Welding Robotics Market Size, Share, Trends, Growth and Forecast 2030

Welding Robotics Market By Type (Spot, Laser, Arc, MIG/TIG, and Others), By Payload Capacity (Low (6kg-22kg), Medium (30kg-60kg), and High (80kg-300kg)) By End-User (Automotive, Construction, Railway & Shipbuilding, Aerospace & Defense, Mining, Electrical & Electronics, and Others), and By Region - Global and Regional Industry Overview, Market Intelligence, Comprehensive Analysis, Historical Data, and Forecasts 2023 - 2030

| Market Size in 2022 | Market Forecast in 2030 | CAGR (in %) | Base Year |

|---|---|---|---|

| USD 6 Billion | USD 15 Billion | 8% | 2022 |

Welding Robotics Industry Prospective:

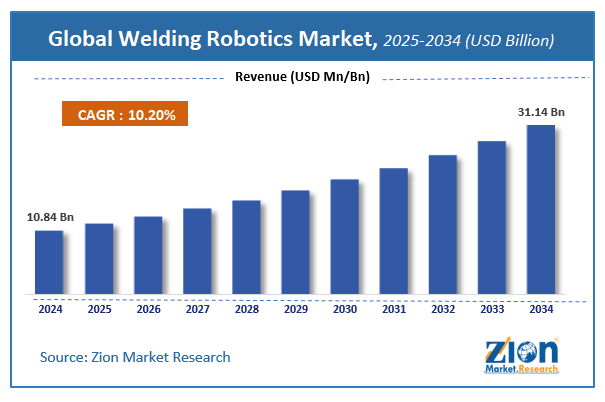

The global welding robotics market size was evaluated at $6 billion in 2022 and is slated to hit $15 billion by the end of 2030 with a CAGR of nearly 8% between 2023 and 2030.

Welding Robotics Market: Overview

Welding robotics automates the process of welding for increasing accuracy, thereby improving accuracy and safety along with reducing the time required for completing each project. All these advantages make the welding robotic process the most popular alternative for manual metal joining. In addition to this, the rise in the use of welding has enhanced the output of welding lines and resulted in severe workplace collisions. For the record, welding robotics is widely utilized in metal, electronics, automotive, aerospace, and fabrication applications, thereby reducing costs and saving the processing time of manufacturing operations.

Key Insights

- As per the analysis shared by our research analyst, the global welding robotics market is projected to expand annually at the annual growth rate of around 8% over the forecast timespan (2023-2030)

- In terms of revenue, the global welding robotics market size was evaluated at nearly $6 billion in 2022 and is expected to reach $15 billion by 2030.

- The global welding robotics market is anticipated to easy access to facial treatment along with enhanced consciousness about new techniques.

- In terms of type, the arc segment is slated to register the highest CAGR over the analysis period.

- Based on the payload capacity, the medium (30kg-60kg) segment is anticipated to dominate the segment over the projected period.

- Based on the end-user, the automotive segment is anticipated to dominate the segment over the projected period.

- Region-wise, the North American welding robotics industry is projected to register the fastest CAGR during the assessment timeline.

Request Free Sample

Request Free Sample

Welding Robotics Market: Growth Factors

An increase in the adoption of Industry 4.0 technologies has prompted the global market demand

The rise in the acceptance of Industry 4.0 principles has resulted in demand for welding robots in the transport and automotive sectors, thereby steering the growth of the welding robotics market across the globe. For instance, in the second half of 2020, ABB India declared the opening of a new robotics unit for supporting the digital transformation of manufacturing processes in India by using Industry 4.0 concepts that include the use of robotics and online systems. Breakthroughs in the automation systems as well as automated processes have paved the way for humungous expansion of the market across the globe. In addition to this, growing costs of labor along with the need for the safety of workers have translated into massive use of welding robots in a slew of manufacturing processes. New product launches have shaped the growth of every business and welding robotics is no exception to this. For instance, Kemppi Oy, a Finland-based welding firm, launched Kemppi AX MIG Welder, a strong robotic welder having seamless integration and an easy-to-use tool along with upgraded welding systems.

Welding Robotics Market: Restraints

The need for huge funding for purchasing welding robots can hinder global industry growth by 2030

The requirement of huge initial investments for procuring, maintaining, and programming welding robots can put brakes on the expansion of the welding robotics industry globally. In addition to this, low acceptance of welding robots by small & medium-scale firms can further put brakes on global industry trends.

Welding Robotics Market: Opportunities

Huge adoption of welding robots in transport & shipbuilding sectors will open new facets of growth for the global market by 2030

The evolution of new technologies such as plasma welding and laser will increase the scope of opportunities for the welding robotics market across the globe. Massive demand for welding robots in shipbuilding and transport sectors will further scoop up the global industry trends.

Welding Robotics Market: Challenges

Less access to experts can prove to be a big challenge for the global industry in the near future

Low availability of skilled workforce can prove to be a challenging task for operating welded robots, thereby curtailing the welding robotics industry demand globally. Perceived resistance to using robots among workers and protests by them against their use due to fear of losing jobs can further create a huge challenge for global industry expansion.

Welding Robotics Market: Segmentation

The global welding robotics market is sectored into type, payload capacity, end-user, and region.

In type terms, the global welding robotics market is segregated into spot, laser, arc, MIG/TIG, and others segments. Furthermore, the arc segment, which garnered nearly half of the global market share in 2022, is predicted to record the fastest CAGR in the ensuing years. The growth of the segment in the upcoming years can be owing to the large-scale penetration of arc welding in the automotive and other end-use industries that require precision.

Based on payload capacity, the global welding robotics industry is bifurcated into low (6kg-22kg), medium (30kg-60kg), and high (80kg-300kg) segments. Moreover, the medium (30kg-60kg) segment, which contributed remarkably towards the global industry revenue in 2022, is set to dominate the global industry surge over the assessment timeline. The segmental expansion over the estimated timeline can be owing to a rise in the use of medium (30kg-60kg) payload capacity in automotive and other end-use sectors during extreme climatic conditions.

Based on the end-user, the global welding robotics market is divided into automotive, electrical & electronics, construction, aerospace & defense, railway & shipbuilding, mining, and others segments. Moreover, the automotive segment, which accumulated a huge share of the global market in 2022, is anticipated to lead the global market expansion over the projected timeline. The segmental growth over the estimated timeline can be subject to massive demand for welding robots in automotive production activities. The need for quick assembling of automotive components and spot welding has increased the demand for welding robots in the automotive segment.

Welding Robotics Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Welding Robotics Market |

| Market Size in 2022 | USD 6 Billion |

| Market Forecast in 2030 | USD 15 Billion |

| Growth Rate | CAGR of 8% |

| Number of Pages | 231 |

| Key Companies Covered | Fanuc Corporation, IGM ROBOTERSYSTEME AG, Kuka AG, Yaskawa Electric Corporation, Estun Automation Co. Ltd., UNITED PROARC CORPORATION, EVS TECH CO. LTD., Daihen Corporation, Kawasaki Heavy Industries Ltd., Panasonic Corporation, NACHI-FUJIKOSHI CORP., ABB Ltd., and others. |

| Segments Covered | By Type, By End-User, By Payload Capacity, and By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2022 |

| Historical Year | 2017 to 2021 |

| Forecast Year | 2023 - 2030 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Welding Robotics Market: Regional Insights

Asia-Pacific is projected to retain its global market leadership over the estimated timeframe

Asia-Pacific, which accounted for 65% of the global welding robotics market revenue in 2022, will be the dominating region over the assessment timeline. Moreover, the regional market growth can be credited to surging industrial automation in Japan, South Korea, China, and Taiwan. Moreover, the use of Industry 4.0 techniques will augment the expansion of the market in the region. Additionally, the presence of key players in the region will account majorly towards the regional market growth in the upcoming years.

North American welding robotics industry is set to register the fastest CAGR in the next couple of years subject to a rise in the allocation of funds on research activities related to automated processes and automated devices such as industrial robots in countries such as the U.S.

Welding Robotics Market: Competitive Space

The global welding robotics market profiles key players such as:

- Fanuc Corporation

- IGM ROBOTERSYSTEME AG

- Kuka AG

- Yaskawa Electric Corporation

- Estun Automation Co. Ltd.

- UNITED PROARC CORPORATION

- EVS TECH CO. LTD.

- Daihen Corporation

- Kawasaki Heavy Industries Ltd.

- Panasonic Corporation

- NACHI-FUJIKOSHI CORP.

- ABB Ltd.

The global welding robotics market is segmented as follows:

By Type

- Spot

- Laser

- Arc

- MIG/TIG

- Others

By End-User

- Automotive

- Construction

- Railway & Shipbuilding

- Aerospace & Defense

- Mining

- Electrical & Electronics

- Others

By Payload Capacity

- Low (6kg-22kg)

- Medium (30kg-60kg)

- High (80kg-300kg)

By Region

- North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

Welding robotics automates the process of welding for increasing accuracy, thereby improving accuracy and safety along with reducing the time required for completing each project.

The global welding robotics market growth can be owing to breakthroughs in automation systems as well as automated processes.

According to a study, the global welding robotics industry size was $6 billion in 2022 and is projected to reach $15 billion by the end of 2030.

The global welding robotics market is anticipated to record a CAGR of nearly 8% from 2023 to 2030.

The North American welding robotics industry is set to register the highest CAGR over the forecasting timeline owing to a rise in the allocation of funds on research activities related to automated processes and automated devices such as industrial robots in countries such as the U.S.

The global welding robotics market is led by players such as Fanuc Corporation, IGM ROBOTERSYSTEME AG, Kuka AG, Yaskawa Electric Corporation, Estun Automation Co., Ltd., UNITED PROARC CORPORATION, EVS TECH CO., LTD., Daihen Corporation, Kawasaki Heavy Industries, Ltd., Panasonic Corporation, NACHI-FUJIKOSHI CORP., and ABB Ltd.

The welding robotics market report covers the geographical market along with a comprehensive competitive landscape analysis. It also includes cash flow analysis, profit ratio analysis, market basket analysis, market attractiveness analysis, sentiment analysis, PESTEL analysis, trend analysis, SWOT analysis, trade area analysis, demand & supply analysis, Porter’s five force analysis, and value chain analysis.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed