Powder Metallurgy Components Market Size, Share, Trends, Growth 2032

Powder Metallurgy Components Market By Product (Ferrous Metals and Non-Ferrous Metals) and By Application (Automotive, Aerospace, Medical, Industrial, Electrical & Electronics, and Others), And By Region - Global And Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, And Forecasts 2024 - 2032

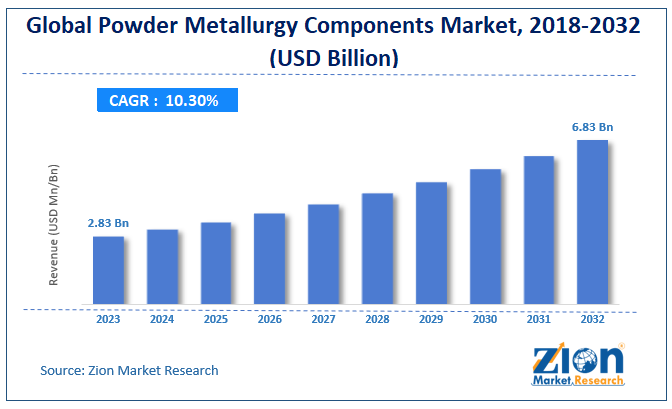

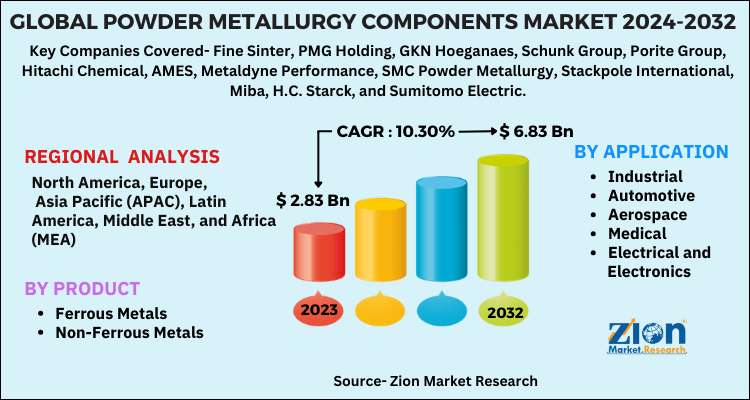

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 2.83 Billion | USD 6.83 Billion | 10.30% | 2023 |

Powder Metallurgy Components Industry Prospective:

The global powder metallurgy components market size was evaluated at $2.83 billion in 2023 and is slated to hit $6.83 billion by the end of 2032 with a CAGR of nearly 10.30% between 2024 and 2032.

The study covers the key drivers and restraints of the powder metallurgy components market and provides the market impact within the forecast period. Furthermore, the study also includes the opportunities accessible within the powder metallurgy components market on a global level.

Powder Metallurgy Components Market: Growth Factors

Powder metallurgy is a term that covers a broad variety of aspects where different components or parts are produced from various metal powders. Powder metallurgy is a cost-effective method that is used to create net-shaped, precise steel parts. Powder metallurgy components have been increasingly used across various industry applications, such as automotive, aerospace, and industrial applications.

The global powder metallurgy components market is projected to grow at the highest rate in the next few years, owing to the flourishing automotive industry across the globe. The rising demand for electric vehicles is further expected to enhance the applications of powder metallurgy components, thus fuelling the powder metallurgy components market globally. Additionally, the surging demand for electronic products is likely to enhance the consumption of titanium and aluminum-based components, thereby, propelling the powder metallurgy components market.

However, high capital investment for powder metallurgy processing equipment may hinder this global market’s growth in the future. Alternatively, advancements in different manufacturing technologies of powder metallurgy components are expected to offer new growth opportunities to the powder metallurgy components market.

In order to offer the users of this report, a comprehensive view of the powder metallurgy components market, we have enclosed a detailed value chain analysis. To know the competitive landscape within the market, an analysis of Porter’s Five Forces model for the powder metallurgy components market has additionally been enclosed within the study. The study includes a market attractiveness analysis, wherein all the segments are benchmarked supported their market size, growth rate, and general attractiveness.

The study also includes the market share of the key participant’s operating in the powder metallurgy components market across the globe. Additionally, the report covers the strategic development together with acquisitions & mergers, agreements, partnerships, collaborations, and joint ventures, and regional growth of key players within the market on a regional basis.

Powder Metallurgy Components Market: Segmentation

The powder metallurgy components market is divided based on product and application.

Based on product, the powder metallurgy components market is classified into ferrous metals (steel and iron) and non-ferrous metals (tungsten, copper, aluminum, and others). Ferrous metals contributed the maximum share to the global market in 2018 and are expected to maintain their dominance in the upcoming years as well. By application, the market includes electrical and electronics, automotive, medical, aerospace, industrial, and others.

The automotive segment contributed the largest share to the powder metallurgy components market globally in 2018. The constantly developing automotive industry across the globe is estimated to further boost the applications of powder metallurgy components in the automotive sector. The industrial segment is expected to grow at a fast rate in the years ahead.

Powder Metallurgy Components Market : Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Powder Metallurgy Components Market Research Report |

| Market Size in 2023 | USD 2.83 Billion |

| Market Forecast in 2032 | USD 6.83 Billion |

| Growth Rate | CAGR of 10.30% |

| Number of Pages | 215 |

| Key Companies Covered | Fine Sinter, PMG Holding, GKN Hoeganaes, Schunk Group, Porite Group, Hitachi Chemical, AMES, Metaldyne Performance, SMC Powder Metallurgy, Stackpole International, Miba, H.C. Starck, and Sumitomo Electric |

| Segments Covered | By Product, By Application and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Powder Metallurgy Components Market: Regional Insights

The regional classification includes Europe, North America, Latin America, Asia Pacific, and the Middle East and Africa.

The North American powder metallurgy components market dominated globally in 2018, due to the region’s growing automotive industry. The Asia Pacific powder metallurgy components market is projected to show the highest CAGR over the projected time period, owing to the growing demand for powder metallurgy for a wide range of industrial applications, to produce power tools and components.

Powder Metallurgy Components Market: Competitive Space

The global powder metallurgy components market profiles key players such as

- Fine Sinter

- PMG Holding

- GKN Hoeganaes

- Schunk Group

- Porite Group

- Hitachi Chemical

- AMES

- Metaldyne Performance

- SMC Powder Metallurgy

- Stackpole International

- Miba

- H.C. Starck

- Sumitomo Electric

This report segments the global powder metallurgy components market into:

Global Powder Metallurgy Components Market: Product Analysis

- Ferrous Metals

- Iron

- Steel

- Non-Ferrous Metals

- Aluminum

- Copper

- Tungsten

- Others

Global Powder Metallurgy Components Market: Application Analysis

- Industrial

- Automotive

- Aerospace

- Medical

- Electrical and Electronics

- Others

Global Powder Metallurgy Components Market: Regional Analysis

- North America

- The U.S.

- Europe

- UK

- France

- Germany

- Asia Pacific

- China

- Japan

- India

- Latin America

- Brazil

- Middle East and Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Components manufactured via powder metallurgy (PM) are those that result from the fabrication process. Powder metallurgy entails the compacting of metal granules into the intended form, followed by sintering to solidify them into functioning pieces.

Among the greatest consumers of PM components, the automotive sector employs them to manufacture gears, bearings, engine parts, and transmission components. The automotive sector's ongoing expansion, specifically the emergence of electric vehicles, could potentially lead to a corresponding surge in the need for PM components.

The global powder metallurgy components market size was evaluated at $2.83 billion in 2023 and is slated to hit $6.83 billion by the end of 2032.

The global powder metallurgy components market a CAGR of nearly 10.30% between 2024 and 2032.

The regional classification includes Europe, North America, Latin America, Asia Pacific, and the Middle East and Africa.

Some key players of the global powder metallurgy components market are Fine Sinter, PMG Holding, GKN Hoeganaes, Schunk Group, Porite Group, Hitachi Chemical, AMES, Metaldyne Performance, SMC Powder Metallurgy, Stackpole International, Miba, H.C. Starck, and Sumitomo Electric.

RelatedNews

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed