Molded Underfill Material Market Trend, Share, Growth, Size Analysis and Forecast 2030

Molded Underfill Material Market By Application (Flip Chips, Ball Grid Array, and Chip Scale Packaging), By Type (Thermal Mechanical Analyzer Technology and Dynamic Mechanical Analyzer Technology), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

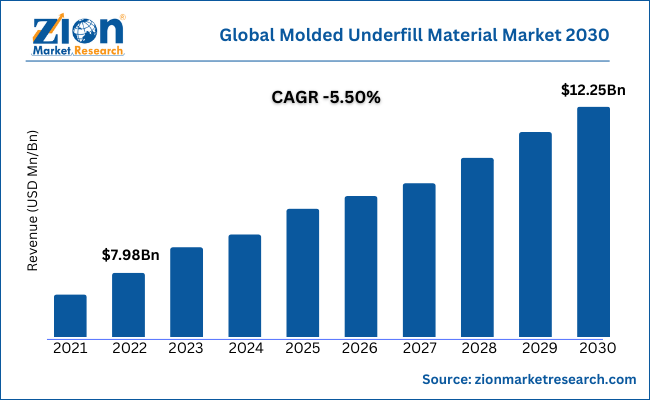

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 7.98 Billion | USD 12.25 Billion | 5.50% | 2022 |

Industry Prospective:

The global molded underfill material market size was worth around USD 7.98 billion in 2022 and is predicted to grow to around USD 12.25 billion by 2030 with a compound annual growth rate (CAGR) of roughly 5.50% between 2023 and 2030. The report analyzes the global molded underfill material market drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the molded underfill material industry.

Molded underfill material Market: Overview

Molded underfill material (MUF) is an encapsulant that is used extensively in the semiconductor industry where it is used to protect and reinforce the connections that exist between printed circuit boards (PCBs) and integrated circuits (ICs). This resin-based material is injected in the gap between the PCB and the IC after the latter has been attached to the board. Once the process of curing is completed, the structure solidifies leading to the creation of a rigid protective layer around the integrated circuit. MUF derives its name as molded underfill since the protective covering is first molded in a specific shape before application. The shape is determined by the exact fit and the dimension of the IC along with the surrounding PCB components. The molded underfill material industry deals with the production and distribution of molded underfill material across end-users in the semiconductor sector. During the forecast period, the demand is expected to be led by several favorable factors.

Key Insights:

- As per the analysis shared by our research analyst, the global molded underfill material market is estimated to grow annually at a CAGR of around 5.50% over the forecast period (2023-2030)

- In terms of revenue, the global molded underfill material market size was valued at around USD 7.98 billion in 2022 and is projected to reach USD 12.25 billion, by 2030.

- The molded underfill material market is projected to grow at a significant rate due to the growth in the semiconductor industry

- Based on application segmentation, flip chips were predicted to show maximum market share in the year 2022

- Based on type segmentation, dynamic mechanical analyzer technology was the leading type in 2022

- On the basis of region, North America was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Molded underfill material Market: Growth Drivers

Growth in the semiconductor industry to act as a major growth propeller

The global molded underfill material market is projected to grow owing to the rapidly rising semiconductor industry across the world. The high rate is fueled by the increasing consumption of electronic devices that have become an inseparable part of the modern technology-driven world. In addition to this, companies operating in the electronic device sector are investing more resources including monetary and non-monetary toward introducing new technology which could lead to more demand for efficient molded underfill material as the semiconductor industry reaches new heights. Furthermore, the growing advancements in technology related to MUF could result in higher revenue. This is mainly due to the invention of new and integrated ICs that are smaller but more complex in design leading to the growing use of encapsulation materials that allow protection against mechanical stress and temperature variations on ICs.

Molded underfill material Market: Restraints

High cost of MUF production to restrict the market growth

The global molded underfill material industry is projected to come across certain growth challenges owing to the high cost associated with the production and application of molded underfill materials. These encapsulation units are specialized materials and hence require advanced processing techniques. They also demand assistance from an expert and skilled professionals. Moreover, raw materials used in the production of MUF must be of high quality. All of these factors in combination impact the overall price of the component which is a crucial growth limitation as it can greatly encourage companies to look for cheaper substitutes.

Molded underfill material Market: Opportunities

Increasing adoption of the Internet of Things (IoT) to provide growth opportunities

The global molded underfill material market can expect several growth opportunities owing to the increasing adoption of the Internet of Things (IoT) which refers to the concept of connecting everyday devices and objects to the Internet. This allows them to communicate with each other and exchange data. The devices operating on IoT are embedded with sensors, software, and connectivity which facilitates its function. Some examples of everyday IoT-powered devices are thermostats, security cameras, and lighting systems, wearable fitness trackers, connected cars, and industrial machines.

Molded underfill material Market: Challenges

Associated technical complexity to challenge market growth

The application of MUF requires the use of a special injection molding process which is known to be severely technically challenging. It can only be performed with the assistance of an expert and with the use of specialized equipment. These factors could lead to challenges against global molded underfill material industry expansion as it can limit the entry of new players. Furthermore, the growing concerns over the compatibility of MUF with all types of IC and PCB designs is another roadblock that restricts market revenue.

Molded underfill material Market: Segmentation

The global molded underfill material market is segmented based on application, type, and region.

Based on application, the global market segments are flip chips, ball grid array, and chip scale packaging. The most common application of molded underfill material is in the flip chips segment due to the increasing popularity of flip chip packages in the semiconductor sector. They are smaller in size but high in performance. They do not consume much power as compared to traditional wire-bonded packages. The flip chip packaging process includes directly attaching IC die to the PCB or the substrate with the aid of solder bumps. Once the process is complete, MUF is injected around the die. This provides mechanical support and protection against thermal and mechanical stresses. The World Semiconductor Trade Statistics (WSTS) organization, stated that the global semiconductor market was worth $522.5 billion in 2021.

Based on type, the global market segments are thermal mechanical analyzer technology and dynamic mechanical analyzer technology. In 2022, the molded underfill material industry witnessed the highest growth in dynamic mechanical analyzer technology (DMA) mainly due to its versatility and wider range of applications. This technology can be used to measure the dynamic mechanical properties of materials such as temperatures, frequencies, and deformations. They are also used to study the several viscoelastic behaviors of materials like modulus, damping, and creep. The thermal mechanical analyzer has higher applications in understanding more thermal aspects of the unit. As per the International Telecommunication Union (ITU), more than 4.9 billion people were using mobile phones in 2021.

Recent Developments:

- In March 2023, Transphorm Inc., a leading supplier of high-performance and highly reliable gallium nitride (GaN) power conversion products announced a partnership with Weltrend Semiconductor Inc that deals with adapter USB Power Delivery (PD) Controller Integrated Circuits (ICs). The companies in a joint move unveiled GaN System-in-Package (SiP). The new IC offers 93% better power efficiency as compared to its contemporaries

- In January 2023, NXP Semiconductors, a Dutch semiconductor company, announced the inauguration of its new and state-of-the-art facility research & development laboratory in Bengaluru, India, thus giving the economy a much-needed boost. The Union Ministry of India is pushing the country’s semiconductor ecosystem

Molded underfill material Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Molded Underfill Material Market Research Report |

| Market Size in 2022 | USD 7.98 Billion |

| Market Forecast in 2030 | USD 12.25 Billion |

| Growth Rate | CAGR of 5.50% |

| Number of Pages | 211 |

| Key Companies Covered | Henkel AG & Co. KGaA, NAMICS Corporation, Won Chemical Co., Ltd., Namics Technologies, Inc., Zymet, Inc., Sumitomo Bakelite Co., Ltd., Hitachi Chemical Company, Ltd., Indium Corporation, Master Bond Inc., KYOCERA Corporation, Epoxy Technology, Inc., Panasonic Corporation, Nitto Denko Corporation, Tanaka Chemical Corporation, Mitsui Chemicals, Inc., H.B. Fuller Company, Dymax Corporation, Shenzhen Shengxin Automation Equipment Co., Ltd., NXP Semiconductors N.V., Intel Corporation, Texas Instruments Inc., Samsung Electronics Co., Ltd., Broadcom Inc., Advanced Micro Devices, Inc., and Qualcomm Inc. |

| Segments Covered | By Application, By Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Molded underfill material Market: Regional Analysis

North America to witness massive growth rate

The global molded underfill material market is expected to witness the highest growth in North America with the US leading with the largest part of the regional share. One of the leading causes of growth is the high demand for advanced packaging solutions in the electronics industry which is further strengthened by the presence of several key players in the market.

In Europe, the growth rate may be the result of increasing demand for miniaturization of electronic devices along with rising investments in the semiconductor industry. Furthermore, the growing use of ICs and PCBs in the ever-evolving regional automotive electronics sector could also work in favor of regional expansion.

Asia-Pacific is expected to become the fastest-growing region during the forecast period with China, India, and Japan acting as major contributors.

Molded underfill material Market: Competitive Analysis

The global molded underfill material market is led by players like:

- Henkel AG & Co. KGaA

- NAMICS Corporation

- Won Chemical Co. Ltd.

- Namics Technologies Inc.

- Zymet Inc.

- Sumitomo Bakelite Co. Ltd.

- Hitachi Chemical Company Ltd.

- Indium Corporation

- Master Bond Inc.

- KYOCERA Corporation

- Epoxy Technology Inc.

- Panasonic Corporation

- Nitto Denko Corporation

- Tanaka Chemical Corporation

- Mitsui Chemicals Inc.

- H.B. Fuller Company

- Dymax Corporation

- Shenzhen Shengxin Automation Equipment Co. Ltd.

- NXP Semiconductors N.V.

- Intel Corporation

- Texas Instruments Inc.

- Samsung Electronics Co. Ltd.

- Broadcom Inc.

- Advanced Micro Devices Inc.

- Qualcomm Inc.

The global molded underfill material market is segmented as follows:

By Application

- Flip Chips

- Ball Grid Array

- Chip Scale Packaging

By Type

- Thermal Mechanical Analyzer Technology

- Dynamic Mechanical Analyzer Technology

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Molded underfill material (MUF) is an encapsulant that is used extensively in the semiconductor industry where it is used to protect and reinforce the connections that exist between printed circuit boards (PCBs) and integrated circuits (ICs).

The global molded underfill material market is projected to grow owing to the rapidly rising semiconductor industry across the world.

According to study, the global molded underfill material market size was worth around USD 7.98 billion in 2022 and is predicted to grow to around USD 12.25 billion by 2030.

The CAGR value of molded underfill material market is expected to be around 5.50% during 2023-2030

The global molded underfill material market is expected to witness the highest growth in North America with the US leading with the largest part of the regional share.

The global molded underfill material market is led by players like Henkel AG & Co. KGaA, NAMICS Corporation, Won Chemical Co., Ltd., Namics Technologies, Inc., Zymet, Inc., Sumitomo Bakelite Co., Ltd., Hitachi Chemical Company, Ltd., Indium Corporation, Master Bond Inc., KYOCERA Corporation, Epoxy Technology, Inc., Panasonic Corporation, Nitto Denko Corporation, Tanaka Chemical Corporation, Mitsui Chemicals, Inc., H.B. Fuller Company, Dymax Corporation, Shenzhen Shengxin Automation Equipment Co., Ltd., NXP Semiconductors N.V., Intel Corporation, Texas Instruments Inc., Samsung Electronics Co., Ltd., Broadcom Inc., Advanced Micro Devices, Inc., and Qualcomm Inc.

Choose License Type

List of Contents

Industry Prospective:Molded underfill material OverviewKey Insights:Molded underfill material Growth DriversMolded underfill material RestraintsMolded underfill material OpportunitiesMolded underfill material ChallengesMolded underfill material SegmentationRecent Developments:Molded underfill material Report ScopeMolded underfill material Regional AnalysisMolded underfill material Competitive AnalysisThe global molded underfill material market is segmented as follows:By RegionHappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed