Tablet Dedusters Market Size, Share, Trends, Growth and Forecast 2034

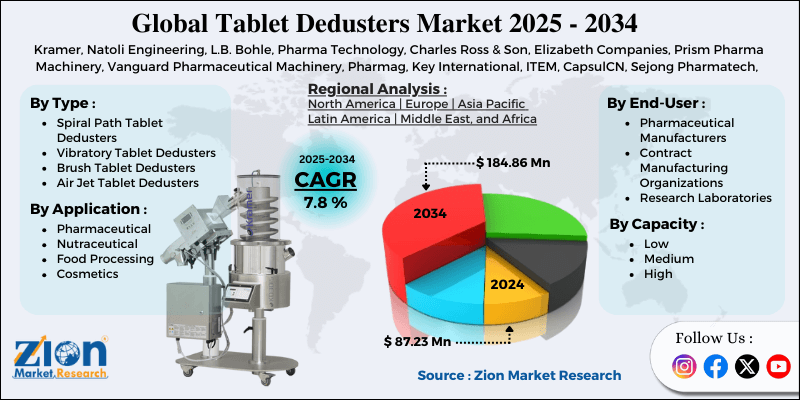

Tablet Dedusters Market By Type (Spiral Path Tablet Dedusters, Vibratory Tablet Dedusters, Brush Tablet Dedusters, and Air Jet Tablet Dedusters), By Application (Pharmaceutical, Nutraceutical, Food Processing, and Cosmetics), By End-User (Pharmaceutical Manufacturers, Contract Manufacturing Organizations, and Research Laboratories), By Capacity (Low, Medium, and High), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2025 - 2034

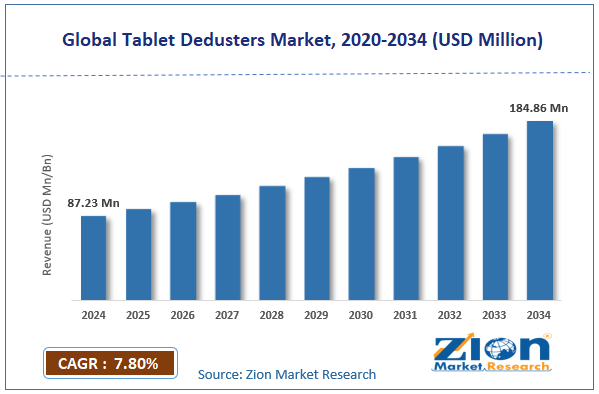

| Market Size in 2024 | Market Forecast in 2034 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 87.23 Million | USD 184.86 Million | 7.80% | 2024 |

Tablet Dedusters Industry Prospective:

The global tablet dedusters market was valued at approximately USD 87.23 million in 2024 and is expected to reach around USD 184.86 million by 2034, growing at a compound annual growth rate (CAGR) of 7.80% between 2025 and 2034.

Tablet Dedusters Market: Overview

Tablet dedusters are pharmaceutical equipment that removes dust, particles, and tablet fragments from finished tablets during the manufacturing process to ensure product quality, reduce cross-contamination, and improve appearance. This established market has various dedusting technologies, such as spiral path systems, vibratory mechanisms, brush systems, and air jet configurations that will enhance pharmaceutical production efficiency and product quality.

Tablet dedusters provide quality control solutions for solid dosage across the pharmaceutical industry. Increasing regulatory scrutiny, pharmaceutical manufacturing quality standards, and generic medicines drive the growth of the tablet dedusters market.

The focus on contamination prevention, automated inspection systems in pharmaceutical processing lines, and expanding pharmaceutical manufacturing capacities in emerging markets are expected to drive substantial growth in the market over the forecast period.

Key Insights:

- As per the analysis shared by our research analyst, the global tablet dedusters market is estimated to grow annually at a CAGR of around 7.80% over the forecast period (2025-2034)

- In terms of revenue, the global tablet dedusters market size was valued at around USD 87.23 million in 2024 and is projected to reach USD 184.86 million by 2034.

- The tablet dedusters market is projected to grow significantly due to stringent regulatory requirements, increasing pharmaceutical manufacturing output, and technological advancements in tablet dedusting systems across diverse geographic regions.

- Based on type, spiral path tablet dedusters lead the segment and will continue to dominate the global market.

- Based on application, pharmaceutical applications are anticipated to command the largest market share.

- Based on end users, pharmaceutical manufacturers are expected to lead the market during the forecast period.

- Based on region, Europe is projected to dominate the global market during the forecast period.

Tablet Dedusters Market: Growth Drivers

Stringent regulatory requirements and quality standards

Strict quality standards drive growth in the tablet dedusters industry. Pharmaceutical manufacturers are investing in dedusting technologies to ensure compliance with regulatory frameworks.

According to recent industry research, regulatory observations on particulate contamination have prompted equipment upgrades across manufacturing sites. This has accelerated as global health authorities intensified inspection protocols and manufacturers prioritized contamination control.

Good Manufacturing Practices (GMP) are driving demand, with a growing preference for integrated dedusters that provide documentation and validation to support regulatory submissions. The emphasis on traceability and real-time monitoring has also led to increased adoption of dedusters with automated data logging and audit-ready reporting features.

Technological advancements in dedusting efficiency

Innovation transforms tablet dedusting equipment and improves operational performance across pharmaceutical production lines. Multi-stage dedusting systems, automated monitoring capabilities, and validation-friendly designs are gaining traction with modern manufacturers.

Research shows advanced dedusting technology reduces tablet defects and improves downstream packaging. Integration with vision inspection systems, data logging, and remote monitoring is increasing adoption in high-end manufacturing environments, driving the growth of the tablet dedusters industry.

Tablet Dedusters Market: Restraints

High initial investment costs and validation requirements

The considerable capital expenditure of advanced tablet dedusting equipment creates market entry barriers and slows replacement cycles throughout the pharmaceutical manufacturing sector.

Complex validation protocols and regulatory documentation requirements add to implementation timeframes and total ownership costs in the tablet dedusters market. Industry reports show that full dedusting system implementation, including installation qualification and operational qualification, is a significant investment for manufacturers.

Smaller pharmaceutical companies struggle to justify significant equipment upgrades despite the quality benefits, creating market segmentation between large and small manufacturers.

Tablet Dedusters Market: Opportunities

Integration of Industry 4.0 and innovative manufacturing capabilities

Digital transformation presents significant opportunities in the global tablet dedusters industry. Connected dedusting systems with real-time monitoring, predictive maintenance, and data analytics create new segments with considerable growth potential.

For example, manufacturers with IoT-enabled dedusting equipment with production line integration are experiencing enhanced operational efficiency compared to standalone units.

Cloud-based monitoring systems and performance analytics resonate with forward-thinking pharmaceutical manufacturers, increasing engagement among technology-oriented production facilities. Automated adjustment and self-diagnostic functions are also being implemented, further expanding the advanced tablet dedusters industry.

Tablet Dedusters Market: Challenges

Balancing throughput demands with dedusting efficiency

Tablet deduster manufacturers identify processing speed limitations as their primary technical challenge, especially as pharmaceutical manufacturers seek higher production volumes without compromising cleaning efficiency. Equipment designers need to balance between gentle tablet handling and comprehensive dust removal.

Handling complexity increases with diverse tablet shapes, sizes, and formulations; equipment manufacturers report ongoing development efforts to accommodate varied product portfolios with minimal adjustments. As formulation science evolves, new coating materials and tablet compositions create new requirements in the tablet dedusting industry.

Cross-contamination prevention demands higher standards; many facilities require dedicated equipment or extensive cleaning validation for multi-product lines in the pharmaceutical manufacturing sector.

Tablet Dedusters Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Tablet Dedusters Market |

| Market Size in 2024 | USD 87.23 Million |

| Market Forecast in 2034 | USD 184.86 Million |

| Growth Rate | CAGR of 7.80% |

| Number of Pages | 211 |

| Key Companies Covered | Kramer, Natoli Engineering, L.B. Bohle, Pharma Technology, Charles Ross & Son, Elizabeth Companies, Prism Pharma Machinery, Vanguard Pharmaceutical Machinery, Pharmag, Key International, ITEM, CapsulCN, Sejong Pharmatech, Dösing, Thermocon, Kikusui, Nicomac, DPH International, Action Technology, Syntegon Technology, IMA Group, ACG Group, and others. |

| Segments Covered | By Type, By Application, By End User, By Capacity, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2024 |

| Historical Year | 2019 to 2023 |

| Forecast Year | 2025 - 2034 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Tablet Dedusters Market: Segmentation

The global tablet dedusters market is segmented into type, application, end-user, capacity, and region.

Based on type, the market is segregated into spiral path tablets, vibratory tablets, brush tablets, and air jet tablet dedusters. Spiral path tablet dedusters lead the market due to their compact design, efficient dust removal capabilities, low maintenance requirements, and compatibility with high-speed tablet presses, making them ideal for large-scale pharmaceutical production lines.

Based on application, the tablet dedusters industry is divided into pharmaceutical, nutraceutical, food processing, and cosmetics applications. Pharmaceutical applications are expected to lead the market during the forecast period as regulatory requirements and quality standards drive investment in dedicated dedusting equipment across prescription and over-the-counter medication manufacturing.

Based on end users, the tablet dedusters industry is categorized into pharmaceutical manufacturers, contract manufacturing organizations, and research laboratories. Pharmaceutical manufacturers are expected to lead the market since they maintain the most significant production volumes and face the most stringent quality control requirements for finished dosage forms.

Based on capacity, the market is classified into low, medium, and high-capacity systems. Medium capacity systems are expected to lead the market due to their versatility in accommodating varying production batch sizes and broad applicability across different manufacturing environments.

Tablet Dedusters Market: Regional Analysis

Europe to lead the market

Europe leads the global tablet dedusters market due to the region's advanced pharmaceutical manufacturing base, regulatory framework, and emphasis on production quality. Germany, Switzerland, and Italy account for a substantial portion of global pharmaceutical equipment production, with dedicated manufacturing excellence centers. The region has an extensive pharmaceutical manufacturing infrastructure with frequent technology refresh cycles driven by regulatory compliance requirements.

European pharmaceutical manufacturers demonstrate high adoption rates for premium dedusting technologies with advanced validation features, and integrated production line solutions are increasingly standard in new facility designs.

The region's regulatory environment creates strong incentives for contamination control investments; European Medicines Agency guidelines specifically address particulate control requirements. Leading pharmaceutical equipment designers maintain significant European research and development operations, accelerating innovation in the region.

Additionally, the presence of major pharmaceutical companies, emphasis on manufacturing excellence, and focus on product quality contribute to market growth. Technological advancements, such as automated monitoring systems and data integration capabilities, further drive equipment upgrades. Strong export demand for European-manufactured dedusters also reinforces the region's position as a global technology leader in pharmaceutical equipment.

North America is set to grow significantly.

North America is experiencing steady growth in the tablet deduster industry, driven by pharmaceutical manufacturing reshoring initiatives, quality compliance focus, and adoption of technological advancements. The North American tablet dedusters market has consistently grown over the past years, with advanced dedusting technologies gaining market share over basic models.

Contract manufacturing organizations are upgrading their equipment to stay competitive. And pharmaceutical innovation clusters in the U.S. are driving the adoption of continuous manufacturing technology. The region's focus on operational efficiency means manufacturers are looking for high-throughput dedusting solutions that minimize production bottlenecks. T

he robust generics manufacturing sector requires cost-effective yet compliant dedusting solutions for its high-volume production environments. There's growing interest in continuous manufacturing technologies, which is driving demand for specialized tablet-handling equipment that can handle non-traditional production flows.

Regulatory scrutiny from the FDA encourages investment in validated and automated dedusting systems to ensure GMP compliance. Additionally, strong research and development, and increasing demand for personalized medicine are prompting manufacturers to adopt more flexible and precise dedusting solutions.

Recent Market Developments:

- In January 2025, L.B. Bohle expanded its pharmaceutical processing portfolio by launching an advanced tablet deduster system featuring continuous monitoring technology and material-specific customization capabilities for enhanced pharmaceutical product quality assurance.

- In February 2025, Pharma Technology introduced an IoT-enabled tablet dedusting platform integrated with production line monitoring systems, providing manufacturers with real-time particle contamination detection, automated adjustment capabilities, and comprehensive validation documentation.

- In March 2025, Kramer launched a comprehensive modular tablet processing system featuring advanced dedusting technology with interchangeable components, sustainable materials, and optimized configurations for various tablet formats and production environments.

Tablet Dedusters Market: Competitive Analysis

The global tablet dedusters market is led by players like:

- Kramer

- Natoli Engineering

- L.B. Bohle

- Pharma Technology

- Charles Ross & Son

- Elizabeth Companies

- Prism Pharma Machinery

- Vanguard Pharmaceutical Machinery

- Pharmag

- Key International

- ITEM

- CapsulCN

- Sejong Pharmatech

- Dösing

- Thermocon

- Kikusui

- Nicomac

- DPH International

- Action Technology

- Syntegon Technology

- IMA Group

- ACG Group

The global tablet dedusters market is segmented as follows:

By Type

- Spiral Path Tablet Dedusters

- Vibratory Tablet Dedusters

- Brush Tablet Dedusters

- Air Jet Tablet Dedusters

By Application

- Pharmaceutical

- Nutraceutical

- Food Processing

- Cosmetics

By End User

- Pharmaceutical Manufacturers

- Contract Manufacturing Organizations

- Research Laboratories

By Capacity

- Low

- Medium

- High

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Tablet dedusters are specialized pharmaceutical equipment designed to remove dust, particles, and tablet fragments from finished tablets during the manufacturing process, ensuring product quality, reducing cross-contamination, and improving visual appearance.

The tablet dedusters market is expected to be driven by increasing regulatory scrutiny, growing pharmaceutical manufacturing capacities, technological advancements in tablet handling and cleaning systems, expanding generic drug production, and a rising focus on contamination prevention in pharmaceutical manufacturing.

According to our study, the global tablet dedusters market was worth around USD 87.23 million in 2024 and is predicted to grow to around USD 184.86 million by 2034.

The CAGR value of the tablet dedusters market is expected to be around 7.80% during 2025-2034.

The global tablet dedusters market will register the highest growth in Europe during the forecast period.

Key players in the tablet dedusters market include Kramer, Natoli Engineering, L.B. Bohle, Pharma Technology, Charles Ross & Son, Elizabeth Companies, Prism Pharma Machinery, Vanguard Pharmaceutical Machinery, Pharmag, Key International, ITEM, CapsulCN, Sejong Pharmatech, Dösing, Thermocon, Kikusui, Nicomac, DPH International, Action Technology, Syntegon Technology, IMA Group, and ACG Group.

The report comprehensively analyses the tablet dedusters market, including an in-depth discussion of market drivers, restraints, emerging trends, regional dynamics, and future growth opportunities. It also examines competitive dynamics, technological innovations, and the evolving manufacturer preferences shaping the pharmaceutical equipment ecosystem.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed