Roller Benders Market Size Report, Industry Share, Analysis, Growth, 2030

Roller Benders Market By Application (Transportation, Construction & Building, Oil & Gas, Energy Industry, Home Appliances, and Others), By Type (Two-Roller, Three-Roller, and Four-Roller), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

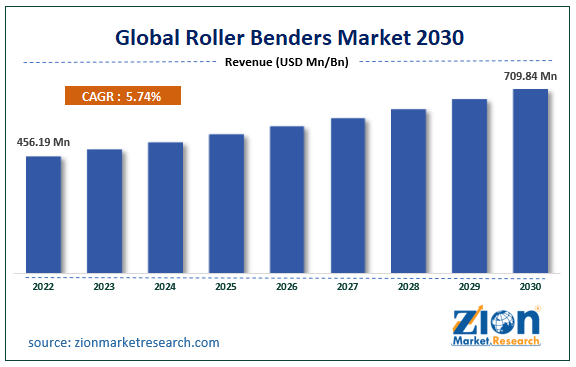

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

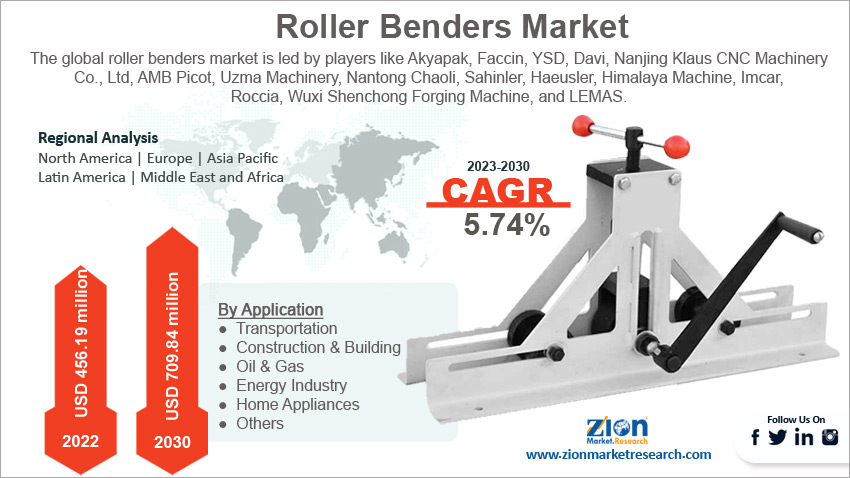

| USD 456.19 Million | USD 709.84 Million | 5.74% | 2022 |

Roller Benders Industry Prospective:

The global roller benders market size was worth around USD 456.19 million in 2022 and is predicted to grow to around USD 709.84 million by 2030 with a compound annual growth rate (CAGR) of roughly 5.74% between 2023 and 2030.

The report delves deeper into several crucial aspects of the global roller benders industry. It includes a detailed discussion of existing growth factors and restraints. Future growth opportunities and challenges that impact the roller benders market are comprehensively addressed in the report.

Roller Benders Market: Overview

A roller bender is a mechanical jig or device used for converting a metal rod or bars into a circular arc. It consists of three rollers that rotate freely around three parallel axes. These rollers are placed at uniform horizontal spacing between them thus creating a coherent structure.

The structure of a three-roller bender consists of two rollers placed at the bottom and assisting in cradling the metal rod while the third roller is placed at the top forming a triangular shape with the other two rods and helps in pressing the top part of the material.

The roller at the top is adjustable and allows flexibility to the unit. During the process of converting a metal rod into a circular arc, the object is first inserted in the jig and the roller at the top of the triangle is manually lowered. This mechanism creates a force on the rod or the bar with the help of a screw arrangement causing it to undergo plastic and elastic deformation. The other more common roller benders are two-roller and three-roller counterparts.

Key Insights:

- As per the analysis shared by our research analyst, the global roller benders market is estimated to grow annually at a CAGR of around 5.74% over the forecast period (2023-2030)

- In terms of revenue, the global roller benders market size was valued at around USD 456.19 million in 2022 and is predicted to grow to around USD 709.84 million, by 2030.

- The roller benders market is projected to grow at a significant rate due to the growing demand for sustainable packaging

- Based on application segmentation, construction & building was predicted to show maximum market share in the year 2022

- Based on type segmentation, four-roller was the leading type in 2022

- On the basis of region, Asia-Pacific was the leading revenue generator in 2022

Request Free Sample

Request Free Sample

Roller Benders Market: Growth Drivers

Increasing application in the construction industry to drive market growth

The global roller bender market is projected to grow owing to the rising application of roller benders in the expansion construction sector. These industrial equipments are highly versatile as they can be used to achieve complex and simple metal-based structural parts which are currently the prime necessity in the construction & building sector. Metals are used extensively across construction sites including education facilities, hospitals, coastal defenses, skyscrapers, and commercial buildings along with other forms of modern architecture.

Roller benders help mold strong metal objects including steel in desired shape. In May 2023, the Kiran Nadar Museum of Art in India announced its plan to expand its contribution to promoting the Indian art form. The private institute unveiled a plan for a new building project which will be spread across 100,000 sq mt. It will be located on Delhi National Highway. In June 2022.

Similarly in June 2022, Zaha Hadid Architects (ZHA) was awarded an opportunity to design a new building in the Shaanxi province of China. The institute will contribute to designing the new Culture & Art Centre. Emerging economies are working toward building an attractive and state-of-the-art infrastructure to compete with their Western counterparts as a means to improve foreign investment, international tourism, and higher domestic economic growth.

Rising investments in the oil & gas sector to fuel market expansion

Roller benders have applications in the production of several components used during drilling, exploration, and refining processes in the oil & gas sector. The rising investments in the oil industry due to growing demand from end-consumers could help create higher growth opportunities for roller benders. In June 2023, Saudi Aramco, a leading player in the oil industry, announced that it had awarded steel pipe manufacturing and supplying contracts to two Saudi-listed companies. The total project is worth USD 55 million while the companies involved in the production are Group Five Pipe Saudi Company and East Pipes Integrated Company.

Roller Benders Market: Restraints

Excessive dependence on manual labors to restrict market expansion

The use of roller benders is an extremely time-consuming process since it depends heavily on input from humans. The process has excessive dependence on human labor as each bar has to be manually processed. In addition to this, there are added difficulties in obtaining the desired result since the top roll of the machine has to be adjusted repeatedly which requires considerable human force.

In such conditions, it can be difficult to obtain high accuracy, especially during the manufacturing of complex parts or structures. Further, the process of bending metals using roller benders is highly technical and can be handled only under the guidance of skilled personnel and certain economies are witnessing mass departure of workforce to other countries for better job opportunities.

Roller Benders Market: Opportunities

Rising application in the energy and power generation sector to provide growth opportunities

Roller benders are used to produce metal-based parts used in electric grid installations, power plants, and other energy-producing or distributing structures. The growing investments in the generation and application and use of renewable energy are expected to provide higher growth opportunities for the players operating in the roller benders industry.

A February 2023 report by the U.S Energy Information Administration suggested that the country intends to fulfill half of its electricity demand using solar panels. In addition to this, as of April 2023, the government of India has announced that it will be issuing tenders for a new renewable capacity of 250 GW by 2028.

By 2030, the country plans to improve its non-fossil-based energy capacity by 50% of the current value.

Rising partnerships in the industry to generate further growth avenues

The manufacturers of roller benders are investing in developing strategic partnerships with other players to meet the changing trends in the commercial world and rising consumer expectations. As the rate of innovation in the production of advanced roller benders continues to grow, more avenues for further progress can be expected.

In March 2023, MG srl, an Italy-based manufacturer of roller benders sold a new model called the ME 3095 N to CuBuilt Engineers Pvt Ltd. It is a four-roll plate machine with a 70-mm standard pre-bending capacity and 95-mm standard rolling capacity.

Roller Benders Market: Challenges

Large space requirements to install roller benders create challenges for market expansion

Advanced roller benders typically have large space requirements for installation. This could create challenges for companies with limited space availability. This is especially applicable to machines that have higher functionalities. In addition to this, the cost of roller benders increases with the addition of new features leading to cost-related constraints along with expenses associated with the maintenance of the mechanical device. Since the devices work with manual assistance, there is a risk of accidents caused by machine error or negligent handling of the system. Issues such as the use of excess loading over the maximum capacity limit, material ejection, and default in the system could lead to loss of life and other resources.

Roller Benders Market: Segmentation

The global roller benders market is segmented based on application, type, and region.

Based on application, the global market segments are transportation, construction & building, oil & gas, energy industry, home appliances, and others. The most dominating segment was the construction & building industry led by growing demand for aesthetically pleasing and advanced building architecture including all forms of structural frameworks such as staircases, railing, and other components.

The steady lifestyle change driven by growing product innovation and improving disposable income rate has assisted in higher growth in the commercial building sub-segment of the larger construction industry. Moreover, surging investments in non-commercial structures such as hospitals and educational units also assist in generating a significant portion of the revenue.

The global construction & building industry is expected to grow at a CAGR of more than 6% by 2028.

Based on type, the roller benders industry is divided into two-roller, three-roller, and four-roller. The market is currently led by the four-roller segment due to product versatility along with high precision. 4-roller benders offer higher accuracy due to the installation of advanced technology and are considered best suited for high production runs.

Time taken by these variants is considerably less when compared to other forms and the performance output is further increased with the installation of computer numerical control. Two-roller machines can perform well with materials that are less than 24 inches wide.

Roller Benders Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Roller Benders Market Research Report |

| Market Size in 2022 | USD 456.19 Million |

| Market Forecast in 2030 | USD 709.84 Million |

| Growth Rate | CAGR of 5.74% |

| Number of Pages | 217 |

| Key Companies Covered | Akyapak, Faccin, YSD, Davi, Nanjing Klaus CNC Machinery Co. Ltd, AMB Picot, Uzma Machinery, Nantong Chaoli, Sahinler, Haeusler, Himalaya Machine, Imcar, Roccia, Wuxi Shenchong Forging Machine, and LEMAS. |

| Segments Covered | By Application, By Type, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Roller Benders Market: Regional Analysis

Asia-Pacific to witness the highest growth during the projection period

The global roller benders market is expected to witness the highest growth in Asia-Pacific with China leading the regional revenue. The country’s construction industry is booming and in 2021, it contributed nearly USD 1.49 trillion to China’s gross domestic product (GDP). The growing rate of domestic investment, increasing foreign trade, and development of excellent strategic partnerships with other Asian countries are triggering a high influx of revenue in China’s construction sector.

In addition to this, India can contribute to the regional roller-bender market as the country continues to increase its hold in the oil & gas sector. In January 2023, it was reported that India will witness an investment of USD 48 billion in the oil & gas sector.

The presence of key manufacturers of roller blenders in Asian regions further act as crucial contributors to regional revenue. These companies are extending partnerships with international players which opens doors for higher growth opportunities. Europe may also grow at a steady CAGR with extensive application or roller benders in the regional end-user verticals. Europe also has key manufacturers and suppliers of advanced roller blenders which helps the economy grow.

Roller Benders Market: Competitive Analysis

The global roller benders market is led by players like:

- Akyapak

- Faccin

- YSD

- Davi

- Nanjing Klaus CNC Machinery Co. Ltd

- AMB Picot

- Uzma Machinery

- Nantong Chaoli

- Sahinler

- Haeusler

- Himalaya Machine

- Imcar

- Roccia

- Wuxi Shenchong Forging Machine

- LEMAS

The global roller benders market is segmented as follows:

By Application

- Transportation

- Construction & Building

- Oil & Gas

- Energy Industry

- Home Appliances

- Others

By Type

- Two-Roller

- Three-Roller

- Four-Roller

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

A roller bender is a mechanical jig or device used for converting a metal rod or bars into a circular arc

The global roller bender market is projected to grow owing to the rising application of roller benders in the expansion construction sector.

According to study, the global roller benders market size was worth around USD 456.19 million in 2022 and is predicted to grow to around USD 709.84 million by 2030.

The CAGR value of the roller benders market is expected to be around 5.74% during 2023-2030.

The global roller benders market is expected to witness the highest growth in Asia-Pacific with China leading the regional revenue.

The global roller benders market is led by players like Akyapak, Faccin, YSD, Davi, Nanjing Klaus CNC Machinery Co., Ltd, AMB Picot, Uzma Machinery, Nantong Chaoli, Sahinler, Haeusler, Himalaya Machine, Imcar, Roccia, Wuxi Shenchong Forging Machine, and LEMAS.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed