PTFE Hoses Market Trend, Share, Growth, Size and Analysis 2030

PTFE Hoses Market By Braid Type (Stainless Steel, Monel, Bronze, Polypropylene, Polyvinylidene Fluoride (PVDF), Other Braid Types), By Inner Core Shape (Smooth And Convoluted), By Type (Conductive And Nonconductive), By End-user Industry (Automotive & Heavy Machinery, Aerospace, Petrochemical, Paints & Coatings, Food & Beverage, Pharmaceutical, Bulk Chemical, Other End-user Industries), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, And Forecasts 2023 - 2030

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 660 Million | USD 968 Million | 4.90% | 2022 |

PTFE Hoses Industry Perspective:

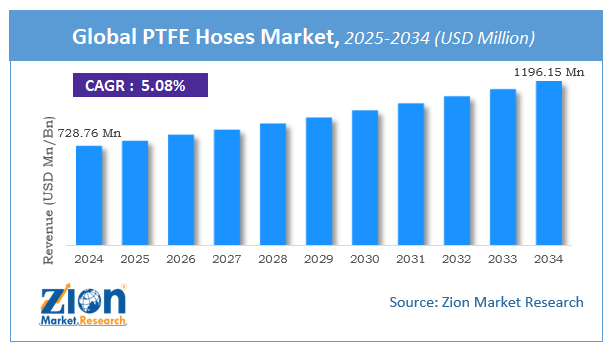

The global PTFE hoses market size was worth around USD 660 million in 2022 and is predicted to grow to around USD 968 million by 2030 with a compound annual growth rate (CAGR) of roughly 4.90% between 2023 and 2030.

The report analyzes the global PTFE hoses market’s drivers, restraints/challenges, and the effect they have on the demands during the projection period. In addition, the report explores emerging opportunities in the PTFE hoses industry.

PTFE Hoses Market: Overview

PTFE hose comprises a smooth or convoluted polytetrafluoroethylene (PTFE) tube liner and single or double outer braid, generally based on stainless steel, polypropylene, bronze, etc. PTFE is a synthetic fluoropolymer of tetrafluoroethylene. PTFE hoses offer good temperature characteristics both in high and low temperatures, non-contamination characteristics, good chemical resistance, low coefficient of friction, high flexibility, good kink resistant, and good resistance to deterioration. These hoses are suitable for various high-pressure applications.

PTFE is inert to most commercial chemicals and generally, no adhesives are used in the construction of these PTFE hoses, hence, there is no chance of contamination. PTFE hose provides low friction to the fluid, which diminishes pressure drops and avoids unwanted deposits buildups. The use of a conductive inner tube is not necessary for the majority of PTFE hose applications. Sometimes, during PTFE hose manufacturing, carbon is added to the PTFE inner tube wall, such that to direct the accumulated electrostatic charge to the inner diameter of the hose to the metal end fittings. This is done to offset the potential hazard of electrostatic discharge.

Considering these favorable characteristics, these hoses are used in various end-user industries such as automotive, aerospace, chemical, food & beverage, pharmaceutical, and plastic & rubber molding machines, among others. Some of the widely used PTFE hoses are chemical hoses, food hoses, composite hoses, high-pressure gas hoses, ducting hoses, and brake hoses. In various applications, PTFE has been shown to outperform other alternatives such as silicone, rubber, silicone, polyvinyl chloride (PVC), and others. Most of the manufacturers use PTFE, which complies with Annex I of (EU) 2019/ 1021 and (EU) 2017/1000 amending to Annex XVII of EU REACH regulations related to perfluorooctanoic acid (PFOA) and its related substances.

Key Insights

- As per the analysis shared by our research analyst, the global PTFE hoses market is estimated to grow annually at a CAGR of around 4.90% over the forecast period (2023-2030).

- In terms of revenue, the global PTFE hoses market size was valued at around USD 660 million in 2022 and is projected to reach USD 968 million, by 2030.

- The global PTFE hoses market is projected to grow at a significant rate due to the increasing demand from the automotive industry, across the globe.

- Based on braid type segmentation, stainless steel was predicted to show maximum market share in the year 2022.

- Based on inner core shape segmentation, smooth was the leading revenue generator in 2022.

- Based on type segmentation, nonconductive was predicted to show maximum market share in 2022.

- Based on end-user industry segmentation, automotive & heavy machinery was the leading revenue-generating end-user industry in 2022.

- On the basis of region, Asia Pacific was the leading revenue generator in 2022.

Request Free Sample

Request Free Sample

PTFE Hoses Market: Growth Drivers

Increasing demand from the automotive industry to drive market growth during the forecast period.

The global PTFE hoses market is projected to grow owing to the increasing applications of PTFE hoses in automobile applications. Considering its characteristics such as high pressure and temperature resistance, low friction, and chemical inertness, PTFE hoses are widely used in the vehicle industry. These PTFE hoses are used for applications such as brake lines, fuel lines, coolant hoses, and vacuum lines, among others. The automotive sector uses both conductive and nonconductive PTFE hoses. PTFE hoses with conductive liners are usually made of carbon black, which offers conductivity throughout the length of the PTFE hose for static charge dissipation, to avoid potential hazards.

These static charges can be dangerous, if not dissipated properly, in certain applications, where any minimal spark can ignite the fuel. Considering these factors, conductive PTFE hoses are suitable for fuel lines, running gas lines, ethanol fuel such as E85 lines, methanol lines, and others. Whereas, nonconductive PTFE hoses do not comprise any conductive liner. Nonconductive hoses offer more safety to some fluids, which may get contaminated due to the presence of conductive materials in PTFE. Nonconductive PTFE hoses also have a lower coefficient of friction than conductive PTFE hoses, which makes them suitable for use in high-pressure applications. Some of the key applications for nonconductive PTFE hoses in automobiles are such as clutch lines, brake lines, hydraulic lines, and vacuum lines.

In March 2022, Kongsberg Automotive signed a contract worth EUR 58 million in estimated lifetime revenue with a global automotive Tier 1 supplier based in North America for the supply of its Fluoro-Comp hose (non-metallic reinforced PTFE hose) and stainless-steel braided PTFE brake lines.

In January 2023, Unigasket S.r.l. acquired MTO Hose Solution Inc, which is a provider of PTFE hoses for automotive and other sector applications. Unigasket S.r.l. is also a provider of PTFE hoses for the passage of oil for various automobile applications.

For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), in 2022, around 85,016,728 units of vehicles were produced, across the globe, witnessing a growth rate of around 6% compared to the previous year. The rising production trends in the automotive sector are supporting the demand for the PTFE hoses industry.

PTFE Hoses Market: Restraints

Availability of substitutes to restrict market expansion

The global hoses industry has a wide range of alternatives for PTFE hoses. Some of the key substitutes for PTFE hoses are nitrile, chlorinated polyethylene (CPE), nylon, polyester, polychloroprene, as well as some other fluoropolymers, such as fluorinated ethylene-propylene (FEP), per-fluoro-alkoxy (PFA), modified fluoro-alkoxy (MFA), ethylene tetrafluoroethylene (ETFE), and ethylene chlorotrifluoroethylene (ECTFE), among others. These hoses can be used in respective end-user sectors such as automotive, aerospace, chemical, and others. Ethylene tetrafluoroethylene (ETFE) and ethylene chlorotrifluoroethylene (ECTFE) hoses can act as a close substitute for PTFE hoses. Rubber hoses can act as low-cost alternatives for PTFE hoses in low-end applications. Thus, the availability and uses of these alternatives are expected to hinder the PTFE hoses industry’s growth, in the coming years.

PTFE Hoses Market: Opportunities

Increasing development of PTFE hoses for the biopharmaceutical industry to provide growth opportunities

Various manufacturers are developing PTFE hoses for the fast-growing biopharmaceutical industry, owing to their various characteristics such as good resistance to most of the chemicals, and others. Biopharmaceuticals manufacturing is based on living organisms using biological processes. Biopharmaceutical manufacturing plants require specific standards and norms for hoses such as EN 12115 standards. Moreover, its cleanability and steam resistance characteristics are in line with a biopharmaceutical hygienic environment. Some of the key applications of PTFE hose in the biopharmaceutical sector are water for injection (WFI)/ hot water for injection (HWFI), load cell, reagents, steam, process liquids, and delivery systems, among others. According to the Pharmaceutical Research and Manufacturers of America, the biopharmaceutical industry in the U.S. is the leading research and development (R&D) and advanced manufacturing industry. The U.S. biopharmaceutical export value accounted for around USD 83 billion in 2021 and has increased significantly in 2022.

Furthermore, as per the European Federation of Pharmaceutical Industries and Associations, the number of new chemical and biological entities developed during 2018-2022 accounted for 364 units, compared to 246 units in the previous four-year time period. These product developments are likely to enhance in the coming years. Rising investment in setting up biopharmaceutical manufacturing plants is likely to support the demand for PTFE hoses industry in the coming years.

PTFE Hoses Market: Challenges

High cost of adoption to challenge market cap growth

PTFE hoses are, generally, more expensive compared to other hose types such as rubber hoses and polyvinyl chloride hoses, among others. PTFE material is the key cost factor for PTFE hoses. Additionally, the techniques involved in processing the PTFE inner core are expensive and proprietary. Specifically, although conductive PTFE hose assemblies have several benefits, their high cost prevents them from being used in a wider range of applications. However, the challenge from the cost factor can be mitigated, considering PTFE hose favorable properties offering high-end demanding applications.

PTFE Hoses Market: Segmentation

The global PTFE hoses market is segmented based on braid type, inner core shape, type, end-user industry, and region.

Based on braid type, the global market segments are stainless steel, Monel, bronze, polypropylene, polyvinylidene fluoride (PVDF), and other braid types. Currently, the global market is dominated by stainless steel, considering its high suitability in a wide range of applications. Some of the key stainless-steel grades used in braiding PTFE inner cores are 304 stainless steel and 316 stainless steel, among others. Stainless steel braided PTFE hoses are general-purpose products and can be used in applications involving high temperature and operating pressure. Outside braiding is done to provide pressure resistance and external protection to the hose assembly. PARKER HANNIFIN CORP, Saint-Gobain, and Gates Corporation are among the key manufacturers of stainless-steel braided PTFE hoses for a wide range of applications.

Based on the inner core shape, the PTFE hoses industry is segmented into smooth and convoluted. The smooth segment dominated the market share in 2022. Smooth PTFE hose comprises a smooth & straight PTFE tube liner and an outer braid. A smooth inner surface offers low friction and good flow characteristics. Smooth PTFE hoses are used for many applications such as pharmaceuticals, high-pressure gas, biopharmaceutical, food processing, chemical transfer, industrial process water, etc.

Based on the type, the PTFE hoses industry is segmented into conductive and non-conductive. The non-conductive segment dominated the market share in 2022. Nonconductive PTFE hoses do not comprise any conductive liner. The application of a conductive inner tube is not necessary for different end-use sectors. Nonconductive hoses offer more safety to some fluids, which may get contaminated due to the presence of conductive materials, such as carbon black and others, in PTFE. These PTFE hoses are suitable for use in high-pressure applications.

Based on the end-user industry, the global market segments are automotive & heavy machinery, aerospace, petrochemical, paints & coatings, food & beverage, pharmaceutical, bulk chemical, and other end-user industries. Currently, the PTFE hoses industry is dominated by the automotive & heavy machinery segment. For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), in 2022, around 81,628,533 units of vehicles were sold, across the globe, witnessing a decline rate of around 1.4% compared to the previous year.

In May 2023, the Indian government asked heavy equipment manufacturers to manufacture heavy machinery within India, which is likely to reduce the country’s import worth around INR 3,500 crore. Furthermore, Volvo Construction Equipment (Volvo CE) has achieved a steady rise in 2022. In the full year 2022, Volvo Construction Equipment achieved net sales of around SEK 100,261 million, registering a growth rate of around 8.94% compared to the previous year. Such factors are likely to support the demand for PTFE hoses used in heavy machinery.

PTFE Hoses Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | PTFE Hoses Market Report |

| Market Size in 2022 | USD 660 Million |

| Market Forecast in 2030 | USD 968 Million |

| Growth Rate | CAGR of 4.90% |

| Number of Pages | 233 |

| Key Companies Covered | Crane ChemPharma & Energy, Eaton, Flexotech, Gates Corporation, Graco Inc., HANSA-FLEX AG, Kongsberg Automotive, KURIYAMA OF AMERICA INC. (ALFA GOMMA Spa), Kurt Manufacturing, Metline Industries, PARKER HANNIFIN CORP, Polyhose, PTFEFLEX, Saint-Gobain, Sanipure Water Systems, Swagelok Company, Titeflex, Transfer Oil S.p.A., Unigasket S.r.l., Watson-Marlow Fluid Technology Solutions (Aflex Hose), and Xtraflex BV. |

| Segments Covered | By Braid Type, By Inner Core Shape, By Type, By End-user Industry, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

PTFE Hoses Market: Regional Analysis

Asia Pacific to lead the market during the forecast period

The global PTFE hoses market growth is expected to be driven by Asia Pacific, during the forecast period. Various end-user industries such as automotive, aerospace, pharmaceutical, paints and coatings, and petrochemical, among others, are the key consumers of PTFE hoses in different fluid applications.

According to the Global Market Forecast (GMF) released by AIRBUS, around 9,480 new passenger & freighter aircraft deliveries are expected to be made during 2023-2042 in Asia Pacific (excluding China), out of which 79% units are likely to be a single aisle, and 21% units are expected to be widebody. Specifically, in China, around 9,440 new passenger & freighter aircraft deliveries are expected to be made during 2023-2042.

Furthermore, Asia Pacific is significantly engaged in the production of automobiles, accounting for around 58.8% of total global production in 2022. For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), in 2022, around 5,00,20,793 units of vehicles were produced in Asia Pacific, witnessing a growth rate of around 7% compared to the previous year. All such factors support the growth of the PTFE hoses industry.

The pharmaceutical industry is another key consumer of PTFE hoses. According to the India Brand Equity Foundation (IBEF), over 50% of the global demand for various vaccines is met by the Indian pharmaceutical industry, along with 25% of all pharmaceuticals in the United Kingdom and around 40% of the demand for generics in the U.S. is being fulfilled by the Indian pharmaceutical sector. Moreover, in May 2022, Dr. Reddy's Laboratories and HK inno.N Corp. announced to work together to commercialize the new compound Tegoprazan in India and a few other emerging markets. Such development is expected to propel the demand for PTFE hoses from both the current R&D and upcoming manufacturing phases in India.

PTFE Hoses Market: Competitive Analysis

The global PTFE hoses market is dominated by players like:

- Crane ChemPharma & Energy

- Eaton

- Flexotech

- Gates Corporation

- Graco Inc.

- HANSA-FLEX AG

- Kongsberg Automotive

- KURIYAMA OF AMERICA, INC. (ALFA GOMMA Spa)

- Kurt Manufacturing

- Metline Industries

- PARKER HANNIFIN CORP

- Polyhose

- PTFEFLEX

- Saint-Gobain

- Sanipure Water Systems

- Swagelok Company

- Titeflex

- Transfer Oil S.p.A.

- Unigasket S.r.l.

- Watson-Marlow Fluid Technology Solutions (Aflex Hose)

- Xtraflex BV

The global PTFE hoses market is segmented as follows:

By Braid Type

- Stainless Steel

- Monel

- Bronze

- Polypropylene

- Polyvinylidene Fluoride (PVDF)

- Other Braid Types

By Inner Core Shape

- Smooth

- Convoluted

By Type

- Conductive

- Nonconductive

By End-user Industry

- Automotive & Heavy Machinery

- Aerospace

- Petrochemical

- Paints & Coatings

- Food & Beverage

- Pharmaceutical

- Bulk Chemical

- Other End-user Industries

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

PTFE hose comprises a smooth or convoluted polytetrafluoroethylene (PTFE) tube liner and single or double outer braid, generally based on stainless steel, polypropylene, bronze, etc. PTFE is a synthetic fluoropolymer of tetrafluoroethylene.

The global PTFE hoses market cap may grow owing to the rising demand from the automotive industry, across the globe. Significant growth opportunities can be expected due to the development & increasing usage of PTFE hoses in biopharmaceutical sectors.

According to study, the global PTFE hoses market size was worth around USD 660 million in 2022 and is predicted to grow to around USD 968 million by 2030.

The CAGR value of the PTFE hoses market is expected to be around 4.90% during 2023-2030.

The global PTFE hoses market growth is expected to be driven by Asia Pacific. It is currently the world’s highest revenue-generating market owing to the presence of a huge footprint of end-user industries such as aerospace, automotive & heavy machinery, petrochemical, and others.

The global PTFE hoses market is led by players like Crane ChemPharma & Energy, Eaton, Flexotech, Gates Corporation, Graco Inc., HANSA-FLEX AG, Kongsberg Automotive, KURIYAMA OF AMERICA, INC. (ALFA GOMMA Spa), Kurt Manufacturing, Metline Industries, PARKER HANNIFIN CORP, Polyhose, PTFEFLEX, Saint-Gobain, Sanipure Water Systems, Swagelok Company, Titeflex, Transfer Oil S.p.A., Unigasket S.r.l., Watson-Marlow Fluid Technology Solutions (Aflex Hose), and Xtraflex BV.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed