Plastic Resins Market Trend, Share, Growth, Demand, Size and Forecast 2032

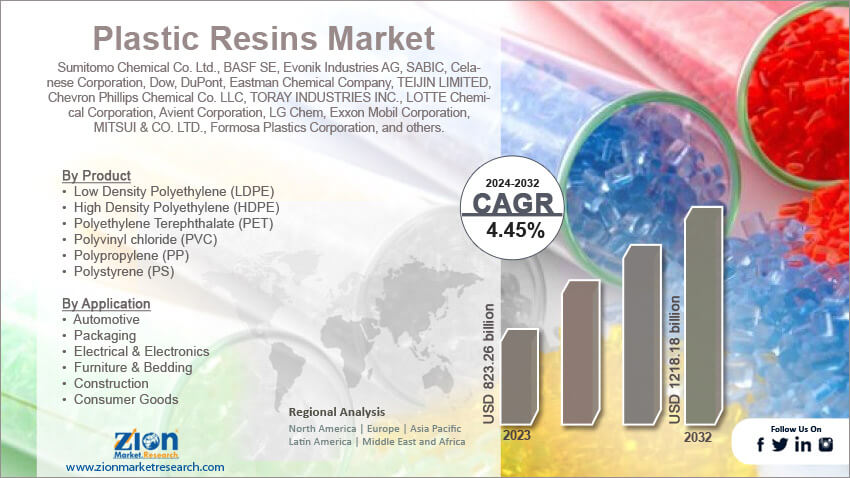

Plastic Resins Market By Product (Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polyethylene Terephthalate (PET), Polyvinyl chloride (PVC), Polypropylene (PP), Polystyrene (PS), and Others), By Application (Automotive, Packaging, Electrical & Electronics, Furniture & Bedding, Construction, Consumer Goods, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2024 - 2032

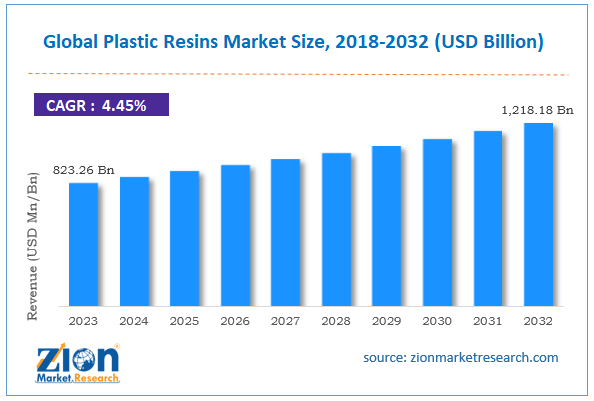

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 823.26 billion | USD 1218.18 billion | 4.45% | 2023 |

Plastic Resins Industry Prospective:

The global plastic resins market size was worth around USD 823.26 billion in 2023 and is predicted to grow to around USD 1218.18 billion by 2032 with a compound annual growth rate (CAGR) of roughly 4.45% between 2024 and 2032.

Plastic Resins Market: Overview

The process of cracking, which involves heating hydrocarbons, creates plastic resins. The system converts bigger hydrocarbon molecules, such as those from refining crude oil, into ethylene or propylene. The temperature at which the crack is employed determines how much of these two chemicals are produced. Applications for plastic resin include automotive, packaging, construction, electrical and electronic industries, and more. In the automotive sector, plastic resins are highly sought after for substructure applications as well as exterior and interior car parts. Strict laws about the recyclability and degradation of conventional materials like metal and other building materials are predicted to fuel demand for materials in pipes, windows, wires, storage tanks, and other applications in the construction industry.

Key Insights

- As per the analysis shared by our research analyst, the global plastic resins market is estimated to grow annually at a CAGR of around 4.45% over the forecast period (2024-2032).

- In terms of revenue, the global plastic resins market size was valued at around USD 823.26 billion in 2023 and is projected to reach USD 1218.18 billion by 2032.

- The increasing demand from the end-use industry is expected to drive the global plastic resins market growth over the forecast period.

- Based on the product, the Polyethylene Terephthalate (PET) segment is expected to hold the largest market share during the forecast period.

- Based on the application, the packaging segment is expected to hold a prominent market share over the projected period.

- Based on region, the Asia Pacific is expected to dominate the market during the forecast period.

Request Free Sample

Request Free Sample

Plastic Resins Market: Growth Drivers

Rising demand from the automotive industry drives market growth

When compared to more conventional materials like rubber or metal, plastics used in automobile applications can lower fuel consumption by lowering the vehicle's weight and density. Over the forecast period, rising consumer awareness of safety and health risks across various industries, including electronics, healthcare, wire & cable, construction, and automotive, is anticipated to propel the plastic products market and create a need for plastic resins. Plastics are predicted to be in high demand for exteriors, interiors, and under-hood components due to the constantly expanding automobile sector. Plastics are frequently utilized in under-the-hood vehicle components. They are also utilized in the building sector for industrial, commercial, and residential buildings that are built both inside and outside. The growing usage of plastics in the automotive industry is a result of consumer demand for safe, affordable, lightweight, and sport-utility vehicle (SUV)/MUV models with high fuel efficiency and a focus on comfort & style. In vehicle uses, plastics work better for steering wheels, handles, and interiors because of their pleasant touch and odorless nature. Therefore, this is expected to propel the plastic resins market growth during the forecast period.

Plastic Resins Market: Restraints

Fluctuations in the price of raw materials hinder market growth

Plastic resin is made from hydrocarbon fuels, which include sand, salt, coal, natural gas, and crude oil. The manufacturing of polyethylene (P.E.) in North America is dependent on natural gas, which is widely available and reasonably priced in the area. Because of this, the P.E. producers in the area compete intensely, maintaining a tight resin market and exporting substantial volumes. Future changes in supply and demand are also anticipated to maintain the volatility of plastic resin prices worldwide. The majority of raw materials are produced by petrochemical downstream processes. Seasonal changes, mismatches in supply and demand, and political unpredictability all contribute to the volatility of crude oil prices. The price of crude oil has fluctuated substantially on a global scale in the past few years. The supply of crude oil has been negatively impacted by social upheaval in key oil-producing regions including Libya, Venezuela, Nigeria, Iran, and Iraq, leading to an inelastic balance between supply and demand. These ephemeral market dynamics lead to sudden price drops and increases. However, major companies in the industry have strengthened their production capacity and forged strategic alliances to meet the growing demand for feedstock at a cheap cost globally.

Plastic Resins Market: Opportunities

Growing initiatives towards sustainability offer a lucrative opportunity for market growth

The growing initiative towards sustainability is expected to offer a lucrative opportunity for plastic resin market growth during the forecast period. For instance, in September 2023, a collaborative demonstration including the closed-loop recycling of Nylon 6 resin ("Nylon resin") recovered from End-of-Life Vehicles (ELVs) was initiated by Honda R&D Co., Ltd. (Honda) and Toray Industries, Inc. (Toray). Japan’s Ministry of Environment (MOE) certified this collaborative demonstration as a component of its initiative to create a decarbonized circular economy system. By installing and testing a prototype plant capable of processing 500 metric tons of resin annually, Honda and Toray hope to use this recycling method by the year 2027.

Plastic Resins Market: Challenges

Environmental concerns and regulations pose a major challenge to market expansion

Plastic pollution and the effects of plastic waste on the environment are serious issues. The plastic resins industry’s expansion may be constrained by stricter laws and initiatives meant to encourage recycling and reduce plastic waste. Manufacturers may incur higher operating costs as a result of complying with environmental regulations and guidelines, such as those about the usage of single-use plastics and the requirement for recycled material.

Plastic Resins Market: Segmentation

The global plastic resin industry is segmented based on product, application, and region.

Based on the product, the global plastic resins market is bifurcated into Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polyethylene Terephthalate (PET), Polyvinyl chloride (PVC), Polypropylene (PP), Polystyrene (PS), and Others. The Polyethylene Terephthalate (PET) segment is expected to hold the largest market share during the forecast period. PET belongs to the polyester family and is a thermoplastic polymer resin. The manufacturing of textiles for clothes, food & drink containers, and thermoforming applications are among its frequent uses. PET is perfect for beverage packaging because of its lightweight, transparency, and recyclable nature. Global demand for soft drinks, bottled water, and other beverages is driven by their rising usage.

Based on the application, the global plastic resins industry is bifurcated into automotive, packaging, electrical & electronics, furniture & bedding, construction, consumer goods, and others. The packaging segment is expected to hold a prominent market share over the projected period. Category expansion will be driven by the growing packaging industry, which is being bolstered by the growing demand for packaged goods and drinks. In addition, several governmental organizations have set strict guidelines on the safe application of plastic materials in food and beverage applications, which is anticipated to encourage market growth.

Plastic Resins Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Plastic Resins Market |

| Market Size in 2023 | USD 823.26 Billion |

| Market Forecast in 2032 | USD 1,218.18 Billion |

| Growth Rate | CAGR of 4.45% |

| Number of Pages | 207 |

| Key Companies Covered | Sumitomo Chemical Co. Ltd., BASF SE, Evonik Industries AG, SABIC, Celanese Corporation, Dow, DuPont, Eastman Chemical Company, TEIJIN LIMITED, Chevron Phillips Chemical Co. LLC, TORAY INDUSTRIES INC., LOTTE Chemical Corporation, Avient Corporation, LG Chem, Exxon Mobil Corporation, MITSUI & CO. LTD., Formosa Plastics Corporation, and others. |

| Segments Covered | By Product, By Application, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Plastic Resins Market: Regional Analysis

Asia Pacific is estimated to hold the largest revenue share over the projected period

The Asia Pacific is estimated to hold the largest revenue share in 2023 and is anticipated to hold the dominant position in the plastic resin market over the coming years. This is a result of factors like the region's rapid urbanization, increased building activity, and growing demand for consumer goods and packaging. China is a major manufacturing nation that contributes to the increased need for plastic resins in industries including electronics, construction, automotive, and packaging. Moreover, a significant factor propelling the market's expansion is the need for polyethylene terephthalate (PET) plastic bottles for the packaging of bottled water, juices, soft drinks, pills, household cleansers, and personal care products.

Plastic Resins Market: Competitive Analysis

The global plastic resins market is dominated by players like:

- Sumitomo Chemical Co. Ltd.

- BASF SE

- Evonik Industries AG

- SABIC

- Celanese Corporation

- Dow

- DuPont

- Eastman Chemical Company

- TEIJIN LIMITED

- Chevron Phillips Chemical Co. LLC

- TORAY INDUSTRIES INC.

- LOTTE Chemical Corporation

- Avient Corporation

- LG Chem

- Exxon Mobil Corporation

- MITSUI & CO. LTD.

- Formosa Plastics Corporation

- And Others

The global plastic resins market is segmented as follows:

By Product

- Low Density Polyethylene (LDPE)

- High Density Polyethylene (HDPE)

- Polyethylene Terephthalate (PET)

- Polyvinyl chloride (PVC)

- Polypropylene (PP)

- Polystyrene (PS)

- Others

By Application

- Automotive

- Packaging

- Electrical & Electronics

- Furniture & Bedding

- Construction

- Consumer Goods

- Others

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The process of cracking, which involves heating hydrocarbons, creates plastic resins. The system converts bigger hydrocarbon molecules, such as those from refining crude oil, into ethylene or propylene. The temperature at which the crack is employed determines how much of these two chemicals are produced. Applications for plastic resin include automotive, packaging, construction, electrical and electronic industries, and more. In the automotive sector, plastic resins are highly sought after for substructure applications as well as exterior and interior car parts.

Strict laws about the recyclability and degradation of conventional materials like metal and other building materials are predicted to fuel demand for materials in pipes, windows, wires, storage tanks, and other applications in the construction industry, thereby driving the plastic resins market growth.

According to the report, the global plastic resins market size was worth around USD 823.26 billion in 2023 and is predicted to grow to around USD 1218.18 billion Billion by 2032.

The global plastic resin market is expected to grow at a CAGR of 4.45% during the forecast period.

The global plastic resin market growth is expected to be driven by the Asia Pacific. It is currently the world’s highest revenue-generating market due to the growing automotive industry.

The global plastic resins market is dominated by players like Sumitomo Chemical Co., Ltd., BASF SE, Evonik Industries AG, SABIC, Celanese Corporation, Dow, DuPont, Eastman Chemical Company, TEIJIN LIMITED, Chevron Phillips Chemical Co., LLC, TORAY INDUSTRIES, INC., LOTTE Chemical Corporation, Avient Corporation, LG Chem, Exxon Mobil Corporation, MITSUI & CO. LTD and Formosa Plastics Corporation among others.

The plastic resins market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTLE analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five forces analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed