Metal Molds Market Size, Share, Trends, Growth and Forecast 2030

Metal Molds Market By Manufacturing Process (Electric Discharge Machining And Standard/ CNC Machining), By Material (Aluminum, Steel, And Others), By Application (Medical, Automotive, Construction, Packaging, Electronics, And Others), And By Region - Global And Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, And Forecasts 2023-2030-

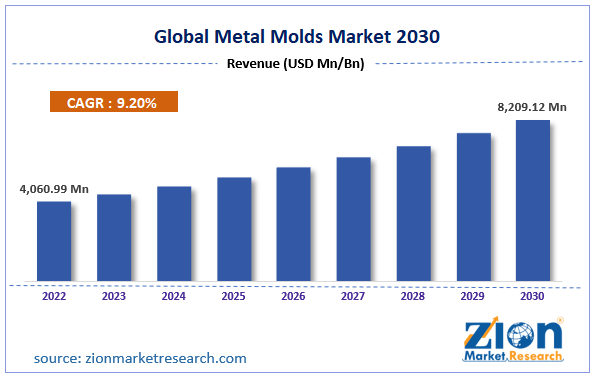

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 4,060.99 million | USD 8,209.12 million | 9.20% | 2022 |

Description

The global metal molds market size was worth around USD 4,060.99 million in 2022 and is predicted to grow to around USD 8,209.12 million by 2030 with a compound annual growth rate (CAGR) of roughly 9.20% between 2023 and 2030.

Global Metal Molds Market For Plastic Injection Molding: Overview

While the aftermath of the COVID-19 pandemic has been wreaking havoc across numerous industries, other industrial sectors such as the medical and pharma sectors have been gaining considerably from the opportunity. The global metal molds market for plastic injection molding is one such industry, wherein a hallow metal block is injected with molten plastic for achieving a particular shape, otherwise known as a mold.

Generally made from pre-hardened or hardened aluminum, steel, and beryllium-copper alloy, these molds, when made from steel, are designed for processing more than a million parts during their lifespan.

Aluminum molds, although cheaper than their steel counterparts, can be ill-suited for bulk production capabilities. Nevertheless, the utilization of electrical discharge machines (EDMs) or computer numerical control for building aluminum molds can boost productivity of these molds.

Global Metal Molds Market For Plastic Injection Molding: Growth Factors

The growing volume of demand from the automotive sector has been a major growth factor of the global metal molds for plastic injection molding market. Leading international OEMs have been seeking to replace plastics with metals in the wake of the increasing stringency of government regulations for protecting the environment.

They can also lower the overall weight of automobiles and boost fuel efficiency at the same time when metal components are replaced with identical plastic parts. The adoption of injection molding of plastic components is an ideal solution as mass production of uniform and high-quality components is possible using the technique. This has been facilitating the expansion of the global metal molds market for injection molding.

The packaging industry is another major application segment in the market, which is poised for magnificent expansion through 2026. The consistent surge in the demand for small consumer goods, consumer electronics, food & beverage, and medica & pharmaceutical products has been harnessing opportunities across the global market for metal molds for plastic injection molding.

Additionally, the introduction of new and improved food grade plastic materials for application across the food & beverage and pharmaceutical industry can significantly induce higher demand for these tools & equipment. The lower risk of manufacturing defects and errors is the prime reason for the rising adoption of this equipment by the leading retailers and manufacturers on a global scale.

Global Metal Molds Market For Plastic Injection Molding: Segmentation

The global metal molds market for plastic injection molding can be segregated by manufacturing process, by material, by application, and by region. On the basis of manufacturing process, the global metal molds market for plastic injection molding has been bifurcated into electric discharge machining and standard/ CNC machining. Based on material, the global metal molds market for plastic injection molding is categorized into aluminum, steel, and others.

On the basis of application, the global metals molds market for plastic injection molding has been differentiated into medical, automotive, construction, packaging, electronics, and others. Packaging has been further sub-segmented as food & beverage, beauty & personal care, pharmaceutical, and others. The food & beverage sector can account for the dominant portion of the overall market share by 2026.

Metal Molds Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Metal Molds Market Research Report |

| Market Size in 2022 | USD 4,060.99 million |

| Market Forecast in 2030 | USD 8,209.12 million |

| Growth Rate | CAGR of 9.20% |

| Number of Pages | 214 |

| Key Companies Covered | Enko AS, Bunty LLC, Colonial Machine, JBJ Technologies Ltd., Wayken Rapid Manufacturing Limited, GENSINI S.R.L., Engel Austria GmbH, Forum Plastics LLC, Jade Group INTL, MSI Mold Builders, ERMO S.A., The Rodon Group, Bericap GmbH & Co. KG, Michiana Global Mold Inc., CS Tool & Engineering, Troqueles y Moldes de Galicia, S.A. (Tromosa), Accede Mold & Tool Co. Inc., and Intertech |

| Segments Covered | By Manufacturing Process, By Material, By Application, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Metal Molds Market For Plastic Injection Molding: Regional Analysis

The metal molds market for plastic injection molding in Asia Pacific is expected to garner considerable pace through the assessment period, triggered by the growing bulk of government subsidies and tax benefits provided to manufacturers across the region. With the boom across the industrial sector in the region, numerous personal care, consumer electronics, automobile, and manufacturing companies have been seeking efficient packaging systems.

The North America metal molds market for plastic injection molding is set to garner considerable demand for injection molding, as the preference for high-end automobiles has been escalating. With the adoption of cutting-edge technologies across the industrial sector in the region, the market is expected to gain prominence by 2026, supported by government initiatives and private funding.

Global Metal Molds Market For Plastic Injection Molding: Competitive Players

- Enko AS

- Bunty LLC

- Colonial Machine

- JBJ Technologies Ltd.

- Wayken Rapid Manufacturing Limited

- GENSINI S.R.L.

- Engel Austria GmbH

- Forum Plastics LLC

- Jade Group INTL

- MSI Mold Builders

- ERMO S.A.

- The Rodon Group

- Bericap GmbH & Co. KG

- Michiana Global Mold Inc.

- CS Tool & Engineering

- Troqueles y Moldes de Galicia

- S.A. (Tromosa)

- Accede Mold & Tool Co. Inc.

- Intertech

Global Metal Molds Market For Plastic Injection Molding: Segment Analysis

By Manufacturing Process

- Electric Discharge Machining

- Standard/ CNC Machining

By Material

- Aluminum

- Steel

- Others

By Application

- Medical

- Automotive

- Construction

- Packaging

- Electronics

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Choose License Type

List of Contents

Global Market For Plastic Injection Molding: OverviewGlobal Market For Plastic Injection Molding: Growth FactorsGlobal Market For Plastic Injection Molding: SegmentationReport ScopeGlobal Market For Plastic Injection Molding: Regional AnalysisGlobal Market For Plastic Injection Molding: Competitive PlayersGlobal Market For Plastic Injection Molding: Segment AnalysisFrequentlyAsked Questions

Metal molds, also known as metal dies or metal tooling, are specialized tools or forms made of steel or aluminum used in metal casting, injection molding, and metal shaping. Metal molds are essential for precision and consistency in molding and manufacturing many goods.

The metal molds market accounted for USD 4,060.99 million in 2022 and is expected to reach USD 8,209.12 million by 2030.

The CAGR value of the metal molds market is expected to be around 9.20% during 2023-2030.

The metal molds market for plastic injection molding in Asia Pacific is expected to garner considerable pace through the assessment period, triggered by the growing bulk of government subsidies and tax benefits provided to manufacturers across the region. With the boom across the industrial sector in the region, numerous personal care, consumer electronics, automobile, and manufacturing companies have been seeking efficient packaging systems.

Some key players of the global metal molds market are Enko AS, Bunty LLC, Colonial Machine, JBJ Technologies Ltd., Wayken Rapid Manufacturing Limited, GENSINI S.R.L., Engel Austria GmbH, Forum Plastics LLC, Jade Group INTL, MSI Mold Builders, ERMO S.A., The Rodon Group, Bericap GmbH & Co. KG, Michiana Global Mold Inc., CS Tool & Engineering, Troqueles y Moldes de Galicia, S.A. (Tromosa), Accede Mold & Tool Co. Inc., and Intertech

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed