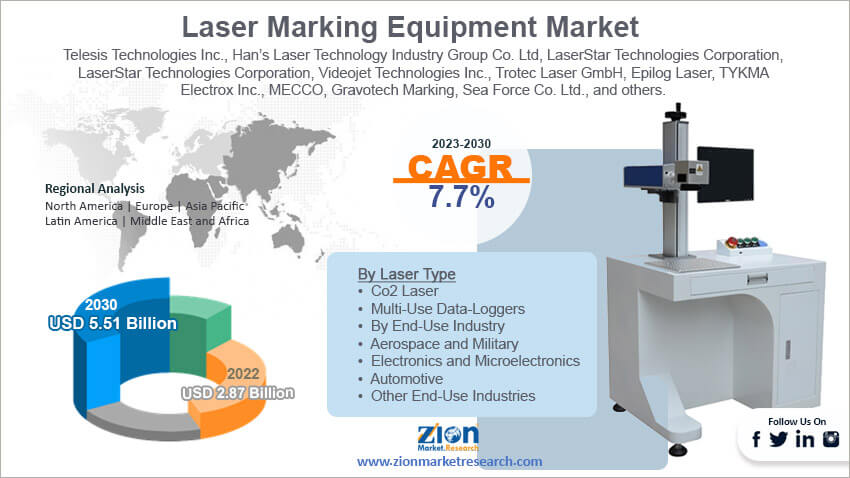

Laser Marking Equipment Market By Laser type (Co2 Laser, Fiber Laser, Green Laser, UV Laser, and YAG Laser), End-Use Industry (Aerospace & Military, Electronics & Microelectronics, Automotive, and Other End-Use Industries) By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, And Forecasts 2023 - 2030

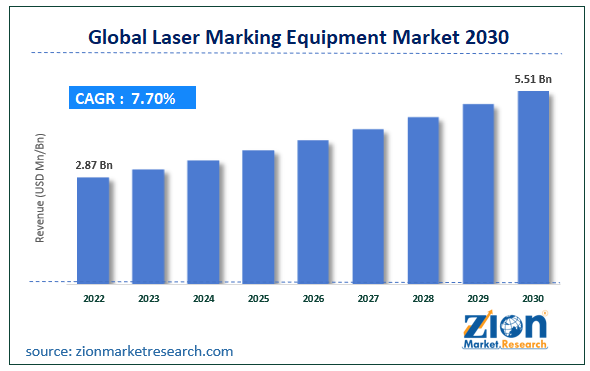

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.87 Billion | USD 5.51 Billion | 7.7% | 2022 |

Laser Marking Equipment Industry Prospective:

The global laser marking equipment market size was worth around USD 2.87 billion in 2022 and is predicted to grow to around USD 5.51 billion by 2030 with a compound annual growth rate (CAGR) of roughly 7.7% between 2023 and 2030.

Laser Marking Equipment Market: Overview

Laser marking equipment plays a pivotal role in modern manufacturing and labeling processes, offering a highly precise and efficient method for marking various materials. Using laser technology, this equipment produces permanent marks on surfaces through processes such as engraving, etching, or annealing. The versatility of laser marking enables its application across diverse industries, including automotive, electronics, medical devices, and aerospace. Its ability to create high-quality, intricate marks with exceptional accuracy makes it ideal for product branding, traceability, and ensuring compliance with industry standards. Laser marking equipment contributes to improved product identification, enhances traceability in supply chains, and facilitates customization, making it a key technology in advancing manufacturing capabilities. Furthermore, laser marking equipment is preferred for its non-contact nature, which minimizes material damage and reduces the need for consumables. The technology offers a clean and permanent marking solution, ensuring the durability and readability of marks even in challenging environments. With continuous advancements in laser technology, these marking systems are becoming more sophisticated, incorporating features like automation, increased speed, and compatibility with a wide range of materials, reinforcing their position as indispensable tools in modern manufacturing processes.

Key Insights

- As per the analysis shared by our research analyst, the global laser marking equipment industry is estimated to grow annually at a CAGR of around 7.7% over the forecast period (2023-2030).

- In terms of revenue, the global laser marking equipment market size was valued at around USD 2.87 billion in 2022 and is projected to reach USD 5.51 billion, by 2030.

- The global laser marking equipment market is projected to grow at a significant rate due to the growing demand for traceability and identification solutions across various industries.

- Based on laser type segmentation, the Co2 Laser was predicted to hold maximum market share in the year 2022.

- Based on end-use industry segmentation, aerospace and military were the leading revenue generator in 2022.

- On the basis of region, Asia Pacific was the leading revenue generator in 2022.

Request Free Sample

Request Free Sample

Laser Marking Equipment Market: Growth Drivers

Growing demand for traceability and identification solutions across various industries is propelling market growth.

The global laser marking equipment market is experiencing robust growth driven by the escalating demand for traceability and identification solutions across diverse industries. With an increasing emphasis on quality control, compliance, and supply chain management, laser marking technology has become instrumental in providing precise and permanent marking solutions for products. Industries such as automotive, aerospace, electronics, and healthcare rely on laser marking equipment to engrave unique identifiers like barcodes and serial numbers, ensuring traceability throughout the production and distribution processes. The versatility, efficiency, and durability of laser marking contribute to its widespread adoption, making it a crucial technology to meet the evolving demands of modern manufacturing and enhance overall product quality and authenticity. Moreover, as regulatory requirements become more stringent, and consumer expectations for product traceability rise, the laser marking equipment market is poised to further expand. The technology's ability to deliver high-resolution and reliable marks on various materials positions it as a key enabler for industries seeking efficient and sophisticated traceability solutions to address the complexities of today's global supply chains.

Laser Marking Equipment Market: Restraints

High initial investment associated with acquiring and implementing this technology may impede market growth.

The growth of the laser marking equipment industry is restrained by the significant initial investment required for acquiring and implementing this advanced technology. The sophisticated nature of laser marking systems, involving precision machinery and high-quality laser sources, leads to substantial upfront costs for businesses. This financial barrier can particularly impact smaller enterprises or those with limited budgets, hindering their ability to adopt laser marking solutions despite the technology's proven benefits in terms of precision marking, durability, and traceability. Additionally, the need for specialized training and expertise to operate and maintain laser marking equipment adds to the overall cost of implementation, further limiting the widespread adoption of this technology. As the market addresses these cost-related challenges and technological advancements lead to more cost-effective solutions, the potential for broader adoption of laser marking equipment could increase, driving market growth.

Laser Marking Equipment Market: Opportunities

Snowballing demand for laser marking in additive manufacturing or 3D printing applications to provide growth opportunities

The burgeoning demand for laser marking in additive manufacturing or 3D printing applications presents a significant growth opportunity for the laser marking equipment market. As industries such as aerospace, healthcare, and automotive increasingly adopt 3D printing technology for manufacturing intricate and customized components, there arises a complementary need for precise and permanent marking on these complex structures. Laser marking technology, with its non-contact and high-precision capabilities, is well-suited for adding essential identifiers like serial numbers and barcodes to intricate 3D-printed parts without compromising their structural integrity. The integration of laser marking solutions into additive manufacturing processes not only enhances traceability but also facilitates customization and personalization of 3D-printed products. This trend aligns with the broader industry shift towards more sophisticated and individualized manufacturing approaches. As the 3D printing sector continues to grow and diversify, the demand for laser marking equipment to meet the specific requirements of this application is poised to increase, providing manufacturers with opportunities to innovate and expand their market presence.

Laser Marking Equipment Market: Challenges

Ongoing need to address environmental concerns related to the materials used in the process to challenge market growth

A substantial challenge facing the laser marking equipment industry is the persistent need to address environmental concerns associated with the materials used in the marking process. Traditional laser marking methodologies often involve the utilization of inks, coatings, or additives that may contain hazardous substances, raising ecological and health considerations. With an increasing global emphasis on sustainability and environmentally friendly practices, industries are under pressure to adopt greener alternatives in laser marking. However, developing eco-friendly solutions that not only adhere to stringent environmental standards but also maintain the high precision and efficiency expected from laser marking poses a significant challenge. Overcoming this challenge is crucial for the industry to navigate evolving regulations, meet consumer demands for sustainable practices, and align with corporate sustainability objectives. Ongoing research and innovation will be imperative to devise environmentally responsible laser marking processes that ensure both operational excellence and ecological integrity, paving the way for sustainable market growth.

Laser Marking Equipment Market: Segmentation

The global laser marking equipment market is segmented based on laser type, technology laser type, end-use industry, and region.

Based on laser type, the global market segments are Co2 Laser, Fiber Laser, Green Laser, UV Laser, and YAG Laser. At present, the global market is dominated by the Co2 Laser segment. The dominance of this segment is primarily due to its versatility and widespread application in various industries. Co2 lasers are known for their ability to mark a wide range of materials, including plastics, glass, and certain metals, offering high precision and legibility. Their efficiency, cost-effectiveness, and capability to produce durable marks contribute to their popularity, making Co2 lasers the preferred choice for a diverse array of marking applications across industries such as electronics, automotive, and packaging.

Based on end-use industry, the global laser marking equipment industry is categorized as aerospace & military, electronics & microelectronics automotive, and others. Out of these, aerospace and military was the largest shareholding segment in the global market. This dominance is attributed to the critical role of laser marking in these industries for precise part identification, traceability, and compliance with stringent regulations. The aerospace and military sector relies on laser marking for a wide range of applications, from marking components for assembly to ensuring the authenticity and traceability of critical parts throughout their lifecycle. The high precision, durability, and non-contact nature of laser marking make it an essential technology in these safety-critical industries.

Laser Marking Equipment Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Laser Marking Equipment Market |

| Market Size in 2022 | USD 2.87 Billion |

| Market Forecast in 2030 | USD 5.51 Billion |

| Growth Rate | CAGR of 7.7% |

| Number of Pages | 225 |

| Key Companies Covered | Telesis Technologies Inc., Han’s Laser Technology Industry Group Co. Ltd, LaserStar Technologies Corporation, LaserStar Technologies Corporation, Videojet Technologies Inc., Trotec Laser GmbH, Epilog Laser, TYKMA Electrox Inc., MECCO, Gravotech Marking, Sea Force Co. Ltd., and others. |

| Segments Covered | By Laser Type, By End-Use Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Laser Marking Equipment Market: Regional Analysis

Asia Pacific to lead the market during the forecast period

Asia Pacific is poised to take the lead in the global laser marking equipment market during the forecast period, driven by a convergence of factors that underscore the region's robust industrial growth and technological advancements. The rapid expansion of manufacturing sectors in countries such as China and India, coupled with the increasing adoption of automation and advanced production technologies, contributes significantly to the demand for laser marking equipment. As industries in the region emphasize precision marking for traceability and compliance, the versatility and efficiency of laser marking technology become instrumental, further fueling its widespread adoption. Moreover, the Asia Pacific market benefits from the flourishing electronics, automotive, and healthcare sectors, all of which have a substantial need for laser marking applications. The region's economic dynamism, coupled with the continuous modernization of manufacturing practices, positions Asia Pacific as a key player in the laser marking equipment market. As industries in this region increasingly prioritize innovation and efficiency, the demand for high-precision marking solutions is expected to drive substantial market growth, making the Asia Pacific a focal point for the expansion of the laser marking equipment market.

Key Developments

In September 2023, Gravotech announced the launch of a new line of compact laser marking machines. These new machines will be designed to be easy to use and to be able to be used in a variety of applications.

In June 2023, Trumpf announced the launch of a new line of ultrashort pulse lasers. These new lasers will be used for a variety of applications, including marking on metal, plastic, and glass.

Laser Marking Equipment Market: Competitive Analysis

The global laser marking equipment market is dominated by players like:

- Telesis Technologies, Inc.

- Han’s Laser Technology Industry Group Co., Ltd

- LaserStar Technologies Corporation

- Videojet Technologies, Inc.

- Trotec Laser GmbH

- Epilog Laser

- TYKMA Electrox, Inc.

- MECCO

- Gravotech Marking

- Sea Force Co., Ltd

The global laser marking equipment market is segmented as follows:

By Laser Type

- Co2 Laser

- Multi-Use Data-Loggers

By End-Use Industry

- Aerospace and Military

- Electronics and Microelectronics

- Automotive

- Other End-Use Industries

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Laser marking equipment plays a pivotal role in modern manufacturing and labeling processes, offering a highly precise and efficient method for marking various materials. Using laser technology, this equipment produces permanent marks on surfaces through processes such as engraving, etching, or annealing.

The global laser marking equipment market cap may grow owing to the due to growing demand for traceability and identification solutions across various industries.

According to study, the global laser marking equipment market size was worth around USD 2.87 billion in 2022 and is predicted to grow to around USD 5.51 billion by 2030.

The CAGR value of the laser marking equipment market is expected to be around 7.7% during 2023-2030.

The global laser marking equipment market growth is expected to be driven by Asia Pacific. It is currently the world’s highest revenue-generating market owing to the established manufacturing sectors and booming flourishing electronics, automotive, and healthcare sectors sector.

The global laser marking equipment market is led by players Telesis Technologies, Inc., Han’s Laser Technology Industry Group Co., Ltd, LaserStar Technologies Corporation, LaserStar Technologies Corporation, Videojet Technologies, Inc., Trotec Laser GmbH, Epilog Laser, TYKMA Electrox, Inc., MECCO, Gravotech Marking, and Sea Force Co., Ltd.

The report analyzes the global laser marking equipment market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the laser marking equipment industry.

Choose License Type

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed