Permanent Magnet Motor Market Size, Share, Trends, Growth 2028

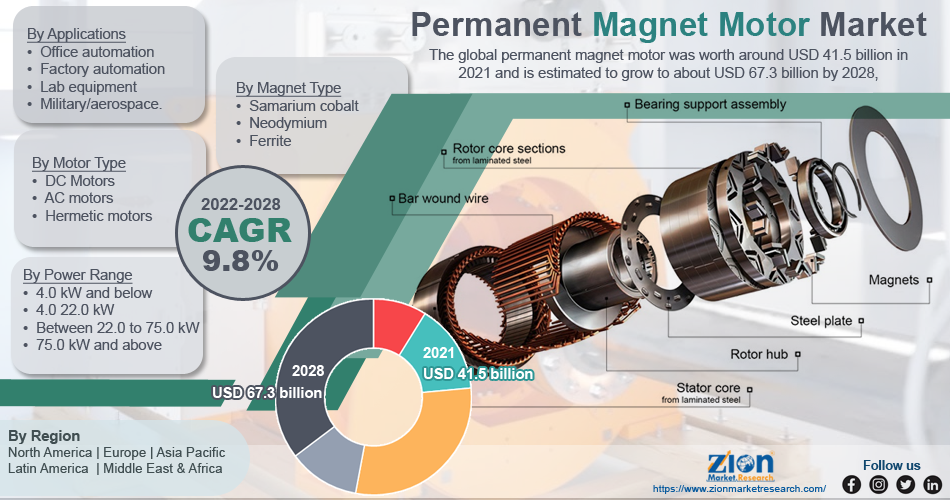

Permanent Magnet Motor Market By Motor Type (AC motors, DC Motors, Hermetic motors), By Magnet Type (Neodymium, Samarium Cobalt, Ferrite), By Power Range (4.0 kW and Below, Between 4.0 22.0 kW, Between 22.0 75.0 kW, 75.0 kW and Above), By Applications (Factory Automation, Office Automation, Lab Equipment, Military/Aerospace) and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data and Forecasts 2022 - 2028

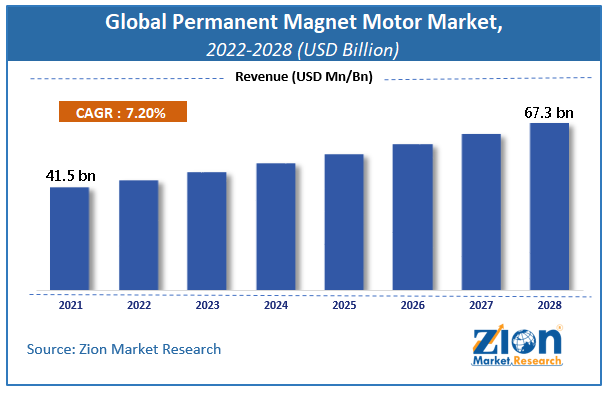

| Market Size in 2021 | Market Forecast in 2028 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 41.5 Billion | USD 67.3 Billion | 9.8% | 2021 |

Permanent Magnet Motor Industry Prospective:

The global permanent magnet motor market was worth around USD 41.5 billion in 2021 and is estimated to grow to about USD 67.3 billion by 2028, with a compound annual growth rate (CAGR) of approximately 9.8 percent over the forecast period.

The report analyzes the permanent magnet motor market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the permanent magnet motor market.

Permanent Magnet Motor Market: Overview

A permanent magnet motor is an electric motor with permanent magnets as well as windings on its field, rather than only windings. The basic operation of a permanent magnet motor is similar to that of other electric motors, the outer stator houses windings of coils fed by a power source, and the rotor revolves freely thanks to the forces given by the stator coils. Permanent magnet motors come in bigger sizes, have more horsepower, and may compete with induction motors in terms of strength, efficiency, and a number of applications.

COVID-19 Impact:

Due to the COVID-19 pandemic, supply chains may feel the most substantial near-term consequences on permanent magnet motors that are already contracted or in the production process. Industry leaders expect supply and construction delays, either as a result of industry closures to prevent the spread of the coronavirus or as a result of workers being ill. Many of the components and parts used in the manufacture of permanent magnet motors are sourced from Europe, China, Asia Pacific, and portions of Europe.

Manufacturing interruptions in China and the United States may cause the permanent magnet motor industry to see a severe short-term drop. Furthermore, several nations' domestic currencies have declined as a result of the COVID-19 pandemic. There is a mismatch of supply and demand, which results in financial losses for metal manufacturers; also, critical components required in the construction of permanent magnet motors are often acquired in US dollars, which might result in higher component costs.

To know more about this report, request a sample copy.

Permanent Magnet Motor Market: Growth Drivers

Increasing demand for energy-efficient and low-cost maintenance synchronized motors across different industries is likely to drive market growth.

Permanent magnet synchronized motors are significantly more efficient than induction motors, and they are the most power-dense traction motors on the market. As a result, the growing need for higher-efficiency motors is projected to fuel the demand for permanent magnet synchronous motors in a variety of sectors. Permanent magnet motors are used in most sectors, including electronics, textiles, and pulp & paper, to provide higher-functioning goods with more functionality (for instance, silent washing machines & fans, and improved low voltage to allow solar water pumps and deliver better performance on overcast days).

Permanent magnet motors are also being considered for HVAC applications in the residential and commercial sectors. Permanent magnet synchronous motors are predicted to be used in the majority of electric cars in the future (about 80 percent). Appliances with efficient permanent magnet motors consume 20-40 percent less energy than those with traditional alternating current motors. PM motors are also more dependable than traditional motors, which is a critical feature for appliances built for usage in off-grid or rural settings. These distinct qualities boost customer satisfaction in off-grid and weak-grid markets, encouraging them to spend more for higher-performing appliances.

Permanent Magnet Motor Market: Restraints

The high cost of permanent magnet motors may hinder the growth of the market

The increased cost of permanent magnet motors is one of the key constraints limiting their expansion. Permanent magnet motors are highly efficient, although they are expensive due to the usage of rare-earth magnets. Although some industrial and commercial electronics manufacturers are hesitant to invest in permanent magnet motors, this trend is expected to alter in the future period, as permanent magnet motors reduce maintenance costs, improving operations in both the industrial & commercial sectors and resulting in increased productivity.

Permanent Magnet Motor Market: Opportunities

The adoption of cost-effective ferrite permanent magnets offers significant opportunities for the market expansion

Permanent magnets made of rare-earth materials, which are extensively employed in permanent magnet motors, are costly. This is because pricey neodymium or samarium-cobalt magnets are used. As a result, ferrite magnets are employed to make low-cost permanent magnet motors. In addition, to be cost-effective, these ferrite permanent magnets are readily accessible in China and offer minimal current losses in low-frequency applications like motor drives. A motor using ferrite magnets, on the other hand, is expected to have roughly 30-50 percent of the power density of a rare-earth motor. Due to the high expense of rare-earth magnets, several industries are looking for ways to employ ferrites instead. The demand for ferrite permanent magnet motors is projected to increase as a result of this reason.

Permanent Magnet Motor Market Report Scope:

| Report Attributes | Report Details |

|---|---|

| Report Name | Permanent Magnet Motor Market Research Report |

| Market Size in 2021 | USD 41.5 Billion |

| Market Forecast in 2028 | USD 67.3 Billion |

| Compound Annual Growth Rate | CAGR of 9.8% |

| Number of Pages | 166 |

| Forecast Units | Value (USD Billion), and Volume (Units) |

| Key Companies Covered | ABB, Siemens, Rockwell Automation, Nidec Corporation, Johnson Electric, Wolong Electric, WEG, Allied Motion, AMETEK, Toshiba, Regal Beloit, Yaskawa, Liebherr, Faulhaber, TECO, Dumore, Kolmorgen, Electrocraft, Cartermotor Company, and Mark Elektriks |

| Segments Covered | By Motor Type, By Magnet Type, By Power Range, By Applications And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East and Africa (MEA) |

| Countries Covered | North America: U.S and Canada Europe: Germany, Italy, Russia, U.K, Spain, France, Rest of Europe APAC: China, Australia, Japan, India, South Korea, South East Asia, Rest of Asia Pacific Latin America: Brazil, Argentina, Chile The Middle East And Africa: South Africa, GCC, Rest of MEA |

| Base Year | 2021 |

| Historical Year | 2016 to 2020 |

| Forecast Year | 2022 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Permanent Magnet Motor Market: Challenges.

Availability of inexpensive and low-quality electric motors in local markets poses a great challenge to the market.

With a large number of local and foreign companies, the permanent magnet motors industry is extremely fragmented. The regulated market mostly caters to industrial clients and maintains high product quality, whereas the unorganized market provides low-cost options for tapping local markets. In most countries, local makers of electric motors target the unorganized sector and fight fiercely with global suppliers in their marketplaces. Unorganized competitors offering low-cost, low-quality electric motors are presently posing a significant threat to industry leaders. This poses a significant impediment to the global permanent magnet motor market's expansion.

Permanent Magnet Motor Market: Segmentation

The global permanent magnet motor market is categorized into motor type, magnet type, power range, applications, and region. Based on motor type, the market is bifurcated into DC Motors, AC motors, and Hermetic motors. The magnet-type segment of the market is categorized into samarium cobalt, neodymium, and ferrite. By power range, the global permanent magnet motor market is divided into 4.0 22.0 kW, 4.0 kW & below, between 22.0 75.0 kW, and 75.0 kW and above. The application segment of the market comprised office automation, factory automation, lab equipment, and military/aerospace.

Recent Developments

- In December 2019, Rockwell Automation has introduced control of permanent magnet motors to its Powerflex 755T Drives series, extending the power ranges and functionalities of its TotalFORCE technology for industrial drives.

- In May 2020, Nidec Leroy-Somer launches Dyneo+, its new series of ultra-premium performance permanent magnet-assisted synchronous reluctance motors.

Permanent Magnet Motor Market: Regional Landscape

During the projection period of 2022 to 2028, Asia Pacific is expected to be the biggest share in the global permanent magnet motor market. The permanent magnet motor market in the Asia Pacific is growing as a result of increased investments in the automotive industry, particularly electric cars, and increased electronics production in the area. Furthermore, nations like China, Japan, and India are propelling the region's permanent magnet motor market forward. North America and Europe combinedly hold more than 55 percent of the market share.

Permanent Magnet Motor Market: Competitive Landscape

Key players functioning in the global permanent magnet motor market include

- ABB

- Siemens

- Rockwell Automation

- Nidec Corporation

- Johnson Electric

- Wolong Electric

- WEG

- Allied Motion

- AMETEK

- Toshiba

- Regal Beloit

- Yaskawa

- Liebherr

- Faulhaber

- TECO

- Dumore

- Kolmorgen

- Electrocraft

- Cartermotor Company

- Mark Elektriks

The global permanent magnet motor market is segmented as follows:

By Motor Type

- DC Motors

- AC motors

- Hermetic motors

By Magnet Type

- Samarium cobalt

- Neodymium

- Ferrite

By Power Range

- 4.0 kW and below

- 4.0 22.0 kW

- Between 22.0 to 75.0 kW

- 75.0 kW and above

By Applications

- Office automation

- Factory automation

- Lab equipment

- Military/aerospace.

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Increasing demand for energy-efficient and low-cost maintenance synchronized motors across different industries is likely to drive market growth. Permanent magnet synchronized motors are significantly more efficient than induction motors, and they are the most power-dense traction motors on the market. As a result, the growing need for higher-efficiency motors is projected to fuel the demand for permanent magnet synchronous motors in a variety of sectors.

According to the Zion Market Research report, the global permanent magnet motor market was worth about 41.5 (USD billion) in 2021 and is predicted to grow to around 67.3 (USD billion) by 2028, with a compound annual growth rate (CAGR) of around 9.8 percent.

During the projection period of 2022 to 2028, Asia Pacific is expected to be the biggest market. The permanent magnet motor market in the Asia Pacific is growing as a result of increased investments in the automotive industry, particularly electric cars, and increased electronics production in the area. Furthermore, nations like China, Japan, and India are propelling the region's permanent magnet motor market forward. North America and Europe combinedly holds more than 55 percent of the market share.

Key players functioning in the global permanent magnet motor market include ABB, Siemens, Rockwell Automation, Nidec Corporation, Johnson Electric, Wolong Electric, WEG, Allied Motion, AMETEK, Toshiba, Regal Beloit, Yaskawa, Liebherr, Faulhaber, TECO, Dumore, Kolmorgen, Electrocraft, Cartermotor Company, and Mark Elektriks.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed