Egg Processing Market Size, Share, Growth Analysis, Forecast Report 2024-2032

Egg Processing Market by Type (Frozen Egg Products, Dried Egg Products, Refrigerated Liquid Egg Products, Plain Unstabilised Whole Egg Products, Specialty Egg Products) by Application (Dairy Products, Bakery & Confectionery, Soup & Sauces, Ready to Eat, Others): Global Industry Perspective, Comprehensive Analysis and Forecast, 2024 - 2032-

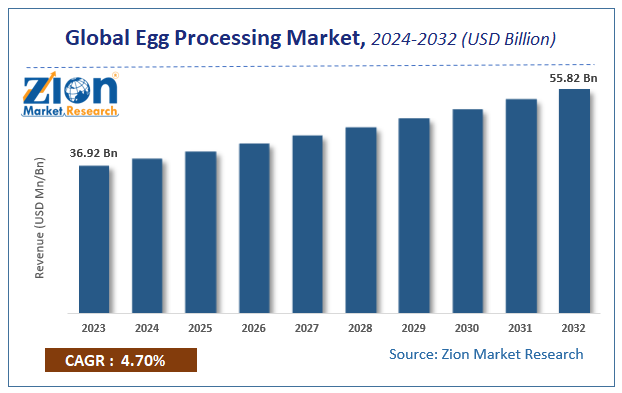

| Market Size in 2023 | Market Forecast in 2032 | CAGR (in %) | Base Year |

|---|---|---|---|

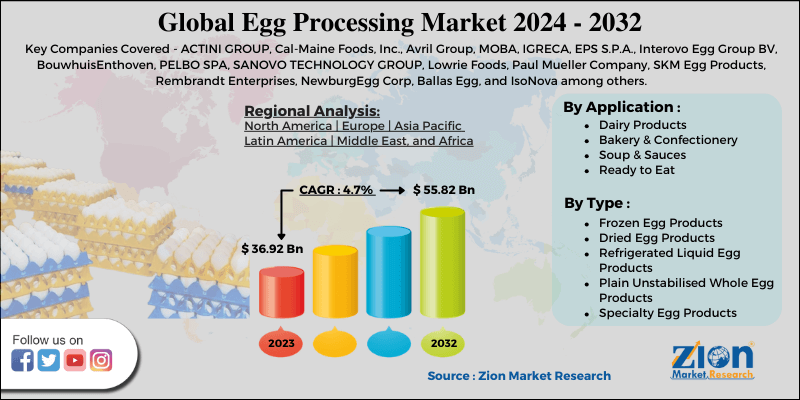

| USD 36.92 Billion | USD 55.82 Billion | 4.7% | 2023 |

Egg Processing Market Insights

According to a report from Zion Market Research, the global Egg Processing Market was valued at USD 36.92 Billion in 2023 and is projected to hit USD 55.82 Billion by 2032, with a compound annual growth rate (CAGR) of 4.7% during the forecast period 2024-2032.

This report explores market strengths, weakness, opportunities, and threats. It also provides valuable insights into the market's growth drivers, challenges, and the future prospects that may emerge in the Egg Processing Market industry over the next decade.

Global Egg Processing Market: Overview

Egg processing is an industrial and high-tech activity that requires expertise and experience. Achieving high quality liquid or egg powder products is a matter of recognising the different stages of the process.

Eggs for processing must be of high quality in order to prevent unnecessary yolk breakage in egg-breaking systems. A fresh egg consists of a thick egg white and an upright yolk. Over time, the egg white thins and the yolk expands due to the flow of water from the white to the yolk membrane which weakens the yolk. Eggs to be processed are normally kept in refrigerated storage for no more than 7 to 10 days.

Breaking the egg, filtering, mixing, stabilizing, blending, pasteurizing, cooling, freezing or drying, as well as packaging are all steps in the egg manufacturing process. The most common varieties of egg products are liquid, frozen, and dry egg products, which come in whole eggs, whites, yolks, and various mixtures. These egg products are frequently utilized as ingredients in goods such as pasta, noodles, salad dressings, and dairy products in the food and beverage industry. Egg breakers, egg fillers, egg pasteurizers, and egg handling and storage machinery are examples of egg processing equipment.The egg processing industry is expanding in tandem with consumer demand for higher-quality, cleaner products. New products are constantly being produced in response to demand, with a strong emphasis on innovation and product usefulness. The rise in demand for egg products is driving the egg processing market. The growth is due to the assurance of safety, reduced danger of contamination, and extended shelf-life of processed egg products. The market is also being driven by an expansion in the use of processed egg products in the food and beverage industry.

Egg products are prepared in proper hygienic facilities under a strict inspection regime. As per American Egg Board (AEB), this is regulated by the United States Department of Agriculture (USDA) in the USA. Regulations include the implementation of 3-A Sanitary Standards & 3-A Accepted Practices for processing equipment. They are often used to assess the approval of the design of equipment, widely used in the dairy and egg products industries. These guidelines have been set by the International Association for Food Protection and USDA. Some regulations are variations of those of the International Dairy Foods Association (IDFA) and The Food Processing Suppliers Association (FPSA) and others are exclusive to the egg industry, such as egg-breaking equipment.

Global Egg Processing Market: Growth Factors

The global egg processing market is expected to grow due to shift in consumer preferences and tastes for processed food, along with an increase in demand for high-quality real egg products in the coming years. As demand for protein-rich food and dietary supplements grows, the global demand for egg processing is anticipated to escalate over the forecast period. Advancement in technologies is expected to have a positive effect on the demand growth during the conjecture period. Companies in the egg processing industry are introducing high-quality production processes and are constantly engaged in product development. As demand rises, key players concentrate on introducing high-end goods, such as automated assembly lines that boost production speed and reduce operating costs. This is expected to boost the growth of the global egg processing market.

The demand for egg processing is predicted to reach at a significant pace in the coming years. This is mainly due to many benefits of processed eggs, such as long shelf life, reduced risk of contamination, and ease of transportation. Moreover, the increase in the use of eggs in the dairy and bakery & confectionery industry is another factor that stimulates the demand for egg processing market. Strict regulatory requirements for materials and equipments used in egg processing to increase public awareness of the nutritional advantages and high quality of eggs, thereby supporting the growth of egg processing market.

Furthermore, as the operation of identification and classification of eggs get implemented across various egg processing industry in order to remove the use of unsafe eggs, the market is gaining significant momentum, contributing to the growth of the global egg processing market. With the use of these method, the unhealthy contaminated eggs are removed as it can lead to food infections and other microbiological risks. As eggs are best source of protein in the diet, barriers are expected to be overcome in the egg processing industry with growing demand for dietary supplements across the globe. The introduction of new and advanced egg production technologies that minimize egg waste will create potential opportunities for major players in the global egg processing market.

Global Egg Processing Market: Segmentation

Refrigerated liquid egg products can be directly supplied from the egg breaking plant to the customer in sealed thermal tank trucks or in portable refrigerated tubs. Mechanical refrigeration, liquid-nitrogen cooling systems or liquid-carbon-dioxide can be used for long hauls.

Refrigerated liquid egg products can be kept unopened for two to six days at 40°F (4.4°C) for whole eggs and yolks or 45°F (7.2°C) for whites, depending on the microbial content of the commodity. Refrigerated liquid egg items with a long shelf life should be kept refrigerated and stored according to the manufacturer's instructions.

Frozen egg products are made by filling a jar with chilled pasteurised liquid egg and freezing it at –10° to –40°F (–23.3° to –40°C) in a blast freezer. Frozen whole eggs get quite fluid and simple to handle when thawed, however frozen raw yolk will have a gelatinized consistency when thawed. When a yolk is mixed with corn syrup, sugar or salt (typically in the range of 2% to 10%) before freezing, the result is a fluid product when thawed.

Although some egg white is dried on trays to create a granular or flake texture, most dried egg products are created by spray drying. Glucose is extracted from the egg white until it is dried. This results in dried egg white items that are extremely stable in storage. For strong whipping properties, whipping aids may be applied to dried egg white products. Prior to drying, sodium lauryl sulphate, an angel food cake volume additive, is included at a concentration of less than 0.1% by weight of the liquid. Glucose is extracted from whole egg and yolk products before drying when long storage stability is necessary. Some products have non-reducing carbohydrates added to them, such as glucose-free sucrose and corn syrup, to keep their whipping properties and increase their shelf life.

Egg Processing Market: Report Scope

| Report Attributes | Report Details |

|---|---|

| Report Name | Egg Processing Market |

| Market Size in 2023 | USD 36.92 Billion |

| Market Forecast in 2032 | USD 55.82 Billion |

| Growth Rate | CAGR of 4.7% |

| Number of Pages | 110 |

| Key Companies Covered | ACTINI GROUP, Cal-Maine Foods, Inc., Avril Group, MOBA, IGRECA, EPS S.P.A., Interovo Egg Group BV, BouwhuisEnthoven, PELBO SPA, SANOVO TECHNOLOGY GROUP, Lowrie Foods, Paul Mueller Company, SKM Egg Products, Rembrandt Enterprises, NewburgEgg Corp, Ballas Egg, and IsoNova among others. |

| Segments Covered | By Type, By Application, And By Region |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Base Year | 2023 |

| Historical Year | 2018 to 2022 |

| Forecast Year | 2024 - 2032 |

| Customization Scope | Avail customized purchase options to meet your exact research needs. Request For Customization |

Global Egg Processing Market: Regional Analysis

By Geography, the egg processing market is segmented into North America, Europe, Latin America, Asia Pacific, and Middle East and Africa.

The egg processing market in North America has seen strong growth in the consumption of eggs and egg products, which has aided the market's growth in recent years. Other important driving factors include technological innovations, developing markets, and new product launches. On the other hand, the industry faces obstacles such as extensive government regulations, strict food safety laws, and animal welfare regulatory requirements. These factors also stifled the market's ability to achieve its full potential.

Global Egg Processing Market: Competitive Players

Some of the leading players in the global market inlcude

- ACTINI GROUP

- Cal-Maine Foods Inc.

- Avril Group

- MOBA

- IGRECA

- EPS S.P.A.

- Interovo Egg Group BV

- BouwhuisEnthoven

- PELBO SPA

- SANOVO TECHNOLOGY GROUP

- Lowrie Foods

- Paul Mueller Company

- SKM Egg Products

- Rembrandt Enterprises

- NewburgEgg Corp

- Ballas Egg

- IsoNova

The report segment of global egg processing market are as follows:

By Type Segment Analysis

- Frozen Egg Products

- Dried Egg Products

- Refrigerated Liquid Egg Products

- Plain Unstabilised Whole Egg Products

- Specialty Egg Products

By Application Segment Analysis

- Dairy Products

- Bakery & Confectionery

- Soup & Sauces

- Ready to Eat

- Others

By Regional Segment Analysis

-

North America

- The U.S.

- Canada

- Europe

- France

- The UK

- Spain

- Germany

- Italy

- Rest of Europe

- Asia Pacific

- China

- Japan

- India

- South Korea

- Southeast Asia

- Rest of Asia Pacific

- Latin America

- Brazil

- Mexico

- Rest of Latin America

- Middle East & Africa

- GCC

- South Africa

- Rest of Middle East & Africa

Table Of Content

Methodology

FrequentlyAsked Questions

The global egg processing market is expected to grow due to shift in consumer preferences and tastes for processed food, along with an increase in demand for high-quality real egg products in the coming years. As demand for protein-rich food and dietary supplements grows, the global demand for egg processing is anticipated to escalate over the forecast period. Advancement in technologies is expected to have a positive effect on the demand growth during the conjecture period. Companies in the egg processing industry are introducing high-quality production processes and are constantly engaged in product development. As demand rises, key players concentrate on introducing high-end goods, such as automated assembly lines that boost production speed and reduce operating costs. This is expected to boost the growth of the global egg processing market.

Egg Processing Market size worth at USD 36.92 Billion in 2023 and projected to USD 55.82 Billion by 2032, with a CAGR of around 4.7% between 2024-2032.

The egg processing market in North America has seen strong growth in the consumption of eggs and egg products, which has aided the market's growth in recent years. Other important driving factors include technological innovations, developing markets, and new product launches. On the other hand, the industry faces obstacles such as extensive government regulations, strict food safety laws, and animal welfare regulatory requirements. These factors also stifled the market's ability to achieve its full potential.

The major players in the global egg processing market include ACTINI GROUP, Cal-Maine Foods, Inc., Avril Group, MOBA, IGRECA, EPS S.P.A., Interovo Egg Group BV, BouwhuisEnthoven, PELBO SPA, SANOVO TECHNOLOGY GROUP, Lowrie Foods, Paul Mueller Company, SKM Egg Products, Rembrandt Enterprises, NewburgEgg Corp, Ballas Egg, and IsoNova among others.

HappyClients

Zion Market Research

Tel: +1 (302) 444-0166

USA/Canada Toll Free No.+1 (855) 465-4651

3rd Floor,

Mrunal Paradise, Opp Maharaja Hotel,

Pimple Gurav, Pune 411061,

Maharashtra, India

Phone No +91 7768 006 007, +91 7768 006 008

US OFFICE NO +1 (302) 444-0166

US/CAN TOLL FREE +1 (855) 465-4651

Email: sales@zionmarketresearch.com

We have secured system to process your transaction.

Our support available to help you 24 hours a day, five days a week.

Monday - Friday: 9AM - 6PM

Saturday - Sunday: Closed